When budgeting for a new floor system, the first number you need is the material cost. For TJI joists, you can expect prices from $4.00 to over $8.00 per linear foot. This is your starting point, whether you're framing a new floor in Berkeley or remodeling in Oakland.

Of course, that price depends on the joist's depth, its performance series, and your supplier.

Understanding TJI Joist Costs

Planning a construction project in the Bay Area means getting a firm handle on material costs. Engineered wood I-joists, like the TJI series from Weyerhaeuser, are a high-performance alternative to traditional lumber. Their price can vary based on several factors.

Think of them like car tires. While they all do the same basic job, some are engineered for higher performance. That capability is reflected in the price tag.

This guide gives builders, contractors, and homeowners a clear breakdown of TJI joist pricing. We'll start with baseline material costs and then explore other factors that shape your final investment.

What Determines the Initial Price?

The main factors driving the per-foot cost are the joist's physical specifications. Deeper joists or those from a higher-performance series are built to handle greater loads. That advanced engineering costs more to produce.

Here are the key elements that set the initial price:

- Joist Depth: A deeper joist (like 14" versus 9.5") is stronger and will cost more per foot.

- Joist Series: Manufacturers offer different series, such as the Trus Joist TJI 110, 210, or 560. Each series has unique load-bearing capacities for specific applications.

- Supplier and Location: Prices fluctuate between lumberyards. Sourcing from a local supplier like Truitt & White ensures you get competitive pricing relevant to the Bay Area market.

Once you understand these basics, you can create a solid material estimate.

Estimated TJI Joist Cost Per Linear Foot

This table offers a quick reference for the estimated cost of common TJI joist sizes. Prices are approximate and vary by supplier and Bay Area location.

| TJI Joist Series/Depth | Typical Price Range (Per Linear Foot) | Common Application |

|---|---|---|

| TJI 110 / 9.5" | $4.00 – $5.50 | Residential floors with standard spacing and moderate spans. |

| TJI 210 / 11 7/8" | $5.25 – $6.75 | A versatile choice for residential floors, offering longer spans than the 110 series. |

| TJI 360 / 14" | $6.50 – $8.00 | High-performance residential floors, accommodating longer spans and heavier loads. |

| TJI 560 / 16" | $8.00+ | Demanding applications like commercial floors or complex residential designs. |

Remember, these figures are a benchmark. Your final cost will depend on your supplier and project's engineering requirements.

Key Factors That Influence TJI Joist Pricing

A ballpark price for TJI joists is a good start, but your final invoice will depend on project details. Two identical-looking floor plans in Berkeley could have different costs based on engineering specs. The structure's design and load requirements truly drive the price.

Think of it like choosing a delivery truck. A small van for local packages costs less than a semi-truck built for heavy freight. The "freight" your floor must carry determines which joist you need and how much you'll pay.

Joist Depth and Series Selection

Not all TJI joists are the same. Weyerhaeuser makes several series (like TJI 110, 210, or 560) with different depths and flange widths. A deeper joist, like a 14-inch model, is stronger than a 9.5-inch one and costs more per foot.

However, a deeper joist might save you money in the long run. Its strength allows for wider spacing between joists, meaning you buy fewer of them. This is a crucial calculation for any contractor managing a budget.

This chart from Weyerhaeuser shows the different series and their applications. It helps visualize how performance needs influence product choice.

As you can see, higher series numbers like the TJI 560 are engineered for demanding spans in commercial buildings or custom homes.

Span Length and Load Requirements

The next major factor is the combination of span and load. A longer span or a heavier load—like a San Francisco kitchen with stone countertops—demands a more robust joist. California building codes are specific about these requirements to ensure safety, especially with seismic activity in mind.

An engineered design will specify the exact TJI series, depth, and spacing needed to meet these codes. This removes guesswork and ensures structural integrity, but it also directly impacts your material costs.

Market Demand and Supply Chain Logistics

You can't ignore broader economic factors. The global I-joist market was valued at around $2.6 billion in 2024 and is projected to grow. This rising demand can affect pricing and availability, making efficient construction supply chain management more important than ever for Bay Area builders.

Several things can impact supply and your final cost:

- Raw Material Costs: Fluctuations in wood and adhesive prices affect manufacturing costs.

