What exactly is engineered wood? Simply put, it’s a family of advanced building materials made by bonding together wood fibers, veneers, or strands with powerful industrial adhesives. This process uses intense heat and pressure to create products that are often superior to what a single piece of solid wood can offer.

Think of it as a high-performance alloy, but for construction. The result is building materials that are stronger, straighter, and more dimensionally stable than most traditional lumber.

Why Engineered Wood is a Go-To for Bay Area Construction

For builders, architects, and contractors in the Bay Area, engineered wood is often a necessity. Our region’s demanding climate, strict seismic codes, and high standards for sustainability require materials that perform reliably. Engineered wood steps up to meet these challenges.

It provides a predictable alternative to solid lumber for everything from framing and flooring to critical structural components. This guide will unpack why this "Berkeley building material" is so critical for projects across Oakland and the greater San Francisco area.

The superpower of engineered wood is its dimensional stability. Its layered construction makes it far less likely to warp, swell, or shrink with the temperature and humidity swings we see here in the Bay Area.

Engineered Wood vs. Solid Lumber: A Quick Comparison

To give you a clear picture, let's compare engineered wood with traditional solid lumber. Both have their place on a job site, but knowing their core differences is key to making the right call for your project.

For example, while beautiful solid hardwoods are a classic choice for outdoor projects, engineered products often outperform them for interior structures. You can dive deeper into this by checking out our guide on what is the best hardwood for decking.

Here’s a quick breakdown:

| Attribute | Engineered Wood | Solid Lumber |

|---|---|---|

| Moisture Resistance | Higher and more stable | Susceptible to warping and swelling |

| Dimensional Stability | Excellent; resists twisting and bowing | Varies by species and cut |

| Strength & Consistency | Uniform and predictable strength | Natural variations and knots can occur |

| Design Flexibility | Allows for longer spans and larger sizes | Limited by the size of the tree |

| Sustainability | Uses fast-growing species and wood waste | Sourced from mature, slow-growing trees |

This table shows the choice is about selecting the right material for the right application to ensure performance and longevity.

How Is Engineered Wood Manufactured?

