When you hire a contractor for a project in the Bay Area, the quote you get for materials is more than just the sticker price of lumber and paint. It includes something called a contractor markup on materials—a percentage added to the wholesale cost of the supplies.

This markup is a standard industry practice. It’s similar to how a restaurant bill covers more than just the food; it covers the chef's expertise, kitchen operations, and service. A contractor's markup functions the same way for your construction project.

What Is a Contractor's Material Markup?

A contractor's material markup is a fee that covers the contractor’s business overhead and the professional service of managing the entire material purchasing process. It's the engine that allows a professional to run a sustainable business and deliver a high-quality, fully managed project.

This fee isn't just extra profit. It's a calculated charge that bundles several critical services and risks. For builders working in high-cost areas like Berkeley and Oakland, this markup is essential for running a healthy business.

Beyond the Price Tag: What the Markup Covers

It’s easy to see the markup as an unnecessary charge, but it pays for crucial logistics and expertise. It ensures the right materials get to your job site on time and in perfect condition.

Here's a look at what the markup accounts for:

- Logistics and Coordination: This covers the hours spent sourcing materials from trusted suppliers, like our contractor supply store in Berkeley, placing orders, and scheduling deliveries.

- Risk and Responsibility: The contractor assumes the financial risk if materials arrive damaged, the wrong items are sent, or a shipment is lost.

- Overhead Costs: This helps cover the daily expenses of running a business, like liability insurance, work trucks, office space, and employee wages.

- Professional Service: You're paying for the contractor’s experience in selecting materials that meet strict Bay Area building codes and climate demands.

Understanding the fundamentals of starting a contracting business is key for new contractors. This includes learning how to structure costs and pricing fairly.

Anatomy of a Contractor's Material Markup

The table below breaks down the components of a material markup. This gives you a clearer picture of what your investment covers.

| Markup Component | What It Covers | Example |

|---|---|---|

| Procurement & Sourcing | Time spent researching, vetting, and ordering materials from multiple vendors. | A contractor spends hours finding the exact reclaimed wood a San Francisco client wants. |

| Logistics & Delivery | Coordinating shipping schedules, receiving shipments, and transporting materials to the job site. | Arranging a crane to deliver roof trusses to a site in the Oakland Hills. |

| Risk & Insurance | Covering the cost of damaged, lost, or incorrect materials; liability for storage. | A pallet of expensive tile is damaged in transit; the contractor replaces it at their cost. |

| Business Overhead | A portion of general business expenses like insurance, vehicle maintenance, and office rent. | The fuel and wear-and-tear on the company truck used to pick up supplies. |

| Profit Margin | The amount earned by the business after all costs are covered. | The funds needed to invest in better tools, training, and company growth. |

This breakdown shows that the markup is a multi-faceted charge. It ensures the project runs smoothly and the contractor's business remains healthy.

