For builders, contractors, and remodelers in the Bay Area, managing construction and demolition (C&D) waste can feel like just another box to check. But what if you thought about it differently? Instead of a chore, smart debris recycling is a powerful business strategy that can boost your bottom line and reputation.

This guide is designed for professionals like you working in Berkeley, Oakland, and across the San Francisco Bay Area. We'll explore how to fine-tune your operations to benefit both the environment and your bank account.

Why Smart Debris Recycling Matters for Bay Area Builders

In a competitive market like the Bay Area, a well-managed job site stands out. A thoughtful plan to recycle construction debris directly impacts your profitability. When you divert materials like clean wood, concrete, and metal away from the landfill, you sidestep hefty disposal fees.

These savings can be substantial. On projects with significant demolition, like many new roof installations or major remodels, planning for debris recycling from day one can lead to major cost reductions.

The scale of this is staggering. The U.S. Environmental Protection Agency (EPA) estimates that the U.S. generated 600 million tons of C&D debris in 2018. Materials we handle every day—wood, concrete, asphalt—make up a massive portion of that debris, putting our local efforts into a much bigger perspective.

Recycling Potential of Common Job Site Materials

To help you visualize what's possible on your own projects, here’s a quick-reference table for common materials we see on job sites and what you can do with them.

| Material | Typical End-of-Life Option | Bay Area Tip |

|---|---|---|

| Clean Wood & Lumber | Can be chipped for mulch, biomass fuel, or compost. | Many local facilities accept clean wood. Keep it separate from treated or painted wood to avoid contamination. |

| Concrete & Asphalt | Crushed and reused as aggregate for new concrete, road base, or fill. | Ask your C&D recycler if they crush on-site or can direct you to the nearest facility. This saves on hauling costs. |

| Metals (Steel, Copper, Aluminum) | Highly recyclable. Can be melted down and reformed into new products. | Metal recycling is often profitable. Separate ferrous (magnetic) and non-ferrous metals for the best prices. |

| Drywall (Gypsum) | Can be ground up and used as a soil amendment or in new drywall. | Keep it dry! Wet drywall is much harder to recycle. Cover your drywall bin if rain is in the forecast. |

This isn't an exhaustive list, but it shows how a little sorting on-site can make a huge difference in where these materials end up.

Aligning with Bay Area Sustainability Goals

In a region that prides itself on environmental leadership, how you manage waste says a lot about your business. Homeowners and developers are increasingly looking for partners who share their values. When you can show a real commitment to recycling, you build trust and boost your brand’s reputation.

This approach is also fundamental for meeting local green building standards like California's CALGreen code. Integrating sustainable practices is a core part of modern, responsible construction. Ultimately, this turns a regulatory headache into a clear business advantage.

Creating Your On-Site Waste Management Blueprint

A solid plan to recycle construction debris starts long before the first wall comes down. A good blueprint integrates waste management right into your workflow, making it an efficient part of the job. The goal is to make sorting a natural reflex for your crew, not a last-minute scramble.

Conduct a Pre-Project Waste Audit

This process kicks off with a pre-project waste audit. It’s a practical site walkthrough to estimate the types and amounts of materials you'll generate. This assessment helps you order the right number and size of collection bins, saving you from costly overages.

A well-executed waste audit is the foundation of your entire recycling strategy. It’s not just about estimating volume; it’s about anticipating the flow of materials off-site, which allows you to schedule pickups efficiently and keep your project on track.

Set Up Your Site for Sorting Success

Once you know what to expect, it’s all about strategic placement. Position separate, clearly labeled bins for your main materials—think clean wood, metal, concrete, and cardboard. Place them in accessible, high-traffic areas to make it easy for your crew to sort correctly.

For example, a kitchen remodel in an old Oakland Victorian will produce different debris than a new build in Berkeley. The Victorian job might yield valuable old-growth redwood siding, plus plaster and lath, each needing a unique disposal path. Choosing the right contractor durable materials from the start also helps minimize waste.

Assign Roles and Responsibilities

A plan is only as good as the team running it. Assign an on-site point person to manage the waste plan. This person ensures bins are used correctly, educates subcontractors, and monitors for contamination.

Clear communication is key. A quick tailgate talk can get everyone on the same page. Explain the why behind sorting—it saves money, ensures compliance, and keeps the client happy. To help with costs, it’s worth looking into grants for waste prevention which can offset the expense of a top-notch recycling program.

Mastering On-Site Sorting to Maximize Value

Effective on-site sorting is the most critical step to getting the most value when you recycle construction debris. Separating materials at the source is how you’ll hit high recycling rates and keep your disposal costs down on any Bay Area project. This isn't just about being green; it's smart business.

