More than just a line item in your project plan, construction materials delivery is the lifeblood of a successful build. For builders, contractors, and remodelers in the fast-paced Bay Area, getting the right materials to the right place at the right time isn't just a nicety—it's what keeps your project moving, protects your profits, and solidifies your reputation.

Why On-Time Material Delivery is Your Project’s Lifeline

Picture your project schedule as a line of dominoes. One late delivery, whether it's framing lumber for a new build in Oakland or custom windows for a remodel in Berkeley, can set off a chain reaction of costly delays. When materials don't show up, work grinds to a halt, but the meter on your expenses keeps running.

This is where the financial pressure really mounts. A skilled crew standing around for even half a day can cost you thousands in wages, eating directly into your bottom line. Worse, these hiccups throw your subcontractor schedules into chaos, pushing back electricians, plumbers, and finishers.

The True Impact of Bay Area Project Delays

The fallout goes beyond the immediate financial hit. The construction world is still grappling with major hurdles like supply chain snags, unpredictable prices, and labor shortages. These challenges, which have lingered for years, routinely delay projects and inflate costs, putting the squeeze on everyone from architects to homeowners. This environment makes early procurement and precise planning more critical than ever.

A smart delivery strategy isn't just about damage control; it's a genuine competitive advantage. It means your resources are used efficiently, your crews stay productive, and your project stays on schedule and on budget.

From Logistics to a Proactive Delivery Strategy

The key is to shift your thinking from reactive to proactive. Don't just order materials; build a delivery strategy from the very beginning of the project.

What does that look like in practice for a Bay Area build?

- Early Collaboration: Talk to your supplier from day one. Get a real understanding of lead times, especially for specialty or custom-ordered items like Marvin windows or specific siding.

- Phased Deliveries: Schedule materials to arrive just as they’re needed. This avoids cluttering a tight Berkeley job site and keeps things organized.

- Clear Communication: Ensure your supplier knows every detail about the job site—access points, drop-off locations, and any potential obstacles like narrow Oakland hills roads.

This guide will walk you through how to turn your construction materials delivery process from a potential headache into one of your project’s greatest strengths.

Creating Your Delivery Blueprint Before You Build

A great construction project doesn't start when the first truck pulls up; it starts with a detailed delivery blueprint. This isn't just a list of materials; it's a strategic plan to get every piece of lumber, every box of nails, and every custom window to the site right when your crew is ready for it. No more costly downtime.

Your project blueprints are more than just a guide for the build itself; they're your starting point for a construction materials delivery schedule. You begin with a thorough material takeoff, translating the architect's vision into a real-world shopping list. But it's not just about what you need; it's about when you need it.

From Blueprint to Phased Ordering for Bay Area Projects

Smart delivery planning means breaking the entire project into logical phases. You wouldn't order drywall before the framing is even up, and this logic applies to everything. A phased approach keeps your job site from turning into a chaotic storage yard, protecting valuable materials from damage, theft, or the unpredictable Bay Area weather.

Your delivery schedule should be a direct reflection of your building timeline:

- Phase 1: Foundation and Subfloor: This is all about concrete, rebar, anchor bolts, subfloor adhesives, and sheathing.

- Phase 2: Framing and Roofing: Time for framing lumber, engineered wood products from a "lumberyard near Oakland," house wrap, and all your roofing materials.

- Phase 3: MEP and Insulation: Next up are the rough-in materials for mechanical, electrical, and plumbing, followed immediately by insulation that meets California's Title 24 energy standards.

- Phase 4: Finishes: The final stretch includes drywall, doors, windows, trim, and flooring.

Organizing your deliveries this way keeps your job site in Oakland or Berkeley clean and, more importantly, efficient. It gives your trades the space they need to work without tripping over materials that shouldn't be there yet.

The Power of Early Supplier Collaboration

Bringing your materials supplier into the loop early on is one of the smartest moves you can make. When you start talking with a trusted partner like Truitt & White from the beginning, they become a core part of your logistics team. This is especially true for any Bay Area project with custom or long-lead-time items.