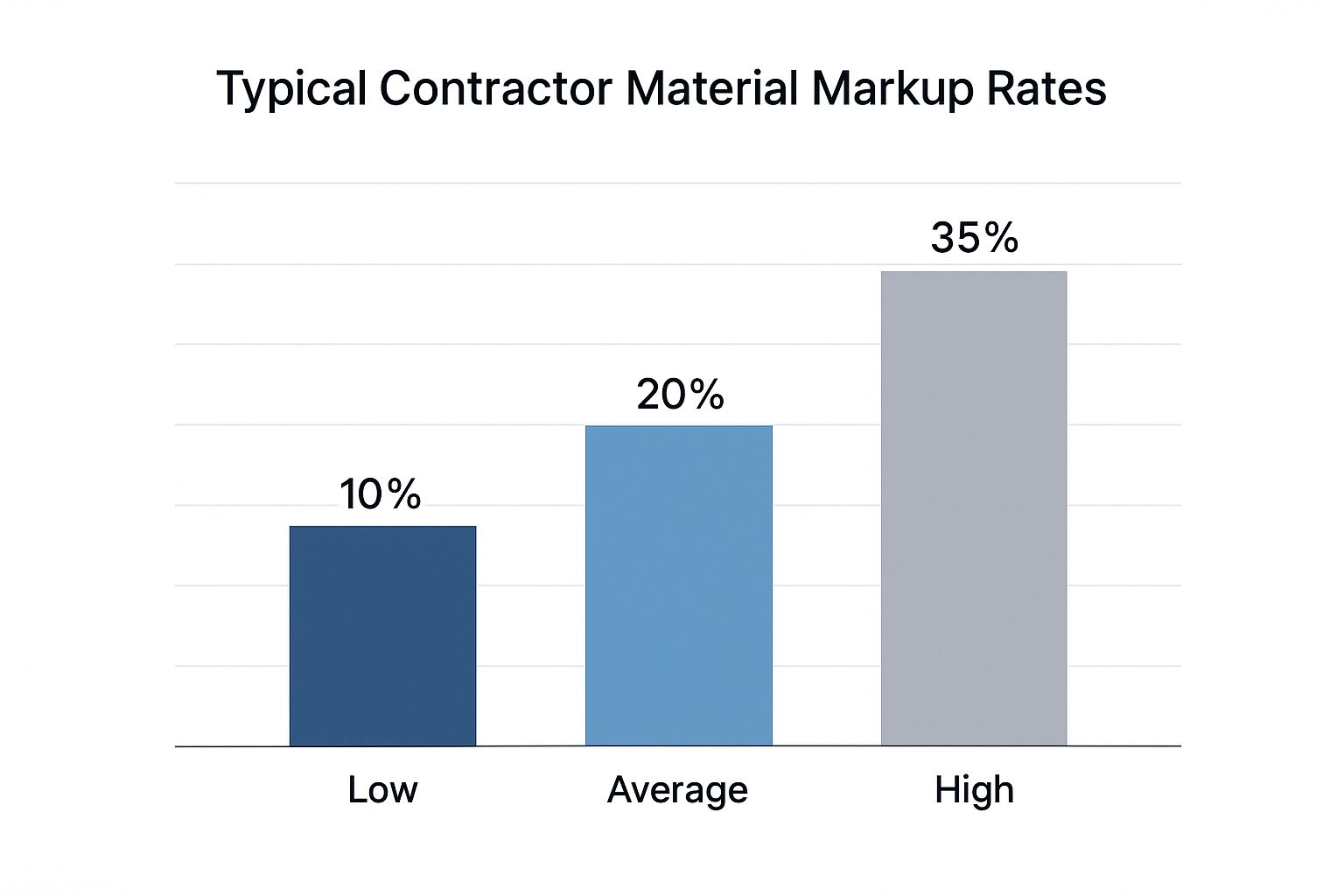

As you can see, the percentages can vary. They always reflect the significant overhead and risk that contractors manage to keep your project on track.

How Contractors Calculate Material Markups

Let's look at how a contractor markup on materials is calculated. The most common method is straightforward: applying a percentage to the direct cost of the materials.

This approach is a fair and consistent way for a contractor to cover their overhead, service, and risk. Let’s dig into the go-to calculation method in the construction world.

The Cost-Plus Model Explained

The most common method for calculating markups is the Cost-Plus model. The contractor takes the actual cost of materials and adds a pre-agreed-upon percentage.

This model is popular because it's transparent and easy for everyone to follow. The "cost" is the wholesale price of the materials. The "plus" is the markup percentage that covers the contractor’s services and business expenses.

Key Takeaway: With a Cost-Plus model, the math is direct: (Wholesale Material Cost) + (Wholesale Material Cost x Markup Percentage) = Your Final Price. This simple formula is the foundation of most material pricing in construction bids.

This clarity helps both the contractor and the client. It makes it easy to trace how the final numbers on an invoice came to be. Solid construction budget management is built on this kind of clear calculation.

A Real-World Bay Area Example

Imagine a contractor building a new redwood deck for a home in Oakland. They are sourcing all the lumber and hardware from a local supplier like Truitt & White.

Here’s how the numbers would work:

- Wholesale Material Cost: The contractor's total bill for all redwood lumber and hardware is $10,000.

- Applying the Markup: The contractor has a standard 30% markup on materials to cover overhead, logistics, and profit.

- Calculating the Markup Amount: They multiply the material cost by their markup percentage: $10,000 x 0.30 = $3,000.

- Determining the Final Price: They add the markup to the original material cost: $10,000 (Cost) + $3,000 (Markup) = $13,000.

