When you're planning a deck build, the materials list is crucial. It breaks down into three core areas: the substructure, the surface, and all the finishing components like railings and hardware. Getting this right from the start saves you time and keeps the project on budget.

This guide provides a comprehensive deck building materials list for builders, contractors, and homeowners in the Bay Area. We'll cover everything from the foundation to the finishing touches.

Your Essential Deck Materials Checklist

Starting a deck project in the Bay Area requires careful planning, and a detailed materials list is your most important tool. A well-organized checklist helps create an accurate budget and makes purchasing simple. You'll know every component is accounted for.

The best approach is to organize your materials into logical groups. This simplifies the process and makes it less likely you'll overlook something critical.

Key Material Categories for Your Deck

-

Substructure and Framing: This is the skeleton of your deck. It includes pressure-treated lumber for posts, beams, and joists. You’ll also need concrete for footings and hardware like post bases and joist hangers, ensuring the deck meets strict California building codes.

-

Surface and Decking: This category covers the part of the deck you'll see and walk on. Options range from classic redwood, a favorite in many Berkeley homes, to low-maintenance composite decking that withstands the Bay Area’s climate swings.

-

Railings and Hardware: These parts are about both safety and aesthetics. The list includes railing posts, balusters, and handrails, plus all the necessary fasteners. You'll also need specialized screws and bolts to assemble the structure securely.

For a deeper dive, explore our complete deck planning guide and materials overview for more detailed information.

Quick Reference Deck Materials Checklist

Here's a quick table that summarizes the essential categories. It’s a great starting point for building your own detailed list.

| Category | Key Materials | Primary Function |

|---|---|---|

| Foundation & Substructure | Concrete Mix, Post Anchors, Posts, Beams, Joists | Provides a stable base and the primary structural framework. |

| Deck Surface | Decking Boards (Wood or Composite), Hidden Fasteners or Screws | Creates the walking surface and defines the deck's appearance. |

| Railing System | Rail Posts, Top & Bottom Rails, Balusters, Post Caps | Ensures safety around the perimeter and adds a finished look. |

| Hardware & Fasteners | Joist Hangers, Structural Screws, Bolts, Ledger Board Screws | Secures all structural components together for a rigid, safe build. |

| Finishing Touches | Stairs (Stringers, Treads, Risers), Flashing, Stain or Sealer | Adds accessibility, protects the house from water, and preserves the wood. |

Breaking your project into these chunks is key to a smooth build. It turns an overwhelming task into a straightforward process.

Building a Strong Deck Substructure

A deck is only as good as its foundation. The safety and longevity of your project depend on a solid substructure. This hidden framework does all the heavy lifting, so choosing the right materials is required for a safe, code-compliant build in the Bay Area.

A rock-solid frame begins with the right lumber. For any wood near or touching the ground—posts, beams, and joists—pressure-treated lumber is essential. It's chemically treated to fend off moisture, rot, and termites, which are common issues in our local climate.

Framing and Foundation Essentials

A sturdy substructure is built from a few key components working together. Each has a critical job in distributing weight and keeping the deck stable. Your foundational deck building materials list must include these items.

- Concrete Mix: This creates solid footings that anchor your support posts. Ensure the mix is rated for structural use.

- Pressure-Treated Posts: These are the vertical legs of your deck, transferring the load to the footings. Most projects use 4×4 or 6×6 posts, depending on the deck's height.

- Pressure-Treated Beams and Joists: Beams sit across the posts, and joists attach to the beams, forming the grid for your decking.

Essential Metal Connectors

In California, building codes are clear about how a deck frame must be assembled. Metal connectors are mandatory for creating strong joints that can handle seismic activity. These are required for structural integrity.

According to local building codes, connections between posts, beams, and joists must be reinforced with approved metal hardware. This ensures a safe and durable deck structure.

These small but mighty pieces of hardware hold your deck's skeleton together. Make sure your plans include galvanized post bases, joist hangers, and the right structural screws. Our team at Truitt & White knows these codes and can help you select the right Simpson Strong-Tie products for your project.

Choosing Your Decking Surface Material

The decking surface sets the entire look and feel of your outdoor space. Here in the Bay Area, we must consider how materials will hold up to intense sun in Oakland or coastal moisture in San Francisco.

Your choice will balance aesthetics, budget, and maintenance. Natural wood offers timeless beauty, while modern composites provide incredible durability with little upkeep.

Natural Wood Decking Options

For many homeowners in Berkeley and the surrounding area, nothing beats the classic feel of real wood. Local favorites like Redwood and Cedar are solid choices due to their natural resistance to rot and insects. Understanding the basic differences between softwood and hardwood helps in making an informed decision.

We've created a guide on finding the best hardwood for decking to help you explore wood types suited to our climate. Remember, wood needs annual cleaning and sealing to keep it looking great.

Composite Decking: A Low-Maintenance Alternative

Composite decking has become a popular choice for a reason. Made from wood fibers and recycled plastic, it's built to last. It resists fading, staining, and moisture without the yearly sealing that wood requires.

