Pressure treated wood is standard lumber that has been infused with chemical preservatives to protect it from rot and insects. This is done in a high-pressure tank, which forces the protective chemicals deep into the wood's grain. For builders and homeowners in the Bay Area, it's a critical material for ensuring outdoor projects withstand our damp winters and local pests.

The entire purpose of this process is to dramatically extend the wood's lifespan, especially when it's used outdoors.

Understanding Pressure Treated Wood: The Basics

For builders, contractors, and homeowners across Berkeley and Oakland, pressure treated lumber is the backbone of durable outdoor construction. It's the material you can count on when building a deck with a view of the San Francisco Bay or a sturdy retaining wall in the Berkeley hills. The treatment process turns an ordinary piece of wood into a long-lasting, reliable building material.

This means you are investing in longevity and structural integrity right from the start. Standard untreated wood, when exposed to moisture and soil, can begin to decay in just a few years. Pressure treated wood, on the other hand, is engineered to last for decades.

Before we dive deeper, here's a quick summary.

Pressure Treated Wood At A Glance

This table breaks down the essentials of pressure treated wood into simple, easy-to-understand points.

| Core Aspect | Simple Explanation |

|---|---|

| What It Is | Standard wood (like pine or fir) infused with preservatives. |

| How It's Made | Placed in a tank, vacuum-sealed, then flooded with chemicals under high pressure. |

| Main Benefit | Highly resistant to rot, fungal decay, and wood-boring insects. |

| Best For | Outdoor projects like decks, fences, retaining walls, and playground equipment. |

| Lifespan | Can last for 20-40 years or more, depending on the conditions and treatment level. |

Essentially, it's your go-to lumber for anything that needs to hold up outside for the long haul.

Why It's a Go-To Building Material in the Bay Area

The benefits of using this specially treated lumber are clear, which is why it’s a favorite for both seasoned professionals and DIY remodelers. At its core, the value is all about its enhanced durability against common threats found right here in our local environment.

Here’s why it’s so essential for outdoor builds:

- Rot Resistance: The preservatives create a powerful barrier that stops fungi from breaking down the wood fibers—a critical feature in our often-damp Bay Area climate.

- Insect Protection: It effectively repels termites, carpenter ants, and other wood-boring insects that can seriously compromise a structure's safety.

- Cost-Effectiveness: While the upfront cost is higher than untreated wood, its long lifespan prevents expensive, time-consuming repairs and replacements, saving you money in the long run.

Choosing the right material is the first step toward a successful build. By understanding pressure treated wood, you can make informed decisions that ensure your work stands the test of time. You can explore a wide variety of quality lumber options in the East Bay to find the perfect fit for your next project.