The client’s invoice would show a line item for materials totaling $13,000. This covers the wood and screws, plus the contractor's service of sourcing, guaranteeing, and managing delivery.

Using Blended and Tiered Markups

Not all materials are the same. Some are harder to source or riskier to order. That’s why some contractors use a blended or tiered markup strategy.

This approach applies different percentages to different types of items. It allows contractors to price their services more accurately based on the complexity and risk involved.

A tiered markup strategy often looks like this:

- Standard Materials (20% Markup): For common items like framing lumber or drywall, the risk is low. A smaller markup makes sense.

- Specialty Materials (35% Markup): Think custom-milled trim or special-order fixtures. The contractor spends more time sourcing these and takes on more financial risk.

- Custom-Ordered Items (40%+ Markup): For high-end, custom products like architectural windows from Marvin, the stakes are much higher. These items often have long lead times and can't be returned, so the higher markup covers the significant risk.

This tiered system provides a more precise and fair picture of a project's costs. It ensures the markup aligns with the service provided for each part of the job.

Key Factors That Influence Markup Rates

A contractor markup on materials is not a one-size-fits-all number. It’s a dynamic figure that shifts based on the specific demands and risks of each job.

Understanding these variables is key for contractors setting fair prices and for clients who want to know what they're paying for. The final price should be a true reflection of the service provided.

Project Complexity and Scope

The biggest driver behind markup rates is the project's complexity. A straightforward bathroom remodel using standard materials requires less management than a custom home with unique architectural features.

Complicated jobs demand more of a contractor's time, expertise, and oversight. As a project gets more complex, the markup naturally increases.

- Low Complexity Example: A small deck repair using standard lumber might carry a lower markup, around 20-25%.

- High Complexity Example: A multi-story addition in the Berkeley Hills with custom siding and specialized windows will demand a higher markup, potentially 35-45%.

Type and Scarcity of Materials

The materials themselves also impact the final markup. Sourcing and handling different materials involves different levels of risk and effort.

Commodity materials like standard lumber or drywall are readily available and carry little risk, justifying a lower markup. Specialty or custom-ordered items require more logistical work and expose the contractor to more financial risk.

For instance, ordering custom Marvin windows for a historic restoration in San Francisco involves long lead times and non-refundable deposits. If those windows are measured incorrectly or damaged, the contractor is responsible. This risk warrants a higher markup than standard, in-stock products.

Many builders in the Bay Area focus on sustainable construction. Exploring options for https://truittandwhite.com/green-building can sometimes mean sourcing less common products, which can also influence the markup.

How Project Variables Affect Markup Percentages

The table below shows how different project variables can affect markup percentages. This gives a clearer sense of the pricing landscape.

| Factor | Impact on Markup | Bay Area Example |

|---|---|---|

| Project Size | Decreases with scale | A large commercial build may have a lower markup % than a small residential remodel. |

| Material Type | Increases for specialty items | Custom-fabricated steel beams will carry a higher markup than standard 2×4 lumber. |

| Project Duration | Increases with length | A year-long project requires more sustained management, increasing the markup. |

| Labor Skill | Increases for specialized trades | Projects requiring master artisans or certified installers command a higher markup. |

| Client Relationship | Can decrease for repeat clients | A contractor might offer a slightly lower markup to a trusted, long-term client. |

| Risk & Liability | Increases with higher risk | Working on a historic property in Pacific Heights increases liability and markup. |

Ultimately, a contractor's markup is a finely tuned calculation. It reflects the specific landscape of each job.

Local and Global Market Conditions

Construction projects are heavily influenced by local and global economies. In the Bay Area, high demand and steep operating costs create a different standard for markups than in other parts of the country.

Factors like local labor rates, fuel prices, and supply chain stability affect a contractor's overhead. Contractors must build a buffer into their pricing to shield projects from this volatility.

The Contractor’s Business Model and Overhead

Finally, the contractor's own business structure plays a major role. A larger company with an office, a fleet of trucks, and comprehensive insurance has higher overhead than a smaller operation.

These overhead costs allow a company to provide a high level of service and reliability. For contractors, managing business expenses is essential for setting prices that are both competitive and sustainable. Some look into proven ways to reduce fleet costs and boost profits.