The global composite decking market is projected to grow by $3.99 billion between 2025 and 2029. This reflects a consumer shift toward low-maintenance outdoor solutions. Learn more about the growth of composite decking at PR Newswire.

For homeowners wanting a beautiful deck without constant upkeep, composite is a fantastic investment.

Wood vs. Composite Decking Comparison

To help you decide, here is a breakdown of the key differences between wood and composite decking. This guide can help you weigh the pros and cons for your project.

| Feature | Natural Wood (Redwood/Cedar) | Composite Decking |

|---|---|---|

| Upfront Cost | Generally lower initial cost. | Higher initial investment. |

| Maintenance | Requires annual cleaning, staining, or sealing. | Low maintenance; occasional cleaning with soap and water. |

| Lifespan | 15-25 years with proper maintenance. | 25-30+ years, often with a manufacturer warranty. |

| Aesthetics | Authentic, natural look. Color can weather over time. | Consistent color and texture. Wide range of styles available. |

| Durability | Prone to rot and splinters if not maintained. | Resistant to rot, insects, fading, and staining. No splinters. |

The choice comes down to personal preference and long-term planning. If you love the natural aging of wood, it's a wonderful choice. If you prefer a set-it-and-forget-it solution, composite is tough to beat.

Selecting Railing Systems and Hardware

Your deck railing is a key safety requirement and a major design feature. Choosing the right system from your deck building materials list is important, especially when preserving a view of the Berkeley Hills or San Francisco Bay.

Any railing system must meet California's strict building codes. These rules dictate a minimum height of 36 inches for residential decks and baluster spacing that prevents a 4-inch sphere from passing through.

Common Railing Material Options

Picking a railing material is a balance of style, maintenance, and budget. Each option offers perks that work well for Bay Area homes.

- Wood Railings: Classic wood railings, like redwood or cedar, offer a timeless look. They are highly customizable but require regular maintenance.

- Metal Railings: For a modern look, aluminum or powder-coated steel systems are a great choice. They are durable, require little upkeep, and offer clean lines.

- Cable Railings: When the view is the priority, cable railing is tough to beat. The thin steel cables create an almost invisible barrier, providing unobstructed sightlines.

- Composite Railings: Pairing composite decking with a matching railing system creates a seamless, low-maintenance design. These systems resist fading and moisture damage.

The best railing system balances code compliance, durability, and style. Our team at Truitt & White can help you find the perfect fit for your project.