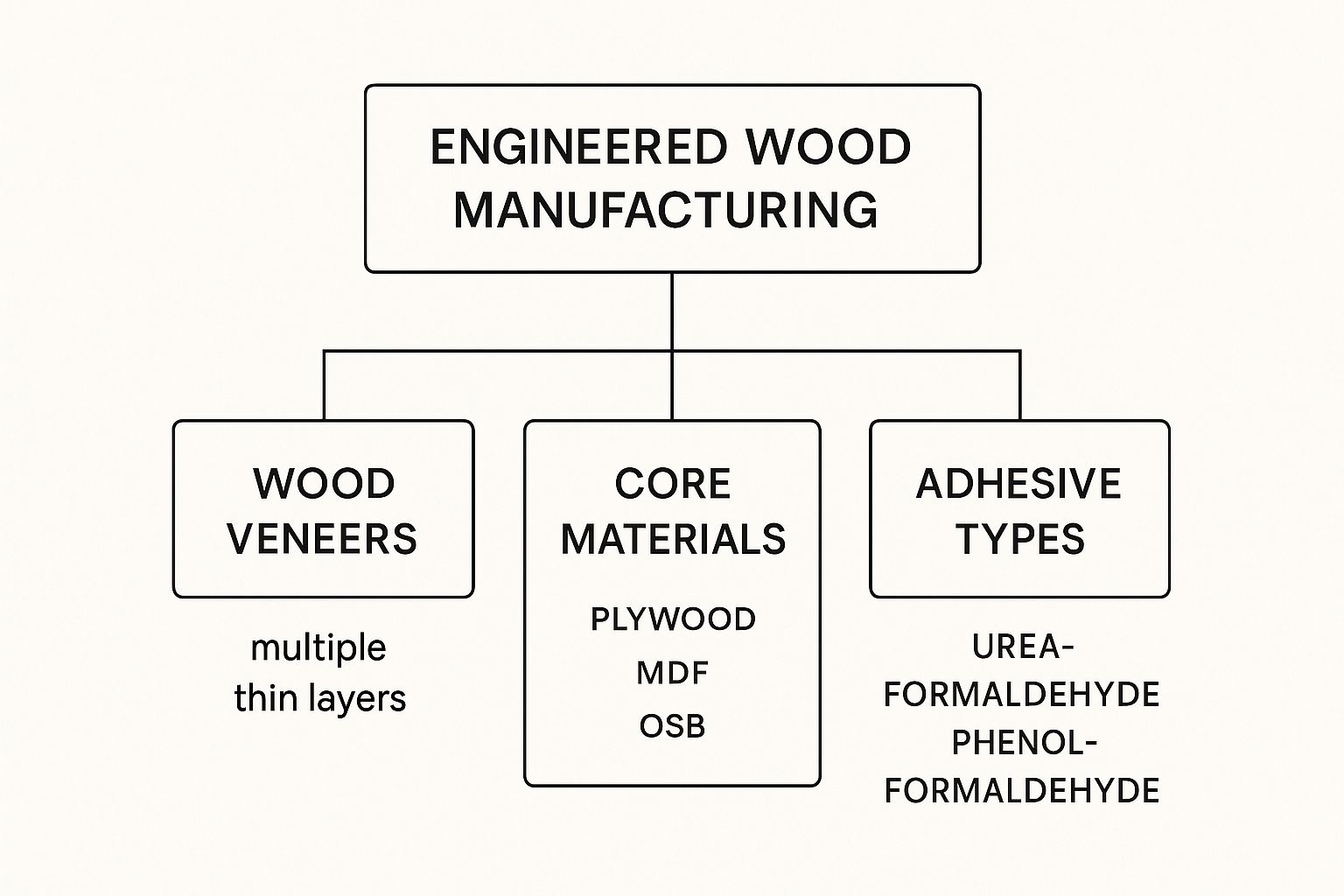

Creating engineered wood is a highly controlled process that transforms raw wood into a high-performance building material. This manufacturing discipline is exactly what gives these materials an edge in Bay Area construction.

The journey starts with responsibly harvested logs, which are broken down into veneers, strands, or fibers. This first step allows manufacturers to remove natural imperfections like knots that you'd find in solid wood.

These wood components are then dried to a precise moisture content to prevent warping. After drying, they’re coated with specialized industrial adhesives formulated for incredible bond strength and moisture resistance.

From Raw Materials to Fused Panels

With the adhesive applied, the real engineering begins. The wood components are arranged in specific patterns designed for maximum strength. In plywood, for instance, veneers are layered with their grains running at right angles to each other, a technique called cross-graining.

The magic happens when immense pressure and heat are applied. The assembled layers are fed into massive hydraulic presses that activate the adhesives, fusing the wood elements into a single, dense, and remarkably stable panel or beam.

This potent combination of heat and pressure creates a product with predictable, consistent performance—a non-negotiable for meeting the Bay Area’s stringent seismic and building codes.

The global engineered wood market is growing fast, which shows how much modern construction relies on these products. Advanced manufacturing ensures every cut is precise, which is why contractors depend on this reliability. To see how we support local builders, read about why Oakland contractors choose Truitt & White in Berkeley.

Common Types of Engineered Wood Products

The term “engineered wood” covers a whole family of products, each designed for a specific job. For any professional in the Bay Area building trade—architects, builders, or remodelers—knowing the difference is key.

Let's break down the go-to products you'll see on job sites from Oakland to San Francisco. We'll look at the most common types and why they’re so well-suited to our region's unique building challenges.

As the diagram shows, performance comes from the specific mix of wood elements and bonding agents used.

Plywood and Oriented Strand Board (OSB)

Plywood is perhaps the most recognized engineered wood. It’s made by layering thin sheets of wood veneer (plies) and turning the grain direction 90 degrees with each layer. That cross-graining gives plywood its incredible strength and stability.