A well-established contractor’s markup covers the fundamental costs of doing business right. This benefits the client through better project management and peace of mind.

Navigating Markups in a Volatile Economy

Contractors and clients in the Bay Area know that economic shifts impact construction costs. When the market is shaky, understanding the contractor markup on materials is critical for keeping projects on budget.

In unpredictable times, a contractor's markup acts as a buffer against sudden price increases. This is a defensive measure to protect the project’s finances from factors outside anyone's control.

The Impact of Supply Chain Disruptions

Global supply chains have been under immense pressure, causing material shortages and long delivery timelines. A window shipment that once took six weeks might now take six months, with the price increasing during the wait.

This uncertainty forces contractors to adjust their markup strategies. A slightly higher percentage helps absorb surprise price hikes that occur between the quote and the actual purchase of materials.

Inflation and Material Cost Volatility

Inflation also plays a major role. When the cost of raw materials like lumber and steel skyrockets, suppliers pass those increases down the line.

A contractor might need to adjust their markup to cover this risk. It acts as a financial cushion, ensuring the project can move forward even if material costs suddenly jump. For specialized trades, many contractors lean on partners for precise cost data. You can learn more about mechanical estimation for contractors to see how detailed this process gets.

According to the U.S. Bureau of Labor Statistics, extreme price swings from 2018 to 2022 caused 22.5% of contractors to raise markup rates. This was a direct response to protect their projects and businesses from the impact of tariffs and supply chain issues. You can read the full analysis from the U.S. Bureau of Labor Statistics.

Why Communication Is Key in Uncertain Times

When the economy is turbulent, explaining the "why" behind a markup is more important than ever. The foundation of a strong partnership between a contractor and client is clear, honest communication.

Contractors build trust by explaining how market conditions shape their pricing. This transparency helps everyone see that adjustments are a response to real-world economic pressures.

Here are a few ways to keep everyone on the same page:

- Explain Market Realities: Talk openly about current supply chain issues or price trends for your project's specific materials.

- Use Escalation Clauses: For longer projects, an escalation clause in the contract pre-establishes how unexpected material price increases will be handled.

- Provide Regular Updates: Keep the client informed about material orders and flag potential delays or cost changes as they arise.

By tackling economic hurdles with transparency, contractors and clients can manage expectations and build a resilient partnership.

How Transparent Pricing Builds Stronger Partnerships

Great construction projects are built on trust. In the Bay Area, where projects are complex and budgets are significant, that trust begins with an open conversation about the contractor markup on materials.

When pricing is transparent, a markup is understood as a fair price for a professional service. This shift is the bedrock of a healthy contractor-client relationship.

For Contractors: Explaining Your Value

The best way to build trust is to explain the value your markup delivers. You are providing a comprehensive service package that ensures the project runs smoothly.

When a client asks about your markup, be ready to break down what it covers. It’s about the essential, behind-the-scenes work that brings a project to life.

Be prepared to walk them through key services like:

- Expert Sourcing: Your experience selecting high-quality materials from trusted suppliers like Truitt & White, suited for the Bay Area's climate and building codes.

- Logistical Management: The complex coordination of orders, deliveries, and timing to keep the project moving forward.

- Quality Control: Your process for inspecting materials upon arrival, checking for damage, and handling any returns or replacements.

- Warranty and Guarantees: The peace of mind that comes from knowing you stand behind the materials and will handle any issues.

Framing it this way shows your markup is a tangible benefit that reinforces your role as a professional partner.

For Clients: Asking the Right Questions

As a client, your goal is to understand the value you're paying for. Asking smart questions fosters transparency and helps you compare bids meaningfully.

Instead of just trying to lower the markup, ask more productive questions:

- Could you walk me through what your material markup covers?

- What's your process for sourcing materials and ensuring their quality?

- How do you handle damaged or incorrect material deliveries?

- Does your warranty cover both labor and the materials you provide?

These questions open the door to a real conversation about service. Our guide on how to choose a contractor has more tips for vetting professionals in the Bay Area.

How Your Contract Type Affects Markup Transparency

The structure of your construction contract also affects how markups are handled. Different agreements offer different levels of visibility into material costs.