By partnering with your supplier at the planning stage, you can reserve critical inventory, get accurate lead times for products like custom Marvin windows, and lock in pricing before market volatility impacts your budget. It’s the single best way to de-risk your project schedule.

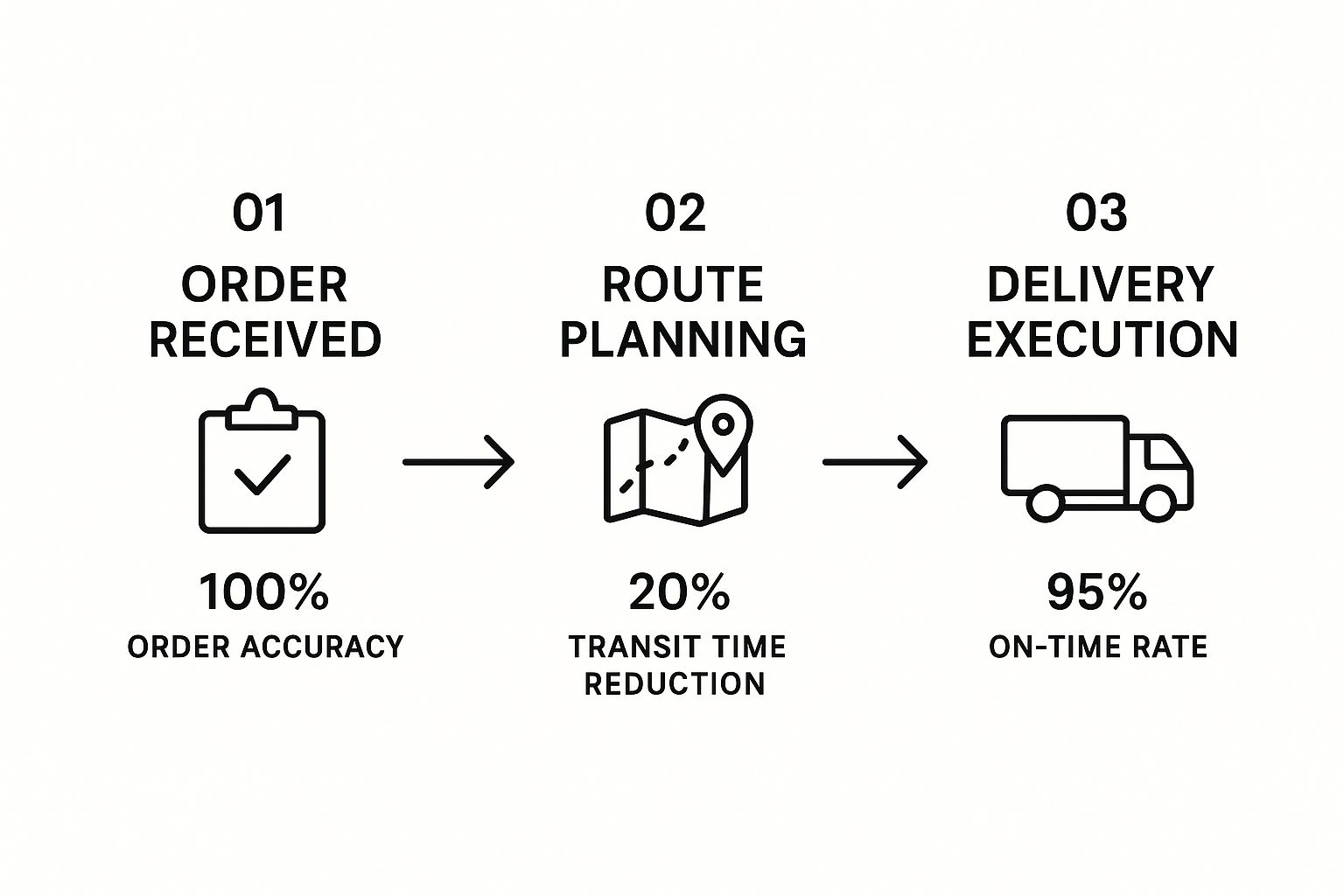

This infographic breaks down our process, built around getting things right from the moment you place an order.