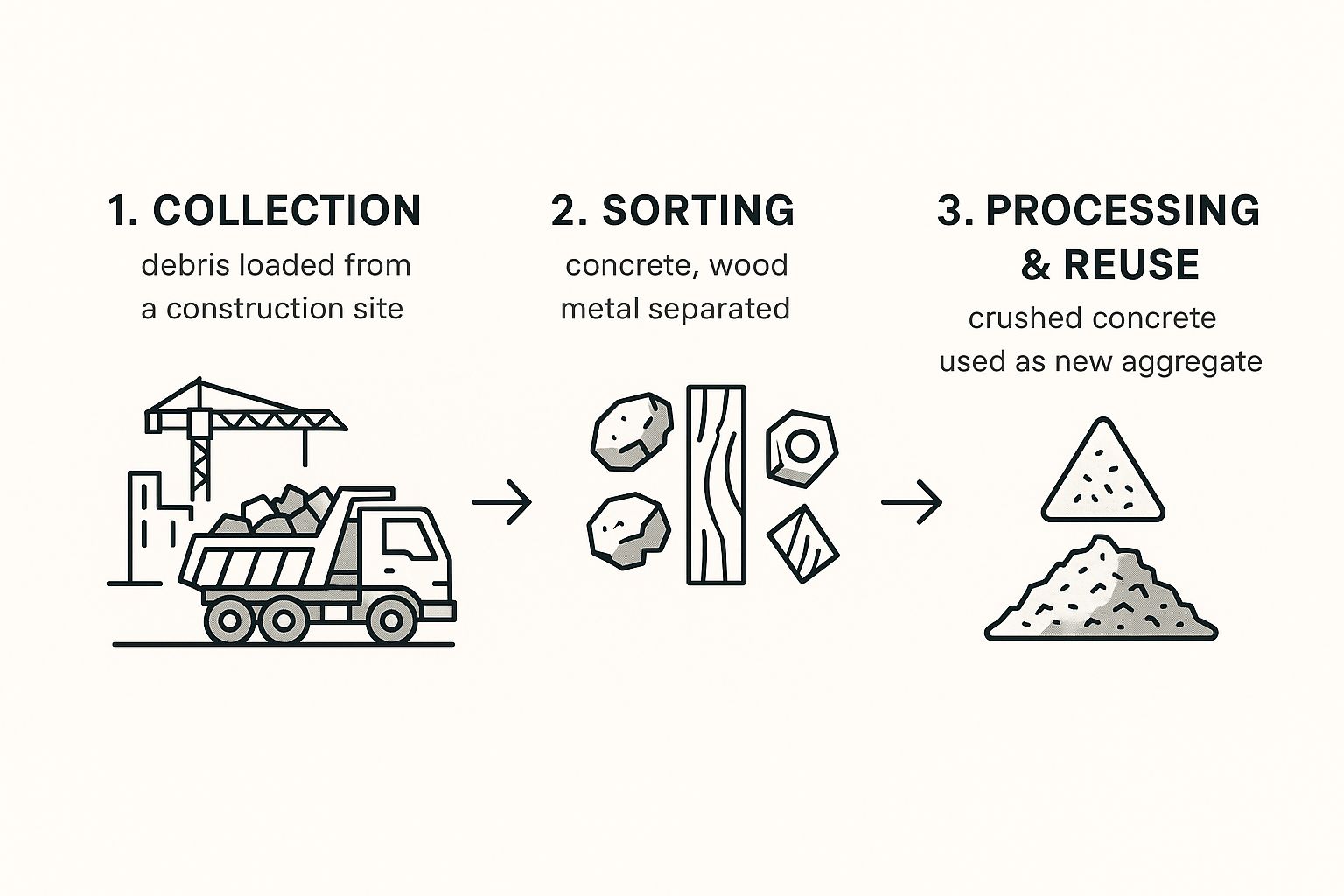

This infographic breaks down how these materials journey from your job site back into the supply chain.

When materials are sorted properly, they have a direct path to becoming new products. This keeps them out of our landfills and cuts down on the need for virgin resources.

A Field Guide to Sorting Key Materials

Success boils down to how you handle a few key materials. Each has specific rules, and following them is essential for getting your loads accepted at recycling facilities in Berkeley, Oakland, and across the Bay.

- Clean Wood & Lumber: Keep untreated and unpainted wood completely separate. This means no pressure-treated lumber, no trim with lead-based paint, and no engineered wood like OSB or MDF mixed in. De-nailing lumber on-site also makes it more valuable.

- Concrete & Asphalt: The golden rule here? No contaminants. Dirt, wood scraps, rebar, and general trash will get your whole load rejected at the C&D facility.

- Metals: This is often where you can get a direct financial payback. Keep ferrous metals (like steel studs) separate from more valuable non-ferrous metals (like copper pipes and aluminum siding). A simple magnet is all you need—if it sticks, it’s ferrous.

- Cardboard: Always break down your boxes and, most importantly, keep them dry. A dedicated, covered bin for cardboard is a simple move that pays off, especially with our unpredictable Bay Area weather.

Starting your project with the right materials can also make your waste management plan much smoother. When you source from a dependable supplier, you can better predict your packaging and offcut waste. We recommend looking into our deep inventory of building material supplies in San Francisco to set your project up for success.