- Shipping and Freight: Fuel prices and logistical challenges in the Bay Area can add to the final bill.

- Supplier Inventory: Local availability at lumberyards like Truitt & White can influence pricing.

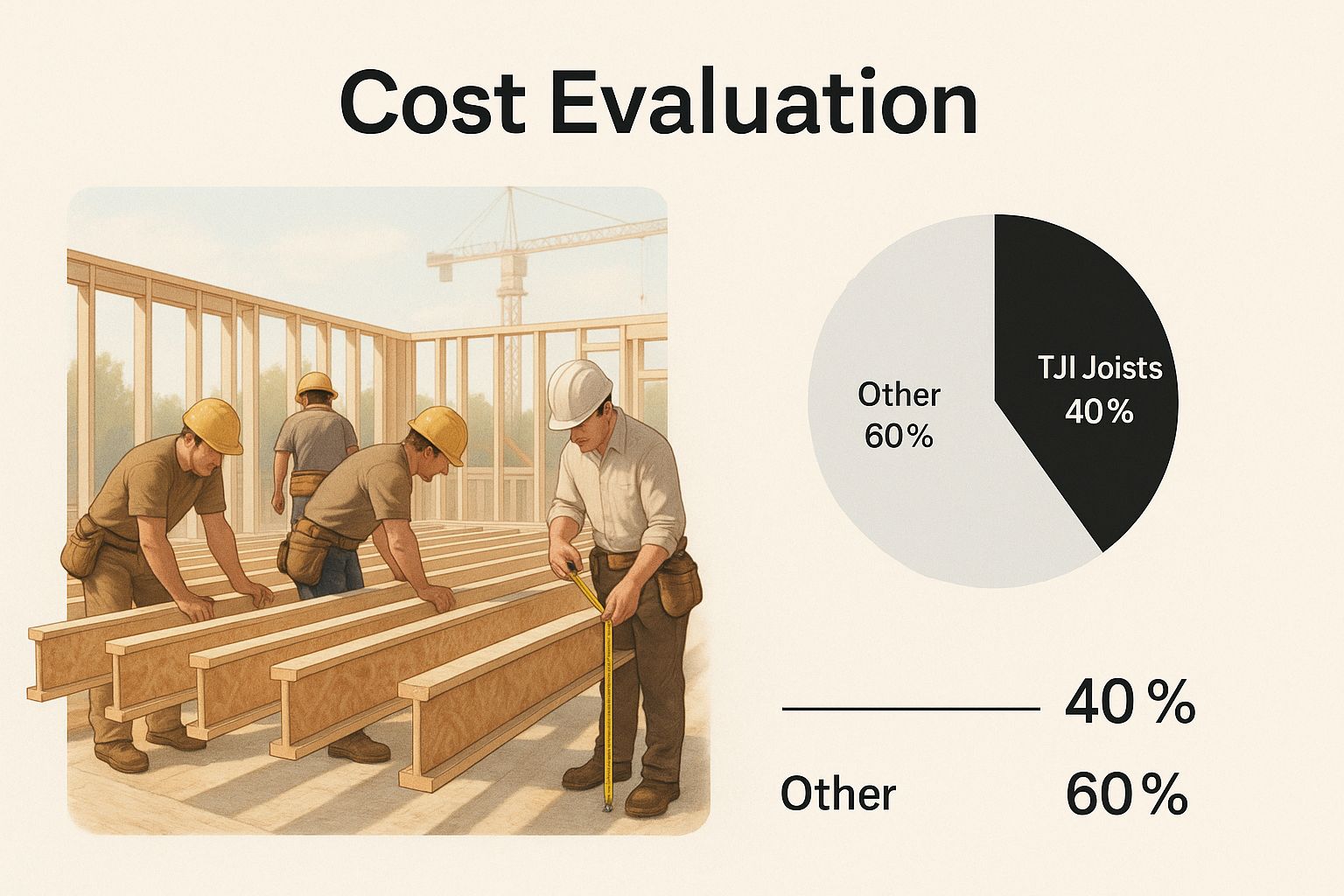

Comparing TJI Joists to Other Flooring Systems

To understand the value of TJI joists, it helps to compare them with alternatives. In any Bay Area construction project, picking a floor system is a balance of cost, performance, and installation ease. TJI joists, dimensional lumber, and open-web floor trusses each offer something different.