Oriented Strand Board (OSB) is made from rectangular wood strands arranged in cross-oriented layers and bonded with resins. This makes it a tough, cost-effective choice for wall sheathing, roof decking, and subflooring—all critical parts of any Bay Area residential build.

- Bay Area Application: In our damp, coastal climate, specifying moisture-resistant OSB panels for subfloors is a smart move to combat potential swelling from the Bay’s marine layer.

Glued Laminated Timber (Glulam)

When a design calls for long, open spans or soaring, arched ceilings, Glued Laminated Timber (Glulam) is the answer. Glulam beams are built by bonding individual pieces of dimension lumber together. The result is a single, massive structural member that’s stronger than a solid wood beam of the same size.

This blend of strength and design flexibility has made Glulam a favorite among architects for modern Berkeley and Oakland homes.

Laminated Veneer Lumber (LVL) and I-Joists

Laminated Veneer Lumber (LVL) is made by bonding thin wood veneers together with all the grains running in the same parallel direction. This creates an incredibly strong, consistent material that’s perfect for headers, beams, and rim boards.

Working alongside LVL are I-Joists, which are shaped just like the letter "I." They have a vertical web (usually OSB) sandwiched between two horizontal flanges (often LVL).

I-Joists are prized for their exceptional strength-to-weight ratio. They create strong, silent, and perfectly level floors over long spans—a huge advantage for new construction and remodels across the Bay Area.

Cross-Laminated Timber (CLT)

Cross-Laminated Timber (CLT) is one of the most exciting innovations in wood construction. These are massive, solid wood panels made by stacking layers of lumber at 90-degree angles and bonding them together.

CLT is gaining traction in the Bay Area because it's strong, efficient, and has major sustainability points. Because it’s a large-format panel system, it can dramatically speed up construction timelines.

To see the full range of materials we carry, check our inventory of building material supplies in San Francisco. You'll find these products used in everything from kitchen cabinets to building wardrobes.

Key Benefits of Using Engineered Wood in Bay Area Projects

Why are so many Bay Area builders making the switch to engineered wood? It comes down to real-world performance advantages that solve the everyday challenges of building in this unique region.

From standing up to seismic demands to offering a more predictable supply chain, these materials just make sense. They deliver dimensional stability, consistent strength, and a versatility that traditional lumber can't match.

Unmatched Strength and Dimensional Stability

One of the biggest wins with engineered wood is its dimensional stability. The Bay Area's shifting humidity can make solid lumber twist and warp, but engineered products are designed to hold their shape. Their layered construction fights against wood's natural tendency to move.

For contractors in Oakland and Berkeley, that predictability means fewer callbacks. In addition, the manufacturing process removes weak spots like knots, resulting in beams and panels with reliable load-bearing capacities essential for meeting strict seismic codes.

Superior Design Flexibility and Versatility

Engineered wood frees architects and builders from the constraints of conventional lumber. Products like glulam and LVL can be made in much longer lengths and larger sizes than a solid-sawn log. This is how you achieve dramatic open-concept spaces and huge window walls.

- Longer Spans: Create the expansive, open-plan interiors popular in modern Bay Area homes.

- Creative Shapes: Glulam beams can be curved, allowing for unique architectural arches and striking rooflines.

- Consistent Dimensions: The uniformity of products like I-joists ensures floors are level and free of squeaks.

This design freedom empowers you to bring ambitious architectural visions to life while meeting all structural requirements.

Sustainability and Resource Efficiency

Engineered wood is a smart choice for sustainable building. The manufacturing process uses smaller, faster-growing trees and even wood scraps that would otherwise be wasted. This approach aligns with California's Title 24 energy standards and the eco-conscious values of many Bay Area clients.

Incorporating a range of sustainable building materials can elevate a project’s green credentials. To learn more, see our overview of green building at Truitt & White in Berkeley.

