The cost of Parallam beams typically ranges from $15 to $40 per linear foot for the material itself. This price depends heavily on the beam's size and grade.

While this is a higher upfront investment than traditional lumber, the price reflects its superior engineered strength. Parallam is a reliable choice for demanding structural projects in the Bay Area.

Understanding Parallam Beam Material Costs

When you look at the price of Parallam, you are investing in a high-performance building material. Unlike standard sawn lumber, Parallam Parallel Strand Lumber (PSL) is an engineered wood product. This process gives it incredible, consistent strength.

Because of its strength, Parallam is a go-to choice for builders and architects across the Bay Area. It is ideal for long spans where structural integrity cannot be compromised. You can learn more about what engineered wood is and how it shapes modern construction.

A Quick Look at Material Costs

The price per linear foot is directly tied to the beam's dimensions. A larger, deeper beam that carries a heavier load will cost more. This is because it requires more raw materials and a more involved manufacturing process.

Here is a quick breakdown to help you budget for your next project in Berkeley or Oakland. Remember, these are estimates. A final quote will depend on your exact project specifications.

Key Insight: While Parallam's material cost is higher than standard dimensional lumber, its impressive strength-to-weight ratio often means you can use a smaller beam or achieve a longer span, which can positively influence overall project design and costs.

Estimated Parallam Beam Material Cost by Size

| Beam Size (Width x Depth) | Estimated Cost per Linear Foot |

|---|---|

| 3.5" x 9.5" | $15 – $22 |

| 5.25" x 11.875" | $20 – $30 |

| 7" x 14" | $30 – $40+ |

These prices provide a solid baseline for your budget. The real value comes from Parallam's long-term performance and the time you'll save on labor.

What Factors Drive the Final Parallam Price?

While a simple price per linear foot gives you a ballpark number, several key factors shape the final cost of your Parallam beams. Understanding these variables is essential for creating accurate bids in the Bay Area.

The most obvious cost driver is the beam's physical size. A longer, wider, or deeper beam requires more raw material and a more complex manufacturing process, which increases the price.

Beam Dimensions and Grade

A Parallam beam's depth, width, and length are the biggest pieces of the cost puzzle. Engineers specify these sizes based on the load the beam must support and the distance it needs to span.

The beam's grade also plays a major role. Different grades are engineered for different levels of strength. A higher-grade beam built for a heavy-duty structural job will carry a higher price tag.

- Depth and Width: These two have the biggest impact. Increasing a beam's depth by a few inches can dramatically increase both its load-bearing capacity and its cost.

- Length: Parallam can be made in lengths up to 60 feet. Longer beams are more expensive to produce, ship, and handle on the job site.

- Grade: The structural performance you need dictates the grade. For example, a beam with a 2.0E rating is significantly stronger—and pricier—than one rated at 1.8E.

Wood Species and Market Conditions

Parallam is generally made from Douglas Fir or Southern Yellow Pine. Here in the Bay Area, Douglas Fir is the preferred species due to its exceptional strength-to-weight ratio. This makes it a perfect fit for our projects, where seismic performance is a key consideration.

The cost of raw materials can change. Recent supply chain issues have caused timber prices to fluctuate, sometimes adding 5-15% to project costs according to some industry reports on Parallel Strand Lumber. If you're interested in sustainable building options, we cover more in our guide to eco-friendly construction materials.

Builder's Tip: Always check with your supplier for current pricing when creating a bid. Local demand in hot markets like San Francisco and Oakland can affect availability and lead times, impacting your project schedule and budget.

Comparing Parallam Costs With Other Beam Options

The cost of Parallam beams should be compared with other common structural choices. A smart decision balances the upfront material cost with long-term performance and on-site labor savings.

Parallam PSL is a premium product. It often carries a higher price per linear foot than Laminated Veneer Lumber (LVL) or traditional solid timber. However, its strength-to-weight ratio means you can often use a smaller beam for the same span, which can level the playing field on price.

Performance and Price: A Head-to-Head Look

Traditional lumber must be sorted to find pieces without knots, twists, or crowns. Parallam eliminates this step because it is perfectly straight and dimensionally stable every time.

This consistency means faster installations and lower labor bills, which is critical in markets like San Francisco and Berkeley.

Glulam (Glued Laminated Timber) is another popular option, especially for its appearance in exposed applications. While its cost is similar to Parallam, Parallam usually has a higher bending strength. This allows it to handle heavier loads over longer distances. Understanding different framing lumber grades is key to picking the right option.