When you walk us through your project timeline, we can help map out a delivery schedule that clicks perfectly with your crew's workflow. We’ve been sourcing building material supplies for the San Francisco Bay Area for over 75 years, so we know how to anticipate potential supply chain hiccups. That kind of foresight is what prevents that nightmare scenario: a whole crew standing around because a critical delivery is late.

A well-thought-out delivery plan also makes site management a breeze. You can tell us exactly where to drop specific materials, which cuts down on your team’s time and effort. The goal is to have the framing package staged and ready when the framers arrive, not buried under a pile of roofing supplies that showed up weeks too early.

Navigating Complex Bay Area Job Site Logistics

A successful construction materials delivery in the Bay Area is about more than just getting from point A to point B. It's a masterclass in precision planning and deep local knowledge.

From the notoriously tight streets of San Francisco to the steep, winding roads in the Berkeley and Oakland hills, every job site presents its own logistical puzzle. Overlooking these challenges can lead to delays, damaged materials, and a frustrated crew.

The Art of Staggered Drop-Offs on Tight Sites

The single best strategy for managing a tight job site is scheduling staggered deliveries. This "just-in-time" approach prevents your site from turning into an impassable storage yard. By working closely with your supplier, you can get materials to arrive exactly when your crews are ready for them.

It’s a simple, logical flow:

- Week 1: The framing package lands. Your crew can get right to work without tripping over pallets of siding or roofing.

- Week 3: Just as the framing is wrapping up, the windows and exterior doors are delivered.

- Week 5: Once the building is sealed up, the drywall and insulation can be dropped off and brought inside immediately, safe from the elements.

This rhythm not only keeps your site clean and organized but also dramatically cuts down on the risk of materials getting damaged. It all comes down to clear communication with your supplier, but the payoff in efficiency is massive.

A well-executed delivery schedule means your crews are always productive because the materials they need are exactly where they should be, exactly when they need them. This is where a local supplier’s expertise becomes a true asset.

Specify Your Drop Location with Precision

Just telling your supplier to “drop it at the job site” is a recipe for wasted time and labor. Your crew’s expensive time shouldn't be spent hauling materials from the curb to the far side of the property. When you place your order, you need to be obsessively specific about the drop location.

Give clear, simple instructions:

- “Place the lumber package on the north side of the driveway, near the garage foundation.”

- “Stack the drywall sheets just inside the garage door, out of the rain.”

- “Leave the windows on the back patio, under the temporary cover.”

Taking 30 seconds to do this can save your team hours of manual labor. Sending a quick photo or a simple site map to your supplier can eliminate all guesswork.

Why Confirming Truck Size is Non-Negotiable

The Bay Area is loaded with logistical traps for large delivery trucks. A standard flatbed that works perfectly for a wide-open suburban home might not even make the turn onto a narrow street in the Oakland hills or navigate a tight alley in San Francisco. This isn't a minor detail—it's a critical one that you must confirm with your supplier.

A good supplier with local experience will have a diverse fleet ready for these situations. Talking through the site access ahead of time turns a potential logistical nightmare into just another smooth, professional delivery.

Bay Area Delivery Challenge and Solution Checklist

| Challenge | Planning Question | Solution / Best practice |

|---|---|---|

| Street Access | Are there tight corners, one-way streets, or weight-restricted roads on the delivery route? | Review the route on a map and communicate any potential issues to your supplier. Ask them to confirm the planned route. |

| Overhead Obstructions | Are there low-hanging power lines, phone lines, or large tree branches over the site or street? | Walk the site and the street in front. Note any overhead hazards that could limit a boom truck's operation. |

| Site Grade & Surface | Is the job site on a steep hill? Is the driveway paved, or is it mud, gravel, or dirt? | Inform your supplier about the grade. A 4×4-capable truck or a smaller vehicle might be necessary for steep or unpaved sites. |

| Neighborhood Rules | Are there specific HOA rules or city ordinances about delivery times or parking? | Check with the homeowner or local jurisdiction. Some areas restrict commercial vehicle access during certain hours. |

| Staging Area | Is the designated drop spot clear and accessible, or is it blocked by other trades, vehicles, or debris? | Coordinate with other subcontractors. Ensure the drop zone is clear before the truck is scheduled to arrive. |

Using a checklist like this is a simple but powerful way to get ahead of problems. A few minutes of planning can prevent hours of costly delays on delivery day.

