What's the biggest mistake builders make when choosing lumber and windows? It's focusing on the upfront cost instead of the long-term value. This mindset can seriously compromise a home's future durability and efficiency, especially in the Bay Area.

Let's dig into the critical details builders sometimes miss, from understanding lumber grades to picking the right window glazing for our unique microclimates.

Building for Today Versus Building to Last

We get it. In the fast-paced Bay Area market, balancing budgets and hitting deadlines is crucial. But small decisions on materials today can have huge ripple effects tomorrow.

Grabbing lower-grade lumber or a generic window might trim the initial invoice. However, it often leads to premature rot, structural issues, or sky-high energy bills for your clients.

These aren't just minor details—they're the difference between a home that stands strong for decades and one that becomes a money pit. Sustainable design and smart material choices are what eco-conscious clients now expect.

The Real Cost of Common Oversights

Choosing the right materials is a direct investment in a building’s resilience. This is a must in a region that swings from San Francisco's coastal fog to Oakland's inland heat. A deep understanding of these factors is what separates a good build from a great one.

To help you avoid common pitfalls, we've put together this table contrasting common corner-cutting with a high-performance approach. It's a quick reference for making smarter choices.

| Common Oversight | Short-Term Benefit | Long-Term Consequence | High-Performance Solution |

|---|---|---|---|

| Ignoring Lumber Grade | Lower material cost. | Structural weakness, poor finish quality, potential for call-backs. | Selecting the appropriate grade for load-bearing and finish applications. |

| Overlooking Window Glazing | Cheaper window unit price. | High energy bills, discomfort, non-compliance with Title 24. | Matching U-factor & SHGC to specific climate zones (e.g., coastal vs. inland). |

| Neglecting Moisture Management | Faster installation, saves a few minutes. | Premature rot in door frames and siding where wood meets concrete. | Installing proper capillary breaks and flashing systems. |

| Choosing Generic Siding | Readily available and inexpensive. | Fading, warping, and frequent maintenance or replacement. | Using materials like engineered wood or fiber cement rated for the local climate. |

These small shifts in focus—from price tag to performance—are what truly define a quality, lasting build.

Here’s a quick rundown of the most frequent misses we see:

- Ignoring Lumber Grade: Many builders only look at dimensions (2×4, 2×6) without considering the wood's structural integrity. This impacts everything from load-bearing capacity to how well finishes hold up.

- Overlooking Window Glazing: It's easy to pick windows based on style. But failing to match the U-factor and SHGC to a Berkeley hillside versus an East Bay valley home is a recipe for poor performance.

- Neglecting Moisture Management: Forgetting to create proper capillary breaks where wood meets concrete is a classic mistake. It’s a simple, low-cost step that prevents the inevitable rot that creeps into doors and frames.

Recent insights show that over 59% of architects and builders research materials online but struggle to find region-specific guidance. This gap highlights how critical local expertise is for picking products that perform in the Bay Area.

By getting a handle on what to look for, you can learn more about choosing the right eco-friendly construction materials that nail both performance and sustainability goals.

The Hidden Risks of Lower-Grade Lumber

Choosing lumber based only on price is a big mistake. You might save a few bucks upfront, but you’re creating a weak link that compromises the whole structure. Too many builders treat lumber like a simple commodity, but the grade is a direct measure of its strength, stability, and reliability.

Lower-grade lumber isn't just about looks; it introduces hidden risks that can haunt a project for years. These pieces often have knots, splits, and grain issues that act as weak points. This is a huge deal in the Bay Area, where seismic activity means every structural component must perform as engineered.

Understanding Lumber Grading for Stability

One of the most critical factors is bending strength, or the lumber's ability to resist a load without snapping. A floor joist or roof rafter is constantly under this pressure. Defects like large knots interrupt the wood's natural grain, creating stress points where failure is most likely to start.

Opting for lower-grade wood to save a few dollars can lead to sagging floors, cracked drywall, and costly repairs. It turns a one-time material choice into a long-term liability for both the builder and the homeowner.