Parallam vs. Other Beams: Cost and Performance Comparison

The table below breaks down the key differences to help you decide which beam is the right fit for your budget and project.

| Beam Type | Avg. Material Cost (per linear foot) | Relative Strength | Common Bay Area Uses | Installation Notes |

|---|---|---|---|---|

| Parallam (PSL) | $15 – $40 | Highest | Long-span headers, primary carrying beams, ridges | Very uniform, reducing on-site labor and adjustments. |

| Glulam | $14 – $35 | High | Exposed architectural beams, arches, residential headers | Aesthetically pleasing for visible applications. |

| LVL | $10 – $25 | Medium-High | Floor joists, headers, rim board | Cost-effective and versatile for standard spans. |

| Solid Sawn Timber | $5 – $15 | Varies | Traditional framing, short spans | Less consistent; requires sorting for crowns and defects. |

The "best" beam depends on engineering needs, aesthetics, and your total installed budget. While Parallam might have a higher material cost, its superior strength and labor-saving consistency often make it the most reliable choice for tough structural jobs.

Calculating Your Total Installed Cost

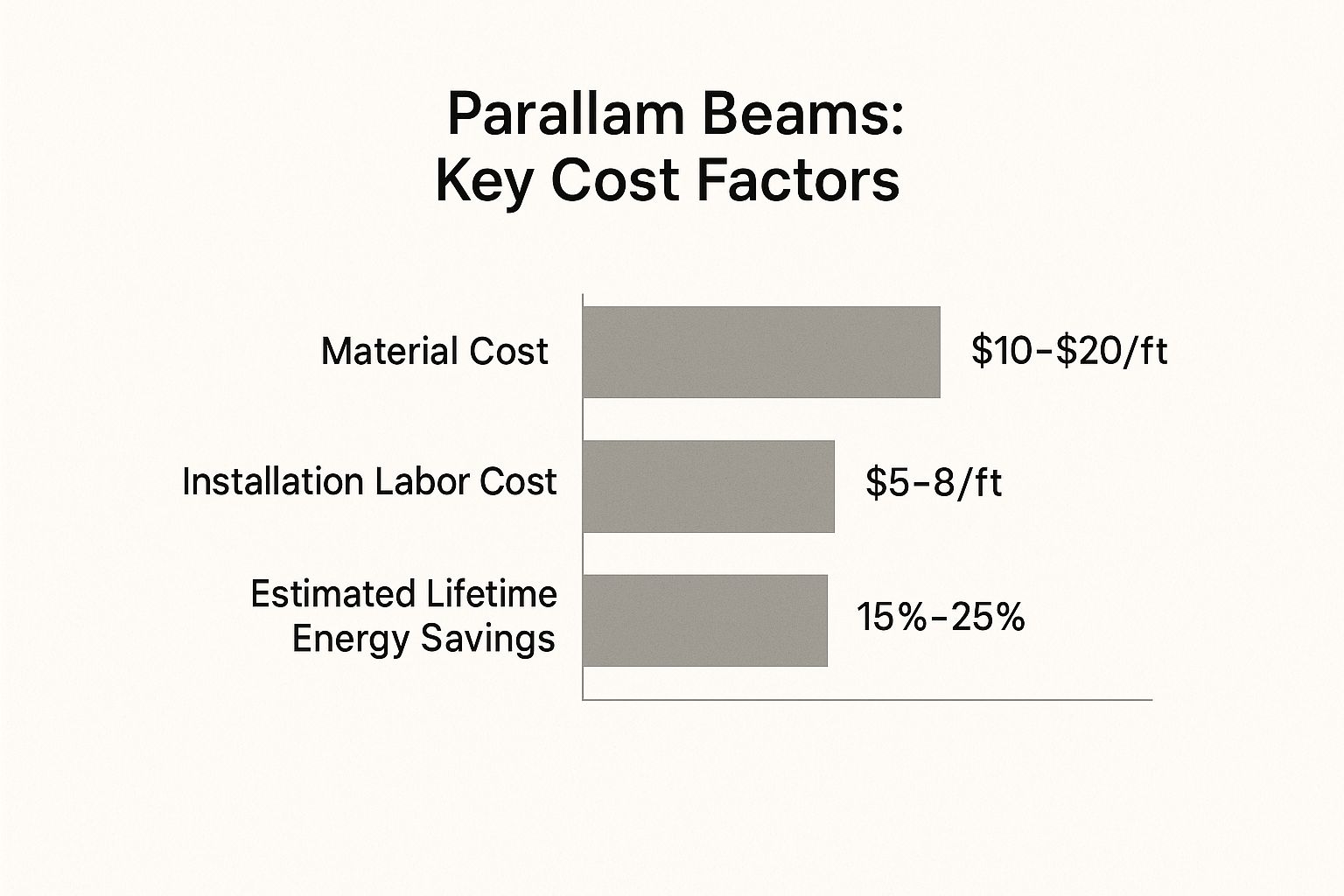

An experienced builder knows the material price is only the beginning. To truly understand the cost of Parallam beams, you need to look at the total installed cost. This includes your crew's time and the equipment needed to lift the beam into place.

Looking at the full picture often shows that Parallam can be a cost-effective choice. Its engineered consistency can cut down other expenses, saving you money in the long run.

Beyond the Material: A Breakdown of Costs

The total installed cost is the sum of every expense to get the beam properly placed. In high-labor markets like San Francisco and Berkeley, these related costs can add up quickly.

Here are the key factors to include in your budget:

- Specialized Labor: Parallam's weight and size often demand an experienced crew for safe and efficient installation.