The True Cost of Inefficient Material Deliveries

Poorly managed construction materials delivery is a silent profit killer. The invoice for your lumber or windows shows what you paid for the product, but it never itemizes the real-world expenses when logistics go sideways.

These hidden costs show up in painful ways right on your job site. Picture it: an entire framing crew waiting for a lumber drop-off, or a project timeline that slips by a week, then two. Every delay creates a ripple effect, disrupting the next trade in line and throwing your whole schedule into chaos.

The Financial Drain of Idle Crews and Project Delays

The most immediate cost of a late delivery is idle labor. Your crew is on the clock whether they're swinging hammers or just waiting. A single day of delay for a five-person framing crew in the Bay Area can easily cost over $2,000 in wages alone—enough to wipe out the profit on that phase of the job.

It's a domino effect from there. Pushing your schedule back can trigger penalty clauses in your contract or strain your relationships with subcontractors. When you have to tell them to push back, they have to reshuffle their own teams, and your project might get moved to the back of their line.

According to the National Association of Home Builders (NAHB), construction delays are a primary concern for builders, with "Building Material Prices/Availability" being a top challenge. A reliable delivery partner directly helps you mitigate this massive, systemic drain on profitability.

Material Damage and Loss on a Crowded Job Site

Shaky delivery logistics create another huge expense: material damage, theft, and waste. When deliveries aren't phased properly, your job site turns into a disorganized storage yard.

- Damage: Materials like drywall or windows left exposed to the Bay Area’s damp climate can be ruined before they're ever installed. Items also get damaged simply from being moved around multiple times.

- Theft and Vandalism: The more valuable materials you have sitting on an unsecured site, the bigger the target you become for theft.

- Waste: When a site is a mess, it’s almost impossible to track what you have. This leads to costly and unnecessary reorders. For tips on picking products that can handle the job site environment, check out our guide on choosing durable contractor materials.

The Powerful Upside of a Fine-Tuned System

Now, flip the coin. The upside of an optimized delivery system is immense. When you work with a supplier who has their logistics dialed in, you unlock powerful advantages that go straight to your bottom line. A smooth construction materials delivery process improves your cash flow, since you're paying for materials closer to when they're actually installed and billed.

Ultimately, a dependable delivery partner is one of your best tools for minimizing waste and boosting your capacity to take on more projects each year. By turning deliveries from a constant source of stress into a strategic advantage, you build your reputation, improve your profitability, and get to focus on what you do best: building.

Choosing a Supplier is Choosing a Strategic Partner

In the Bay Area's competitive construction scene, it's easy to treat your materials supplier like a vending machine. But simply chasing the lowest price on a sheet of plywood misses the bigger picture. Your relationship with your supplier is one of your most important strategic partnerships.

When you choose a supplier, you're choosing a key member of your project team. Their performance has a direct line to your efficiency, your reputation, and your bottom line. A purely transactional vendor sells you what's on the list; a true partner acts like an extension of your own crew, anticipating what you'll need on a hectic job site in Berkeley or Oakland.

Beyond the Price Tag: What Defines a True Partner

Of course, cost matters. But a supplier's real worth is measured in their reliability and the depth of their expertise. Having a partner you can count on gives you a competitive edge that small savings on an invoice could never match.

So, what does a real partner look like?

- Unwavering Reliability: You can set your watch by their delivery schedule. They understand a single delayed construction materials delivery can bring your entire operation to a standstill.

- Proactive Communication: They give you a heads-up about potential supply chain snags, they confirm delivery windows, and they're actually reachable when plans change.

- Deep Product Knowledge: Their team knows "Berkeley building materials." They can recommend smart alternatives or suggest a better, more cost-effective material for the job.