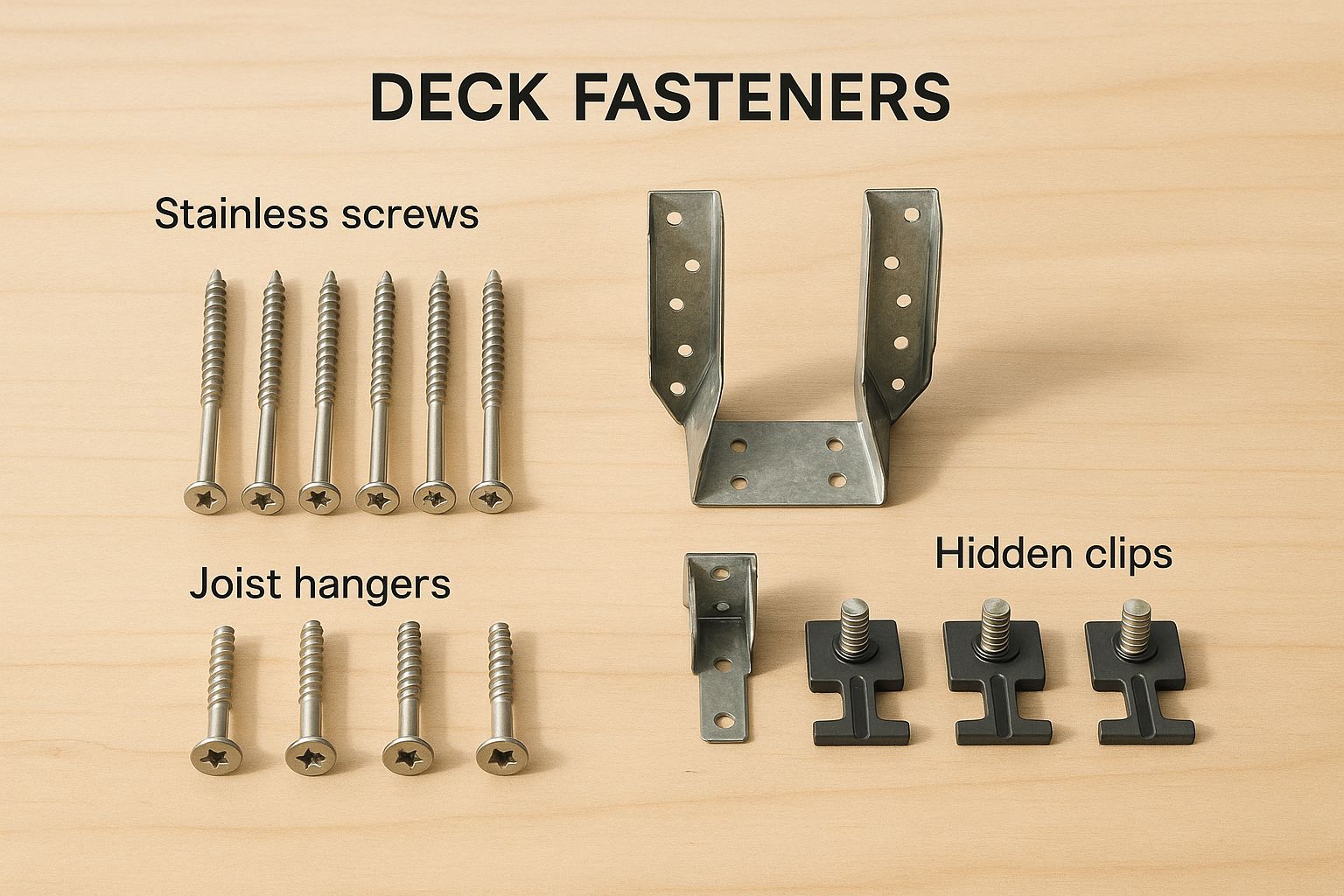

Using the Right Fasteners for Your Deck

When putting together a deck building materials list, the hardware is as critical as the lumber. Fasteners guarantee the deck's structural integrity and give it a clean, professional finish. Choosing the right screws, bolts, and connectors is essential for a safe, long-lasting deck.

The fastener you need depends on the material and its location. For the substructure, heavy-duty structural screws and galvanized bolts are non-negotiable. They are engineered to handle heavy loads and resist wear.

Choosing Corrosion-Resistant Screws

Living in the Bay Area means dealing with a coastal climate, making corrosion resistance a huge deal. Moisture and salt can eat away at the wrong metal, compromising your deck’s safety.

- Coated Screws: These are a cost-effective option for pressure-treated lumber. The coating acts as a barrier against chemicals and the elements.

- Stainless Steel Screws: If building near the coast or using hardwood like Ipe, stainless steel is the way to go. It offers the best protection against rust and staining.

Hidden Fastening Systems

For a modern, seamless look, hidden fasteners are a top choice. These systems use clips that fit into grooved-edge boards, securing them from the side.

The result is a beautiful surface with no visible screw heads. Eliminating screw holes also removes entry points for water, helping the deck last longer. For more on hardware, learn how Simpson Strong-Tie products help build stronger decks.

Adding Finishing Touches to Your Deck

The final details transform a standard deck into a polished outdoor living space. These finishing touches in your deck building materials list are key to a professional look. They add function and style, making the deck an extension of your home.

Key components like fascia boards are a must for a clean look. These thin boards cover the rim joists, hiding the ends of your substructure. Similarly, stairs rely on sturdy treads and risers for safety and visual appeal. For more ideas, our complete deck guide is a great resource.

Custom Features and Protection

Custom add-ons can elevate your deck. Built-in benches and planter boxes are popular choices in Berkeley and Oakland, adding seating and greenery.

Another critical element is a high-quality waterproofing membrane. This protects joists from moisture damage, extending the life of the structure. According to industry reports, homeowners are increasingly investing in functional outdoor spaces, driving market growth. You can read more about strategic insights in the decks market.

Frequently Asked Questions

What’s the Best Low-Maintenance Decking for the Bay Area?

Composite and PVC decking are the top choices for a low-maintenance deck in the Bay Area climate. These materials are engineered to resist moisture, sun, and pests, requiring only occasional cleaning. This is a significant advantage over wood decks, which need annual staining or sealing.

Do I Need a Building Permit for a Deck in Berkeley?

Yes, you will likely need a building permit for any deck that is more than 30 inches off the ground or attached to your house. Always check with the City of Berkeley's building department before starting your project. This ensures your deck meets all local safety and building codes.

What Kind of Lumber Should I Use for a Deck Frame?

You must use pressure-treated lumber rated for ground contact for your deck's substructure (posts, joists, and beams). This treatment protects the wood from moisture, rot, and insects. It is essential for ensuring your deck's foundation remains solid for years to come.

Should I Choose Redwood or Composite Decking?

This choice depends on your priorities. If you love the natural beauty of real wood and are prepared for regular upkeep, redwood is a fantastic option. However, if you value durability and minimal maintenance, composite decking is the better choice.

What Are Hidden Deck Fasteners?

Hidden fasteners are a system of clips or screws installed from the side or underneath deck boards. They create a clean, smooth surface with no visible screw heads. This method is popular for composite decking and achieves a sleek, high-end finish.

Planning a deck project requires expertise and the right advice. The team at Truitt & White has been a trusted partner for Bay Area builders, contractors, and homeowners for decades. Visit our Berkeley showroom or connect with us online for personalized guidance on your deck building materials list.