This problem is even trickier with reclaimed wood. While popular for its character, its past life can hide serious weaknesses like old nail holes or hidden decay. For a deeper look at how grades are determined, check out our guide on understanding framing lumber grades.

The Real-World Impact of Poor Lumber Quality

This isn't just theory—it's backed by numbers. Research on reclaimed Douglas-fir shows its average bending strength can be around 25% lower than new, properly graded lumber. That’s a massive drop tied to the accumulation of defects over time.

For builders in Berkeley, Oakland, and across the Bay Area, the material's history and grade are everything. Investing in high-quality, graded lumber isn't an expense; it’s how you build a reputation for durability and excellence that lasts.

How Lumber Quality Defines Engineered Wood Performance

Engineered wood products like Cross-Laminated Timber (CLT) are popping up all over the Bay Area. They’re a fantastic sustainable building option. But their performance comes down to the quality of each individual piece of lumber inside them.

Using lower-grade lumber creates hidden weaknesses that can compromise the entire structure down the road. It’s a problem you can’t even see from the outside.

The Unseen Risks of Inferior Components

When lower-grade lumber is buried inside an engineered product, you’re inviting serious issues. These defects can silently undermine the building's long-term performance and safety.

Two of the biggest culprits are:

- Glue-Line Failures: If the lumber has knots or an inconsistent grain, the adhesive can't get a proper grip. This creates weak spots where layers can separate under stress.

- Rolling Shear Issues: This is a specific failure where wood fibers in one layer peel away from an adjacent layer. It's a problem far more common in lower-grade wood.

These aren't just minor blemishes; they are critical failures. They can impact a building's ability to handle everyday loads, let alone the seismic forces we plan for in California. For a deeper dive, check out our guide on what is engineered wood.

The Data Behind Durability

You don't have to take our word for it—the research backs this up. Controlled tests consistently show a direct link between lumber grade and the strength of engineered panels. One study showed CLT panels from higher-grade lumber had significantly better bending strength.

Even more telling was how they failed. The lower-grade panels were much more likely to give out due to poor adhesive bonds and inherent weaknesses in the wood itself.

To meet California's tough building codes and deliver a product that lasts, you must ensure every single layer meets high standards.

Getting a handle on understanding the differences between solid wood and engineered wood is the first step. This knowledge empowers you to select materials that are tough enough for tomorrow’s challenges.

How Moisture Silently Destroys Windows and Doors

Ever see a brand-new wood door rot from the inside out in just a few years? The problem often isn’t the door itself. It’s a tiny, overlooked detail during installation that lets moisture creep in.