Common Applications of Engineered Wood in the Bay Area

Engineered wood is a foundational material in high-performance construction and remodels across the Bay Area. Its versatility lets us solve specific regional challenges while enabling stunning modern designs.

For builders and architects, knowing where to use each type of engineered wood is key to getting the most out of a project.

Structural and Architectural Use Cases

The strength of engineered wood makes it a must-have for a building's structural skeleton, especially with plans for long spans and open layouts.

- Flawless Floors with I-Joists: For an Oakland remodel where perfectly level floors are non-negotiable, I-joists are the go-to.

- Expansive Views with LVL Beams: For a San Francisco home with sweeping bay views, Laminated Veneer Lumber (LVL) provides the tough support needed for headers over wide window openings.

- Dramatic Ceilings with Glulam Beams: The beautiful vaulted ceilings in modern Bay Area homes are often made possible by Glued Laminated Timber (Glulam).

The growth of the engineered wood market is driven by its ability to support complex designs. Its unique mix of durability and sustainability makes it a top choice, as noted in market insights on the rise of engineered wood from IMARC Group.

To help you visualize where these materials fit, here’s a quick application guide.

Engineered Wood Application Cheat Sheet

This table breaks down which products work best for common tasks on a typical Bay Area project.

| Engineered Wood Product | Primary Application | Bay Area Benefit |

|---|---|---|

| I-Joists | Floor and roof joists | Creates flat, stable floors without squeaks; ideal for remodels. |

| LVL | Beams, headers, rim board | Supports long spans over large windows for maximizing views. |

| Glulam | Exposed beams, columns, arches | Allows for dramatic vaulted ceilings and open-concept designs. |

| Plywood | Sheathing, subflooring, gussets | Provides reliable shear strength for seismic resistance. |

| OSB | Wall/roof sheathing, subflooring | Cost-effective sheathing with consistent structural performance. |

| CLT | Walls, floors, roof structures | Prefabricated panels speed up construction schedules significantly. |

This is a simplified overview. Understanding how these products fit into the bigger picture is crucial. To see how engineered wood integrates into larger construction timelines, it can be helpful to review the custom home building process.

Frequently Asked Questions About Engineered Wood

Even with a solid grasp of engineered wood, specific questions often come up. Here are concise answers to the most common queries we get from Bay Area builders, architects, and homeowners.

1. Is engineered wood waterproof?

While many engineered wood products have excellent moisture resistance, they are not completely waterproof. The adhesives create a strong defense against humidity, but they aren't made for prolonged water exposure. For bathrooms or basements, always use products specifically rated for high-moisture environments.

2. How does the cost of engineered wood compare to solid lumber?

The cost varies. Commodity items like OSB are often more budget-friendly than solid lumber, while high-performance products like Glulam beams may have a higher upfront price. However, engineered wood often saves money on labor and reduces waste, improving the overall project value.

3. Is engineered wood a sustainable building material?

Yes, absolutely. The manufacturing process uses smaller, fast-growing trees and wood scraps that would otherwise be wasted. This "whole log" approach makes it a highly sustainable choice that can help projects meet green building standards like LEED.

4. Can I use engineered wood for outdoor projects?

You can, but you must select an exterior-grade product. Standard interior-grade engineered wood will not hold up against the elements. Manufacturers produce specific versions with waterproof adhesives and pressure-treated preservatives for outdoor use on decks or siding.

5. What is the difference between engineered wood and laminate?

Engineered wood has a real wood veneer on top, making it look and feel like solid hardwood. Laminate flooring, on the other hand, is a multi-layer synthetic product with a photographic image of wood grain on its surface. Engineered wood offers greater durability and can often be refinished.

Ready to select the perfect engineered wood for your next project? The experts at Truitt & White are here to help. Our team can guide you through our extensive inventory to find the ideal materials that meet Bay Area building codes and your project’s specific demands. Visit our Berkeley showroom for expert advice.