Installing door casing is the final, crucial step that turns a simple doorway into a finished architectural feature. It's the trim that frames the door and covers the gap between the door frame and the wall. This project requires careful measurements and precise cuts, but it's a skill that professionals and DIY homeowners can master.

This guide provides the essential steps for a perfect installation every time. We'll cover everything from choosing materials to making the final cuts, ensuring a professional result.

Why Flawless Door Casing Installation Matters

Properly installed door casing makes a room feel complete. It's more than just trim; it frames the door and hides the gap between the door jamb and the drywall. For builders and remodelers in the Bay Area, a clean casing installation is a sign of high-quality work.

This guide shares the same methods used by professional carpenters from Berkeley to San Francisco. Whether you are a seasoned contractor or a homeowner taking on a new project, these steps will help you achieve a flawless finish.

The Role of Casing in Design and Function

Door casing serves two important purposes. In terms of design, it helps define a room's architectural style. Functionally, it protects the wall from the bumps and scrapes of daily life.

The global door market was valued at USD 115.53 billion in 2023, showing a strong demand for quality finishes in homes. The right casing enhances both the look and durability of a doorway.

Choosing the right casing profile is just as important as the installation. The style should match the door and your home's architecture, whether it's a modern Oakland loft or a historic Berkeley craftsman.

A new casing can highlight an old door. Consider if your door also needs an upgrade. Our guide on how to choose interior doors can help you find the perfect match for your new trim.

Gathering Your Tools and Materials

Before you begin, gather all the necessary tools and materials. This preparation helps the project run smoothly and avoids trips to the hardware store mid-job. A clean installation starts with being well-prepared.

Your miter saw is the most important tool for this project. A sharp blade is essential for making the clean 45-degree angle cuts needed for professional-looking corners.

Here are the other key tools you will need:

- Tape Measure: For accurate measurements.

- Pencil: To mark your cut lines clearly.

- Brad Nailer: An 18-gauge nailer with 1.5- to 2-inch nails is recommended to secure the casing without splitting the wood.

- Level: A 2-foot or 4-foot level ensures your side casings are perfectly vertical.

Choosing the Right Casing Material

When you visit a Bay Area lumberyard like ours in Berkeley, you'll find several material options for door casing. The best choice depends on your home's style, budget, and desired durability. The trim for a modern Oakland condo will likely differ from that of a historic San Francisco Victorian.

Here is a quick comparison of common casing materials.

Choosing the Right Door Casing Material

This table compares common door casing materials to help you decide on the best option for your project's budget, style, and durability needs.

| Material | Best For | Pros | Cons |

|---|---|---|---|

| MDF (Medium-Density Fiberboard) | Painted trim on a budget; interior applications. | Comes pre-primed, very stable, smooth finish for paint. | Not moisture resistant, can't be stained, less durable than solid wood. |

| Pine | Versatile projects; can be painted or stained. | Affordable, lightweight, easy to work with. | Soft wood that can dent or scratch easily. |

| Oak | High-end projects where staining is preferred. | Extremely durable, beautiful and prominent grain pattern. | More expensive, harder to cut and nail than softer woods. |

Take a look at the other wood types and trim styles in your home. Aim for a cohesive look to make the final result feel intentional and professionally designed.

To learn more about wood options, check out our guide on the types of wood for doors and windows. It provides a detailed comparison to help you choose.

Preparing the Door Frame for a Perfect Fit

The secret to a great casing installation is in the preparation. Before cutting any trim, you must inspect the door jamb and the surrounding wall. This prep work ensures every piece lines up correctly for a professional finish.

If you are replacing old trim, start by carefully removing it. Use a utility knife to score the caulk line where the casing meets the wall. This step prevents paint from peeling and drywall from tearing.

Checking for Plumb and Square

Next, check if your door jamb is straight. Use a level to check the side jambs for plumb (vertical straightness) and the top jamb for level. In older Bay Area homes, walls and frames are often not perfectly square due to settling.

If the frame is significantly out of alignment, it's best to fix it first. Our guide on how to install a door frame can help. A solid frame is the foundation for good trim work.

A common mistake is assuming the door frame is perfect. Always check with a level first. The casing will only look as good as the frame it’s attached to.

Marking the Reveal

Now it's time to mark the reveal. The reveal is a small, consistent setback from the inside edge of the jamb where the casing will sit. This is typically 1/4 inch.

Here’s how to mark it accurately:

- Use a combination square or a tape measure.

- Set your guide to 1/4 inch.