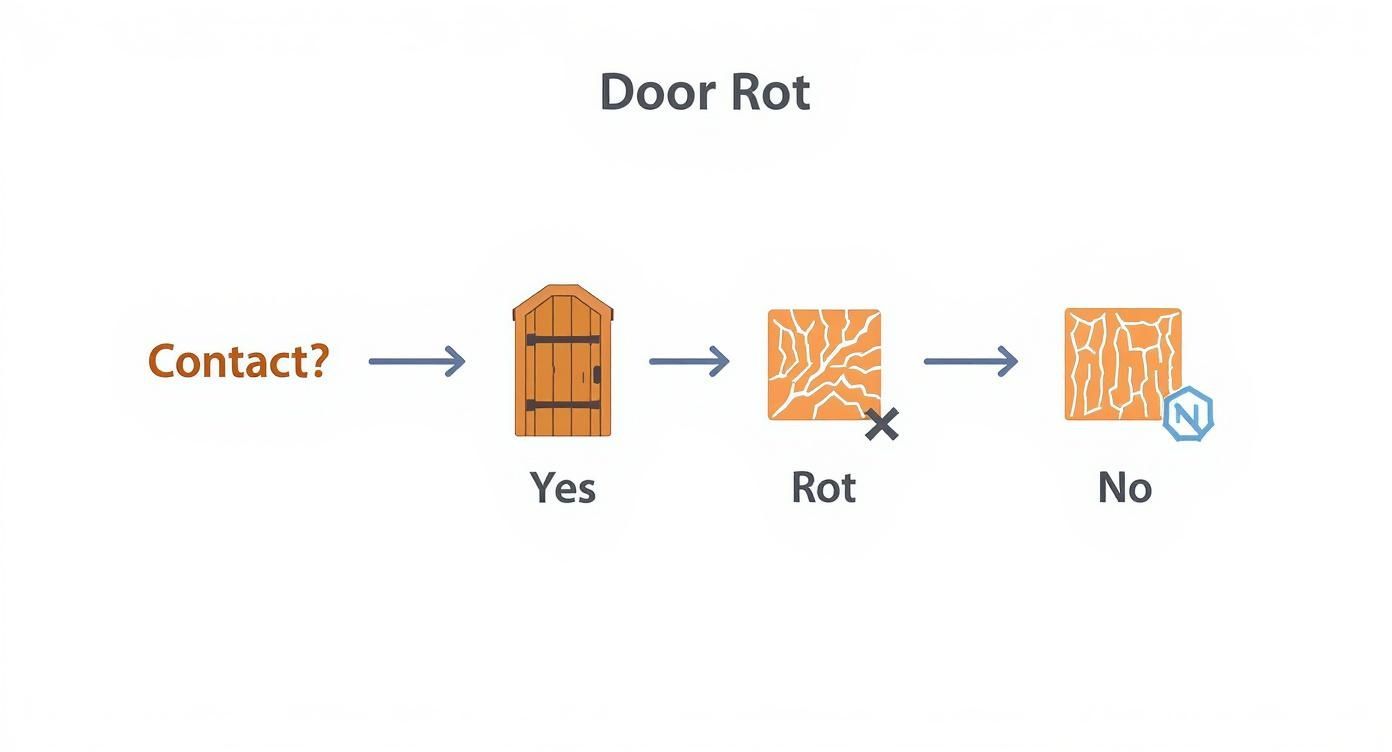

Too often, we miss the small but critical points where wood meets other materials. A classic example is a wooden door frame sitting directly on a concrete stoop. These contact points become superhighways for moisture.

Understanding Capillary Action: The Silent Culprit

This process is driven by capillary action. Think of how a paper towel wicks water up from a puddle. Wood acts the exact same way when it’s in direct contact with damp concrete.

This detail gets missed all the time, and the consequences are costly. Studies confirm rot can appear in wood doors in as little as three years, even when they’re properly painted. Sectional garage door panels are especially vulnerable.

The good news is that a simple, inexpensive fix can prevent thousands in damage. An air gap, a rubber gasket, or a metal sill pan creates a capillary break, stopping moisture transfer in its tracks. Check out our guide on weatherproofing windows and doors for more.

Protecting The Entire Building Envelope

Preventing direct moisture transfer is critical, but it’s not the whole story. The goal is to protect the entire building envelope so water never reaches these sensitive areas. This is a must in the damp, foggy climates of coastal San Francisco or parts of Berkeley.

Equally important is proper air and water barrier installation. A well-executed barrier system, combined with meticulous flashing and sealing around every window and door, creates a complete defense. This integrated approach is what many builders miss.

By focusing on these micro-details at installation, you shift from simply installing a product to engineering a lasting solution for the Bay Area's unique environmental pressures.

Selecting Windows for Bay Area Microclimates

Picking a generic "energy-efficient" window just doesn't work in the Bay Area. Our region is a patchwork of microclimates, which demands a smarter approach. A one-size-fits-all strategy leads to uncomfortable homes and high energy bills.

The secret is understanding two key numbers required by California’s Title 24 energy code. They tell you the real story of how a window will perform in a specific location.

Decoding Window Performance Metrics

The two most important ratings are the U-factor and the Solar Heat Gain Coefficient (SHGC). They are like a window's performance DNA.