- Equipment Rental: For longer or heavier beams, you may need to rent a crane or forklift. Rental fees and operator costs add to your budget.

- Engineering Consultations: If you face complex situations or need on-site changes, another consultation with a structural engineer may be necessary.

How Parallam Can Lower Installation Expenses

Parallam beams are manufactured to be perfectly straight and dimensionally stable. You will not find warps, twists, or crowns. This precision saves your crew hours they might otherwise spend sorting and shimming warped lumber.

For builders in the Bay Area, where every hour on the job site is money, this is a game-changer. Fewer on-site modifications mean faster installations, fewer callbacks, and a more predictable construction schedule.

That efficiency is vital for a project's financial health. For more strategies on keeping your numbers in line, check our insights on effective construction budget management.

Thinking Long-Term: The Real Value of Parallam

It’s easy to focus on the upfront cost and wonder if Parallam is worth it. But the real answer is about total lifecycle value. For builders and homeowners in the Bay Area, investing in structural integrity from day one prevents expensive problems later.

Parallam’s true worth appears over the life of the building. It resists warping, shrinking, and splitting better than traditional lumber. This stability means fewer callbacks for issues like drywall cracks or uneven floors, protecting your budget and reputation.

Durability That Drives Down Lifetime Costs

Parallam's ability to hold its shape and maintain its strength reduces long-term maintenance. This is a huge benefit in the Bay Area, where our microclimates put constant stress on building materials.

Key Takeaway: The higher initial cost of Parallam beams is a strategic investment. It provides peace of mind, structural predictability, and a lower total cost of ownership by minimizing future repairs.

This isn't just a theory. For example, studies on how Parallam PSL performs in harsh conditions like bridge decks show its incredible resistance to bending and environmental aging. Researchers concluded that life-cycle savings from reduced maintenance justified the premium cost.

A Smarter Conversation with Your Clients

When you frame the material choice around long-term value, you help clients see beyond the initial quote. Explaining this investment ensures a stronger, more stable home for decades.

- Fewer Call-Backs: A stable structure means less settling, reducing the need for post-construction fixes.

- Enhanced Safety: In a seismically active region like ours, strong, predictable materials add an invaluable layer of resilience.

- Lasting Performance: Parallam's consistency ensures the building performs as designed for its entire lifespan.

Positioning the higher upfront cost as a smart decision for the home's structural integrity helps clients understand they are paying for lasting quality.

How to Source Parallam Beams in the Bay Area

When you’re ready to buy Parallam beams, partner with a local supplier who knows the Bay Area. A team with experience understands local building codes in places like Berkeley and Oakland. This ensures every piece of lumber you get is compliant and ready for inspection.

A good supplier is more than just an order-taker; they are a key part of your team. They can offer advice on product selection and deliver accurate estimates tailored to your plans. The global market for Parallel Strand Lumber is expected to grow, as seen in market reports on this market growth on Dataintelo, making a reliable local source essential.

For builders and contractors, a trusted lumberyard is a strategic asset. Their expertise saves time, prevents costly errors, and keeps your project on schedule.

To ensure you're getting the right product, see our guide on selecting quality lumber in the East Bay. Ready to move forward? Connect with the experts at Truitt & White to discuss your project and get a precise quote today.

Frequently Asked Questions About Parallam Beams

Here are some common questions we hear from builders, architects, and homeowners in the Bay Area.

1. Is Parallam more expensive than steel I-beams?

The material cost for Parallam is often similar to or slightly less than steel I-beams. The real savings come during installation. Parallam is lighter and can be worked with standard tools, while steel requires welders and specialized equipment, making Parallam a more economical choice overall.

2. Can I use Parallam beams for an outdoor deck in the Bay Area?

No, standard Parallam PSL is for interior use only. For outdoor projects like decks or pergolas, you must use a pressure-treated version called Parallam Plus PSL. Using the wrong product in the Bay Area's damp climate can lead to structural failure.

3. Why is Parallam so much more expensive than regular lumber?

Parallam's higher cost comes from its advanced manufacturing process. It's an engineered product made from wood strands bonded with adhesive under heat and pressure. This process removes natural defects, creating a beam that is much stronger and more consistent than standard lumber.

4. How do I get an accurate quote for my project?

To get an accurate price, bring your architectural or engineering plans to a knowledgeable building material supplier. The plans contain the exact dimensions, grade, and length needed for each beam. A local Berkeley or Oakland supplier can then provide a project-specific quote based on current market conditions.

5. Does the Bay Area's seismic activity affect my choice of beam?

Yes, absolutely. Building in a seismic zone like the Bay Area makes every structural choice critical. Engineered wood products like Parallam offer high strength and stability, which helps create building systems that are more resilient during an earthquake. Always ensure your project's engineering complies with local seismic codes.

At Truitt & White, our team has helped Bay Area builders select the right structural materials for decades. We provide accurate quotes and reliable advice to start your build on the right foot. Connect with us to discuss your project today.