- Rest the tool against the inside of the jamb and draw a light pencil line around the frame—on both sides and across the top.

This line is your guide for placing the casing. It creates a clean shadow line and ensures the trim does not interfere with the door's hinges.

Measuring and Cutting Casing Like a Pro

With the frame prepped and your reveal marked, it's time for the most precise part of the job. Accurate measurements and cuts are what separate a good trim job from a great one.

First, measure for the two vertical side pieces. Measure from the floor to the reveal mark at the top corner of the jamb. Add 1/16 of an inch to this measurement to ensure a tight fit at the top.

Setting Up for Perfect Miter Cuts

Now, move to your miter saw. A sharp blade is essential for clean cuts and tight joints. A dull blade can tear the wood and result in sloppy corners.

Set your miter saw to a 45-degree angle. The top ends of both side casings will be cut at this angle. The bottom of the side casings will usually have a straight 90-degree cut.

Measuring and Cutting the Header Piece

After cutting the side pieces, measure for the header, which is the top horizontal piece. Measure the distance between the inside points of the miter cuts on your side pieces.

Both ends of the header will also be cut at a 45-degree angle, in opposite directions to form the top corners. It's a good practice to cut your pieces a little long. You can then shave off small amounts until you get a perfect fit.

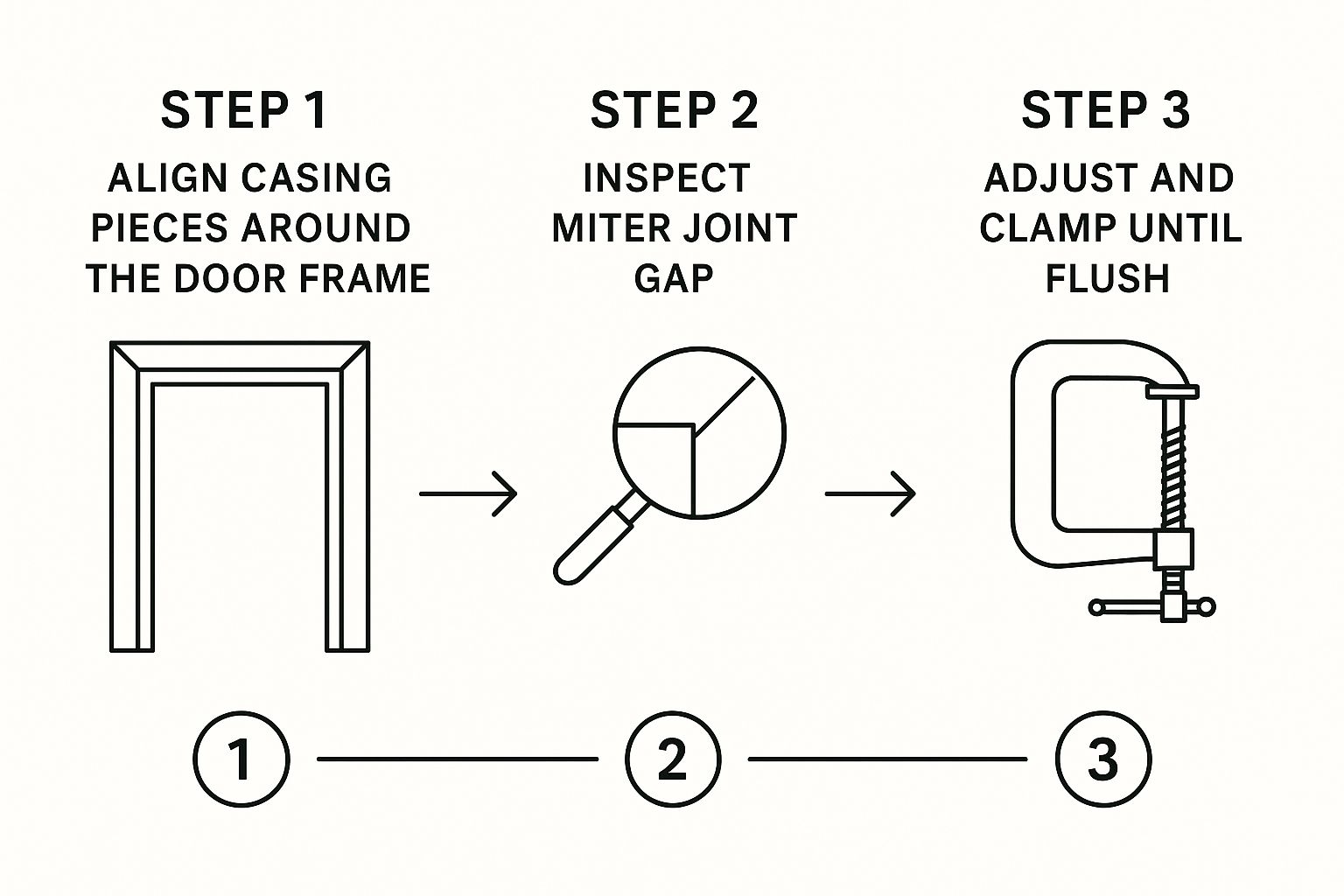

This image shows the dry-fitting process. This step is crucial for checking your cuts before you start nailing.