A closer look helps builders in places like Berkeley and Oakland make smart decisions. While traditional lumber may seem cheaper upfront, its natural flaws can increase labor costs. TJI joists are engineered for precision, allowing for long, clean spans that speed up framing time.

This image shows a crew on-site with TJI joists, highlighting that cost-effectiveness is about more than the material's price tag.

You have to look at the whole system—labor, joist spacing, and long-term performance—to see where the real value lies.

TJI Joists vs. Dimensional Lumber

The classic comparison is between engineered I-joists and traditional lumber, like 2x10s or 2x12s. Dimensional lumber usually has a lower price per linear foot. The catch is that warping, crowning, and shrinking can lead to uneven floors and more on-site fixes.

TJI joists are manufactured to be perfectly straight and stable every time. This consistency means a faster installation and a quieter, more solid floor. For the open-concept homes popular in the Bay Area, TJI joists are often the only way to achieve long spans without extra support beams. You can learn about other high-performance materials in our deck planning guide.

TJI Joists vs. Open-Web Floor Trusses

Open-web floor trusses are another engineered option. Their open design makes it easy to run pipes, wires, and HVAC lines. The trade-off is that they are typically custom-ordered and can be heavier to handle on a job site than TJI joists.

Weyerhaeuser often argues that I-joists offer better all-around value than trusses. Their philosophy is simple: "deeper is cheaper." This means using a slightly deeper TJI joist allows a builder to increase the spacing between joists. You use less material overall, which lowers total cost without sacrificing performance.

A Quick Comparison: Floor Framing Options

Choosing a floor system depends on your build's specific needs. This includes span requirements, MEP integration, budget, and timeline. Here’s a head-to-head comparison to help you weigh the pros and cons for your next Bay Area project.

| Feature | TJI Joists | Dimensional Lumber | Open-Web Floor Trusses |

|---|---|---|---|

| Material Cost | Moderate; higher per foot than lumber but often cheaper overall system. | Low; typically the least expensive option per linear foot. | High; often the most expensive option, usually custom fabricated. |

| Span Capability | Excellent; engineered for long, unsupported spans. | Limited; requires more intermediate supports for longer spans. | Excellent; can span very long distances, ideal for open designs. |

| Consistency | Very High; factory-made for straightness and stability. | Low; prone to natural defects like warping, crowning, and twisting. | High; engineered product with consistent dimensions and performance. |

| Installation Speed | Fast; lightweight and consistent, speeding up framing. | Moderate; requires sorting and shimming, which can slow down the process. | Slow; can be heavy and cumbersome, often requiring a crane for placement. |

| MEP Integration | Good; holes can be cut in the web according to manufacturer specs. | Poor; requires drilling through solid wood, which can compromise strength. | Excellent; open-web design makes running utilities incredibly easy. |

| Best For | Open-concept homes, projects needing quiet/stiff floors, long spans. | Traditional construction, projects with shorter spans, tight budgets. | Complex commercial projects, custom homes with extensive HVAC/plumbing. |

TJI joists hit a sweet spot for many modern projects. They offer a fantastic blend of performance, cost-effectiveness, and ease of use.

Calculating Your Installation and Labor Costs

Material price is only half the story. To figure out the true cost of using TJI joists, you have to look at labor. This is a huge part of any construction budget, and it's where engineered wood products really shine.

For any builder in Berkeley or homeowner in Oakland, understanding how installation impacts your bottom line is key.

TJI joists are engineered to be lightweight and easy to handle, which saves on labor. A single worker can often carry a TJI joist, which might take two people with traditional lumber. That efficiency makes the framing process faster and cuts down on crew hours.

Why Efficient Installation Matters

A faster floor system installation directly affects your project's timeline and profitability. When a framing crew can lay a floor quickly, plumbers and electricians can start their work sooner. For any contractor managing a tight schedule in the Bay Area, that streamlined workflow is a massive advantage.

Here’s how TJI joists help keep labor costs down:

- Reduced Handling Time: Being light means less crew fatigue and quicker placement.

- Longer Spans: TJI joists can span longer distances, often requiring fewer intermediate supports.

- Consistency and Quality: Every joist is perfectly straight, so there's no time wasted sorting through warped lumber.