This is the kind of service that turns a supplier from a line item on your budget into a powerful asset. Sourcing high-quality lumber in the East Bay from a team that knows the material inside and out can completely change your project outcomes.

Your Supplier as a Competitive Advantage

Picture this: you have a dedicated account manager who knows the DNA of your projects. They understand the specific windows you favor for historic remodels in San Francisco and the exact engineered wood products you count on for new builds. That kind of relationship is built on trust and the shared goal of getting the job done right.

A supplier who acts as a strategic partner doesn't just fulfill orders; they actively contribute to your project's success. Their expertise in materials and logistics becomes your expertise, freeing you to focus on managing your crew and building to the highest standard.

This partnership is only becoming more critical. As demand for specialized materials climbs, having a supplier who can navigate this tricky landscape and secure what you need is priceless. The global construction materials market is projected to grow to USD 2.47 trillion by 2032, according to a report from Precedence Research.

At the end of the day, a great supplier delivers more than just materials—they deliver peace of mind. They’re the ones who will hustle to get a forgotten item to your site and provide the kind of dependable service that makes your job easier. That’s not a vendor; that’s a partner.

Your Partner for Bay Area Construction Success

Let's be honest: getting construction materials delivery right is a skill that directly pads your bottom line and cements your reputation in the Bay Area's tough market. It’s about proactive planning, navigating our unique local hurdles, and building a rock-solid relationship with your supplier. These are the pillars that turn delivery from a daily headache into a real strategic advantage.

Ultimately, a successful project isn't just about what you build, but how you build it. Smooth logistics are the unsung hero of a profitable, well-managed job, giving you the freedom to focus on the craftsmanship your clients expect.

Make Truitt & White Your Go-To Resource

For decades, we haven't just been selling lumber and windows; we've been an integral part of the Bay Area's building fabric. Our team is ready to help you map out a delivery strategy that fits your project perfectly, whether you're tackling a tricky historic remodel in San Francisco or a brand-new build in the Oakland hills. We get the challenges because we’re out there solving them with contractors like you every single day.

When you choose a partner with deep local roots, you're choosing someone you can count on. Our legacy goes back to 1946, and our promise has always been the same: provide the kind of dependable service that keeps your projects moving forward.

This isn't just business for us; it's about relationships. We've been a cornerstone of this community for a long time, and you can learn a bit more about that by reading about Truitt & White's 75-year history in Berkeley.

We want to be your go-to resource. Our team is here and ready to help you build smarter, faster, and more profitably. Swing by our Berkeley showroom or contact us today and let's get started.

Frequently Asked Questions About Construction Materials Delivery

1. How far in advance should I order my building materials?

For in-stock items like framing lumber or drywall, planning 3-5 business days ahead is a good rule of thumb for projects in the Bay Area. For special order products like custom windows and doors, you should place your order as soon as they are specified, as lead times can be 6-12 weeks or longer.

2. What information do you need for a smooth delivery to a Bay Area job site?

To ensure a smooth delivery, please provide the full job site address, a primary on-site contact name and phone number, and any special instructions. Details like gate codes, narrow streets in San Francisco, or steep Oakland hills driveways help our dispatchers send the right vehicle and prepare our drivers.

3. Can I request a specific delivery time?

Yes, you can request a specific delivery window, like "morning" or "afternoon." While Bay Area traffic makes it hard to guarantee an exact minute, giving us advance notice helps us schedule our routes to accommodate your needs as closely as possible.

4. What should I do if my material order arrives damaged?

Inspect your order as soon as it arrives, preferably while the driver is still on site. If you find any damage, take photos, note the issue on the delivery receipt before signing, and call your Truitt & White sales representative immediately so we can resolve it quickly.

5. How can I avoid clutter on my job site?

The best way to prevent clutter is to schedule phased or "just-in-time" deliveries with us. Instead of receiving everything at once, we can deliver your framing package, windows, and finishing materials separately, right as your crew is ready for each stage.

At Truitt & White, we're more than just a supplier; we're your partner in building success. Visit our Berkeley showroom or contact our experts today to plan the logistics for your next project.