- U-factor: This tells you how well a window stops heat from escaping. A lower U-factor is better, meaning it's a superior insulator. That’s what you want for a cool Berkeley morning.

- Solar Heat Gain Coefficient (SHGC): This measures how much of the sun's heat a window blocks. A lower SHGC is better for preventing a house from overheating, a must-have for hotter inland areas.

For instance, a coastal San Francisco home needs a low U-factor to hold onto heat. But an inland home needs a low SHGC to block intense sun and keep cooling costs down.

This graphic shows how a tiny oversight—like forgetting a capillary break—invites moisture and causes big problems. The small stuff makes all the difference.

Matching Glazing and Frames to the Climate

The physical makeup of the window also plays a massive part. Double- or triple-pane glazing with argon gas and a Low-E coating is the standard for high performance. The type of Low-E coating should be matched to the home’s orientation to the sun.

The frame material is another crucial piece. Vinyl is a solid insulator, while fiberglass offers incredible strength and stability for our region’s temperature swings. Wood-clad frames give you a classic look with modern performance.

Making the right choice is about more than comfort; it’s about durability and compliance with California's Title 24. To see what top-tier manufacturers offer, explore the options for quality windows in the East Bay.

Your Partner in Building for the Long Haul

Building a home that stands the test of time in the Bay Area means looking past the initial price tag. It's about getting the details right—like correct material grading and picking windows suited for our climate. This is where decades of local, hands-on experience really count.

Truitt & White isn't just another lumberyard near Oakland. We are your dedicated partner, here to help you navigate the tricky decisions that separate a good build from a great one. Our team knows what builders often miss.

Local Experts Who Know High-Performance Materials

We’ve spent years building relationships with premier brands like Marvin and Andersen. This lets us offer windows and doors that exceed California's tough Title 24 codes. From FSC-certified lumber to fire-rated materials for a hillside project, our inventory is curated for Bay Area challenges.

We help turn material selection into a long-term investment in durability, efficiency, and your client's peace of mind. Our goal is to help you build homes that meet today's standards and are ready for tomorrow's expectations.

Contractors, designers, and homeowners in the Bay Area can consult our local specialists. Stop by our Berkeley showroom to explore performance-tested materials tailored to the region.

For a one-on-one consultation, connect with our team of specialists.

Frequently Asked Questions About Lumber and Windows

Our team has heard it all from builders, architects, and homeowners across the Bay Area. Here are answers to some of the most common questions we get.

How do I know I'm getting the right grade of lumber?

Look for the grade stamp directly on the piece of lumber. This is a guarantee from a certified grading agency that the wood meets specific structural standards. If you’re unsure what a stamp means, our team can confirm you have what your project's engineering requires.

Are high-performance windows really worth the cost in the Bay Area?

Absolutely. High-performance windows are your first line of defense against energy loss, keeping your home cooler in summer and warmer in winter. They also improve comfort, reduce condensation, and are often required to meet California’s strict Title 24 energy codes.

What's the biggest mistake in wood door installations?

Failing to isolate the bottom of the door from direct contact with concrete. Wood wicks up moisture like a sponge, causing rot from the inside out. A quality gasket or a proper sill pan creates the capillary break needed to prevent this common and expensive issue.

Should I use different types of windows on different sides of a house?

Yes, this strategy is known as "solar tuning." For south- and west-facing walls that get intense sun, you’ll want windows with a lower Solar Heat Gain Coefficient (SHGC) to block heat. On the north side, you can use windows with a higher SHGC to pull in natural light.

What lumber should I use for building in fire-prone zones like the Oakland Hills?

In high-risk fire zones, using fire-rated materials is often the law. Your best options are typically pressure-treated fire-retardant lumber or certain dense hardwoods that have a natural resistance to burning. We can walk you through the exact materials you'll need to make your project compliant and safe.

Ready to select materials that guarantee long-term performance? The experts at Truitt & White are here to help. Visit our Berkeley showroom for personalized advice.