Bay Area Labor Rate Considerations

Labor costs in the Bay Area are some of the highest in the country. A skilled framing contractor might charge anywhere from $75 to over $125 per hour. This depends on their experience and the job's complexity.

Proper installation is non-negotiable. TJI joists must be installed according to the manufacturer's specs to guarantee structural integrity. Cutting corners leads to expensive callbacks and repairs.

When you're pulling together project expenses, using good home construction budget templates can be a lifesaver. For a deeper dive into local cost planning, check out our guide on effective construction budget management.

How Bay Area Conditions Affect Project Costs

Building in the San Francisco Bay Area is unique, and that affects the total cost of TJI joists. From Berkeley's green building codes to the challenges of a tight San Francisco lot, regional factors will shape your budget. Understanding these local details is key to creating an accurate cost estimate.

The Bay Area's unique landscape demands a smart approach to materials and logistics. What works in Contra Costa County won’t work for a dense, urban project. These pressures are part of your final project expenses.

Navigating Strict Building Codes

California has some of the toughest building codes in the nation, especially for seismic and fire safety. These regulations dictate your floor system design and material choices. A job in a high-risk seismic zone might require a more robust series of TJI joists.

This can lead to higher material costs if stronger joists are needed. Fire safety standards, especially in Wildland-Urban Interface (WUI) zones in the East Bay hills, might require fire-retardant materials. You can discover more about safeguarding your home in our guide on weatherproofing windows and doors.

Sustainability and Green Building

Communities like Berkeley and Oakland lead the green building movement. Engineered wood products like TJI joists fit right in. They are made from fast-growing, sustainably harvested trees and optimize the use of wood fiber.

Engineered wood's efficiency has made it a market leader. According to industry data, solid flange I-joists typically cost around 20% less than comparable LVL options. This gives builders a cost-effective way to create strong, stable floor systems.

Logistical and Site-Specific Challenges

Building in the Bay Area brings its own cost factors. Delivering long TJI joists to a tight job site in San Francisco can increase delivery fees.

These logistical hurdles are common and include:

- Access Restrictions: Narrow streets or steep hillside locations can complicate material delivery.

- Storage Limitations: On-site storage space is often a luxury, requiring just-in-time deliveries.

- Labor Mobility: Moving materials around a constrained site can be more labor-intensive, adding to costs.

Frequently Asked Questions About TJI Joists

Choosing the right floor system is a big decision. Here are some of the most common questions we hear from builders and homeowners in Berkeley, Oakland, and the wider Bay Area. We'll tackle the details so you can plan with clarity.

Can I drill through TJI joists for pipes and wiring?

Yes, this is one of their biggest advantages. However, you must follow the manufacturer's guidelines precisely. Weyerhaeuser provides diagrams showing where and how large holes can be drilled in the OSB web without compromising strength. Never cut or notch the top or bottom flanges, as they provide the joist's strength.

How do TJI joists affect floor noise?

TJI joists create a very stiff and solid floor, which helps eliminate the squeaks common in older construction. To reduce impact noise like footsteps, consider adding sound-dampening materials like insulation in the joist cavities or an acoustic underlayment beneath your finished flooring. These strategies create a much quieter living space.

What is the lifespan of a TJI joist?

When installed correctly and protected from moisture, TJI joists are designed to last the life of the building. Because they are an engineered product, they resist warping, twisting, and shrinking over time. Proper weatherproofing during construction is essential to ensure their longevity, as they are still a wood-based product.

Are TJI joists a sustainable building material?

Yes, they are a great example of resource-efficient manufacturing. TJI joists are made from wood fiber sourced from smaller, fast-growing trees, often from sustainably managed forests. This process creates a high-performance product with far less waste than milling large beams from old-growth timber, aligning well with Bay Area green building priorities.

Where can I buy TJI joists in the Berkeley area?

Your best source is a professional building material supplier like a dedicated lumberyard. At Truitt & White, we not only supply TJI joists but also provide expert advice to ensure you select the right series and depth for your project's engineering and local code requirements. We also have the logistical expertise to deliver materials to challenging Bay Area job sites. You can see answers to other common construction questions on our FAQ page.

Ready to start planning your next project? The experts at Truitt & White have the knowledge and inventory to help you select the right TJI joists and get your materials to the job site on time. Visit our Berkeley location or connect with us today for a personalized quote.