Pro Tip: Never assume your walls are perfectly square, especially in older Bay Area homes. Always dry-fit the three cut pieces against the door frame. This is your chance to see how the joints line up and make any small adjustments.

The door market was valued at USD 117.76 million in 2024 and is expected to grow, according to a detailed industry analysis. Modern installation techniques often include better sealing to meet California's strict energy codes. This ensures high-performance doors work effectively.

Installing and Finishing for a Flawless Look

With your pieces cut and dry-fitted, you can now install the casing. This final step turns the individual trim pieces into a seamless frame. Careful nailing and finishing will make all the difference.

Use an 18-gauge brad nailer for this job. It provides enough holding power but leaves small nail holes that are easy to fill.

Nailing Your Casing in Place

Start with one of the side casings, aligning it with your reveal mark. Drive nails through the thicker inner edge of the trim into the door jamb, placing them every 12-16 inches.

Next, secure the outer edge by nailing it into the wall studs. Once both side pieces are installed, place the header piece on top. Make sure the mitered corners are tight. A good tip is to shoot a brad nail sideways through the miter joint to pin the two pieces together.

After the casing is nailed in place, step back to inspect it from different angles. This is your last chance to make adjustments before you begin the finishing work.

The Finishing Details That Matter

With the casing installed, the final finishing work begins. First, fill every nail hole with wood putty. Use a putty knife to press it in firmly and let it dry.

Once dry, lightly sand the putty until it is smooth and flush with the wood. Skipping this step will leave visible bumps under the paint. This is also a good time to consider final touches, like new door handles. For inspiration, see our guide on how to choose the correct door hardware for your home.

The final step is to caulk the seams. Apply a thin bead of paintable caulk where the casing meets the wall and the jamb. Smooth the caulk with a wet finger for a clean line that hides any small gaps.

After the caulk has cured, prime the casing and apply two coats of your finish paint. A satin or semi-gloss finish is durable and easy to clean, making it ideal for trim.

Frequently Asked Questions About Installing Door Casing

Here are answers to some of the most common questions about installing door casing. Getting these details right is key to a professional result.

1. What is a "reveal" on a door casing?

A reveal is the small, intentional setback of the casing from the inside edge of the door jamb, usually 1/4 inch. This detail is important because it provides clearance for the door hinges to operate without rubbing against the trim. It also creates a clean shadow line that gives the installation a sharp, professional appearance.

2. Should I use mitered or butted joints for my corners?

The choice depends on the style of your trim. For decorative casing with a detailed profile, 45-degree mitered joints are best because they allow the pattern to flow continuously around the corners. For flat, simple trim, often seen in modern or Craftsman homes in the Bay Area, butted joints are a great option where the header sits flat on top of the side pieces.

3. What is the correct nail size for installing door casing?

For most door casing projects, 18-gauge brad nails that are 1.5 to 2 inches long are the ideal choice. They are strong enough to hold the trim securely but thin enough to prevent splitting the wood. Be sure to nail into both the door jamb and the wall studs behind the drywall for a solid installation.

4. How do I install trim on an uneven or wavy wall?

Uneven walls are common, especially in older homes in Berkeley and Oakland. For small gaps between the casing and the wall, a flexible, paintable caulk works perfectly to create a seamless look. If the gap is very large, you may need to scribe the back of the trim to fit the wall's contour before nailing it.

5. Is it better to paint door casing before or after installation?

For the cleanest finish, it is best to paint the casing before you install it. You can lay the trim flat on sawhorses to apply a smooth coat of primer and paint without worrying about getting paint on the walls. After installation, you only need to fill the nail holes, caulk the seams, and do a quick touch-up.

At Truitt & White, we've been the trusted source for high-quality building materials for contractors and homeowners in the Bay Area for decades. If you’re ready to start your next project, our team is here to help you select the perfect casing and offer the expert advice you need. Visit our Berkeley showroom for expert advice.