Key Insight: Understanding your contract type is crucial. It sets the rules for how transparent material costs will be and how pricing is shared and approved.

Let's look at the two most common contract types:

- Cost-Plus Contract: The client pays the actual cost for materials and labor, plus a pre-negotiated fee. This model offers maximum transparency, as the contractor usually provides all receipts.

- Fixed-Price (or Lump-Sum) Contract: The contractor provides a single, all-in price for the project. The material markup is bundled into that total, so you won't typically see individual receipts. This approach gives cost predictability but less insight into specific markups.

Open communication is what turns a transaction into a partnership. By openly discussing pricing and value, contractors and clients across the Bay Area can build the trust needed for success.

Your Partner for Predictable Project Costs

Getting a handle on your contractor markup on materials starts long before you draft a bid. It begins with a local supplier you can count on for accurate pricing, reliable inventory, and real-world advice. For builders, contractors, and architects across the Bay Area, Truitt & White is that partner.

Your relationship with your supplier is one of your biggest assets for keeping costs in check. When you have confidence in material pricing and availability, you can calculate your markups without guesswork. That trust translates into more stable and transparent pricing for your clients.

Building Confidence Through Reliability

We help bring predictability to your projects in a few key ways:

- Accurate and Timely Quotes: Our team delivers clear, detailed quotes so you have a solid cost basis to build from.

- Deep Local Inventory: We stock the materials that Bay Area projects demand, reducing the risk of last-minute substitutions or delays.

- Strong Manufacturer Relationships: We work closely with top brands to help smooth out price volatility and lock in the best possible costs.

This reliable foundation empowers you to create better budgets and build stronger client relationships. When costs are predictable, conversations about markups are simpler for everyone.

For total transparency, contractors can provide detailed financial models for projects that map out every expense. This allows clients to see exactly how material costs and markups fit into the bigger picture.

Our Commitment: We are a strategic partner invested in your success. Our goal is to give you the resources and support needed to keep your projects on track and on budget.

By ensuring you have access to premium materials and expert guidance, we help you deliver exceptional value to your clients. It's a partnership that solidifies your role as a trusted professional.

Ready to start your next project with confidence? Connect with our team today for expert advice and the reliable material solutions you need.

Frequently Asked Questions (FAQs) About Contractor Markups

Here are answers to some of the most common questions we hear from homeowners and contractors in the Bay Area about material markups.

1. Is it cheaper for me to buy my own materials?

Usually, the answer is no. Contractors receive trade discounts that are not available to the public. Even with their markup, the final price is often close to what you would pay at a retail store. Most importantly, the markup covers the contractor's service of ordering the correct materials, managing delivery, and handling any returns or damages, saving you time and preventing costly mistakes.

2. What is a typical material markup in the San Francisco Bay Area?

In the Bay Area, a material markup between 30% and 50% is a common and realistic range. This reflects our region’s higher operating costs for things like insurance, fuel, and labor. The final percentage will depend on the project's complexity, the type of materials being used, and the contractor's specific business overhead.

3. Can I ask my contractor to show me their receipts?

This depends on your contract type. In a Cost-Plus Contract, providing receipts is standard practice because you pay the actual costs plus a fee. However, in a Fixed-Price Contract, the contractor provides one total price for the entire project, and the markup is already included, so they are not obligated to show individual receipts.

4. Does a high markup mean I am being overcharged?

Not necessarily. A higher markup can often indicate a more professional and established business with higher overhead, such as comprehensive insurance, a dedicated team, and skilled project managers. In return, you often receive superior quality, better communication, and a solid warranty, so it's important to consider the total value the contractor provides.

5. How is a markup on materials different from a markup on labor?

Contractors apply different markups to materials and labor because they involve different risks and costs. Material markups are often higher to cover risks like supplier price increases, shipping damage, storage, and logistics. Labor markups are typically added to an employee's base pay to cover overhead costs like payroll taxes, workers' compensation insurance, benefits, and team management.

At Truitt & White, we believe clear communication and predictable costs are the bedrock of any successful project. We’re here to give Bay Area contractors the reliable material pricing and expert support they need to build with confidence.

Visit our Berkeley showroom or connect with our team for expert advice on your next project.