Critical Tip: The most common and costly mistake is contaminating a clean load. Just one wrong item—a can of paint or any hazardous material—can force the recycling facility to reject the entire dumpster. That means it goes straight to the landfill, and you get hit with a much higher disposal fee.

Finding the Right Bay Area Recycling Facilities and Haulers

Your on-site sorting efforts are only as good as the partners you choose to haul and process the materials. Your hauler and recycling facility are the final, critical links in the chain. The Bay Area has a great network of facilities, but they aren’t all created equal.

Finding the right fit is about matching what you’re disposing of to what a facility specializes in. For a mixed-use job, a co-mingled roll-off service is convenient. But if you’re generating tons of clean concrete or scrap metal, a specialized hauler might offer better rates.

Pro Tip: Always call the facility or check their website for an up-to-date list of accepted materials before you send a truck over. A rejected load costs you time, extra hauling fees, and usually ends with your carefully sorted materials going to a landfill.

How to Vet Local Haulers and Facilities

When you're looking for a partner in Berkeley, Oakland, or Richmond, you need to ask the right questions. Don’t just look at the price per ton.

Here’s what you should ask:

- Recycling Reports: Can they provide clear documentation of their recycling rates? This is often a requirement for green building certifications and city compliance.

- Contamination Rules: What are their specific policies on contamination? Knowing their thresholds helps you train your crew effectively.

- Accepted Materials List: Get specific. Do they handle the particular materials from your job site, like treated wood, mixed C&D drywall, or asphalt shingles?

Organizations that champion green building are fantastic resources for finding reputable partners. We’ve seen how groups like Build It Green, a local non-profit we proudly support, help push for more sustainable building in our community. Taking a few extra minutes to properly vet your partners ensures all your hard work pays off.

The Future Is Circular: How Recycled Materials Are Reshaping Construction

The effort you put into sorting materials doesn't just end when the hauler leaves. It’s the first step in a powerful movement: the circular economy. This is where your separated debris gets a second life, re-entering the supply chain as a valuable commodity.

This shift is already reshaping how we build. The market to recycle construction debris is not a niche concept; it’s a massive global industry. According to some projections, the global market for construction waste recycling could reach billions in the coming years. If you’re curious, you can dig into the numbers and see how market demand is driving this change with more information from Data Insights Market.

Turning Debris into Demand

Smart contractors are already capitalizing on this. They've stopped thinking about "waste disposal" and started seeing themselves as suppliers of raw materials.

Here's what happens to that sorted debris:

- Crushed Concrete Aggregate: Your clean concrete rubble becomes the new road base for projects across California or gets mixed into new concrete.

- Recycled Steel: Scrap metal from a demolition is melted down and re-forged into new structural steel and rebar.

- Engineered Wood Products: Clean, salvaged wood fiber is repurposed into particleboard and other composite materials, reducing the need for virgin timber.

This creates a powerful feedback loop. The more efficiently we recycle, the more available and cost-effective these sustainable materials become for everyone.

By treating your job site debris as a future resource, you position your business at the forefront of a more resourceful and resilient construction industry. It's a strategic move that benefits your bottom line and aligns with the sustainable values of clients in Berkeley, Oakland, and beyond.

Your Bay Area C&D Recycling Questions Answered

We’ve compiled answers to the most common questions we hear from builders and contractors about how to recycle construction debris in the Bay Area. For more general questions, you can always visit our main company FAQ page.

What's the difference between source-separated and co-mingled recycling?

Source-separated recycling means you sort materials into different bins on-site (wood, metal, concrete, etc.). Co-mingled recycling means all your debris goes into a single bin and is sorted later at a specialized facility. While co-mingled seems easier, source-separating on-site almost always leads to cleaner materials and lower disposal fees.

Can I recycle old plaster and lath from a Bay Area remodel?

This is a common question for projects in older homes in San Francisco or Oakland. Clean wood lath is often recyclable once separated. However, most facilities consider old plaster (especially with horsehair binders) to be landfill waste. Always check with your local recycling facility to confirm their rules before mixing these materials.

Are there any materials I should never put in a C&D recycling bin?

Yes, absolutely. Hazardous materials can contaminate an entire load, leading to rejection, high fees, and potential fines. Always handle these items separately: materials containing asbestos, wood with lead-based paint, pressure-treated lumber, liquid chemicals, and e-waste.

How do I find a certified C&D recycling facility near my Berkeley job site?

Your city's public works or environmental services website is a great starting point, as they usually list approved local facilities. The state’s CalRecycle database is another excellent resource for finding certified processors throughout California. Don’t hesitate to ask your waste hauler for recommendations, too.

What are the CALGreen requirements for C&D recycling?

The California Green Building Standards Code (CALGreen) requires construction projects to divert at least 65% of their C&D waste from landfills. This can be achieved through recycling and salvaging materials. Keeping detailed records and using certified facilities are crucial for proving compliance on your Bay Area projects.

For expert advice on your next project or to source high-quality Berkeley building materials that align with your sustainability goals, the team at Truitt & White is here to help. Visit our Berkeley showroom for expert advice.