The Pressure-Treatment Process Explained

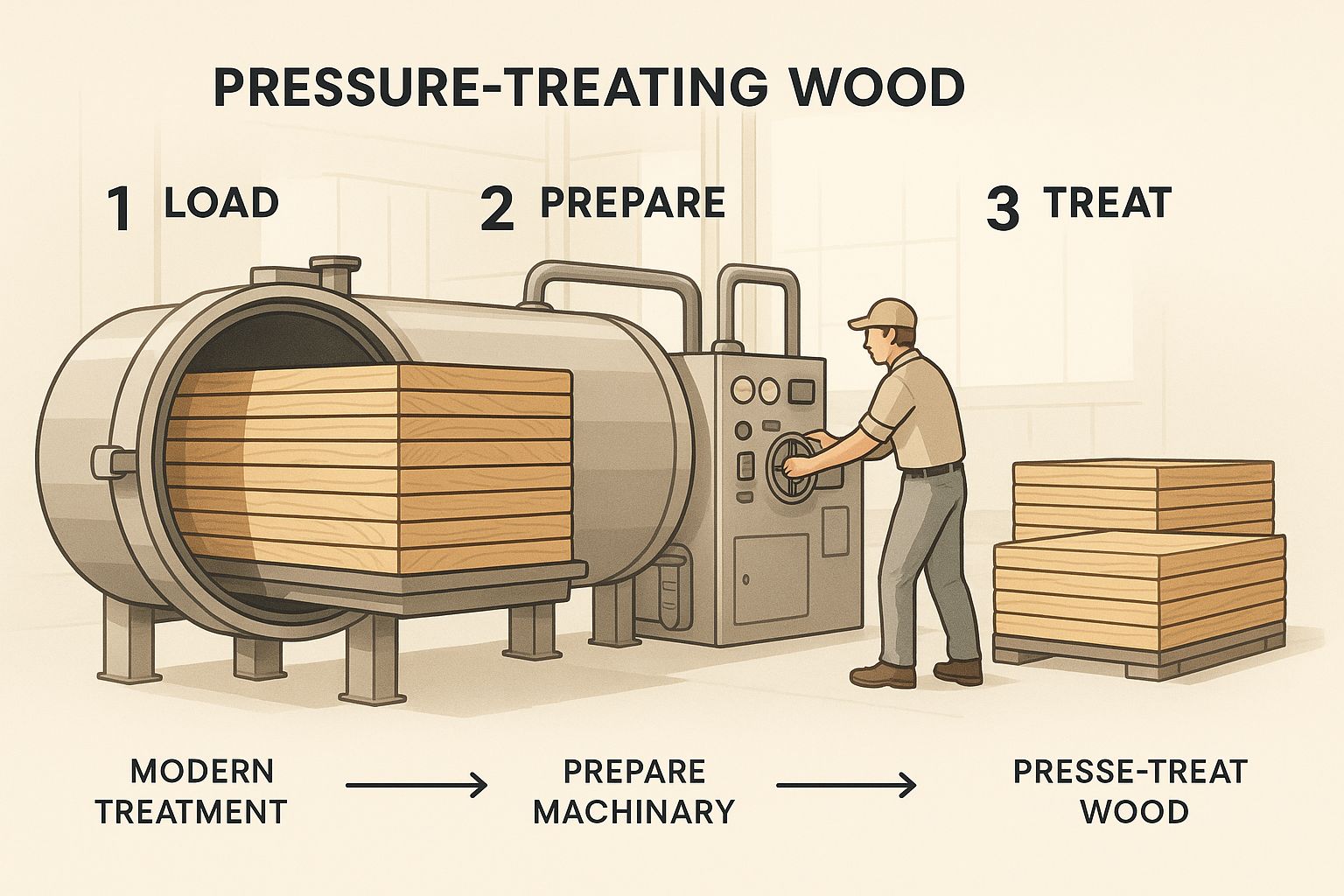

So, how does ordinary lumber transform into the durable, pressure-treated wood we rely on for decks, fences, and foundations? The process is a precise, industrial method that forces preservatives deep into the wood’s cellular structure, fortifying it from the inside out. This method is what gives the wood its strength to stand up to decay and insects for decades.

The key to the process is the combination of a vacuum and intense pressure. This duo forces protective preservatives far deeper into the wood fibers than any manual application ever could.

The Initial Vacuum Stage

The journey starts when stacks of standard lumber—often Southern Yellow Pine or Douglas Fir—are loaded into a massive, horizontal steel cylinder called a retort. After the heavy door is sealed airtight, a powerful vacuum pump removes all the air from the cylinder and, more importantly, from the microscopic cells within the wood itself.

This vacuum step is critical. By creating a void inside the wood's fibers, it prepares the lumber to act like a sponge, ready to soak up the preservative solution.

The Pressure and Saturation Phase

Once the vacuum is set, the retort is flooded with a liquid preservative solution. This is a carefully formulated mix of fungicides and insecticides designed to protect the wood. Most modern preservatives are copper-based compounds, which have a proven track record against both rot and pests.

With the cylinder full, powerful hydraulic pumps ramp up the pressure to incredible levels—often exceeding 150 pounds per square inch (psi). This intense pressure forces the chemical solution deep into the core of each board, ensuring complete saturation that leaves no part of the wood vulnerable.

This pressure-infusion method is what separates professionally treated lumber from wood that is merely sealed or painted. The protection is in the wood, not just on it.

Final Steps and Quality Control

After the wood has been under pressure for a set amount of time, the pressure is released, and the excess preservative solution is pumped out of the cylinder to be reused. A final vacuum is often applied to pull any remaining surface liquid from the wood. The freshly treated lumber is then removed and set aside to dry.

This sophisticated process gives wood its resistance to the forces that cause untreated wood to fail. When you understand the common causes of damp and rot in homes, you can appreciate why this internal protection is so vital. Choosing the right material always starts with knowing the differences between framing lumber grades and their specific treatment levels.

Decoding The Different Types Of Preservatives

Not all pressure treatments are created equal. The specific chemical preservative used is what gives the lumber its long-lasting strength, and today's formulas are safer and more effective than ever. Knowing the difference helps builders and homeowners in the Bay Area choose the right material for the job.

Modern Copper-Based Formulas

Today, almost all pressure-treated wood for residential use is treated with a copper-based preservative. Copper is a natural and highly effective fungicide and insecticide, making it the perfect main ingredient.

These modern formulas are a huge improvement over older, arsenic-based chemicals like Chromated Copper Arsenate (CCA), which were phased out for residential use in the early 2000s due to health concerns. As a result, today's products are safer for families while delivering exceptional performance. This shift aligns with the growing demand for eco-friendly construction materials.

When you visit a lumberyard near Oakland or Berkeley, you'll most likely find two common types:

- Alkaline Copper Quaternary (ACQ): One of the first widely adopted, arsenic-free alternatives. It combines copper with a quaternary ammonium compound for robust protection against rot and insects.

- Micronized Copper Azole (MCA): A newer, more advanced formula that uses microscopic copper particles suspended in the treatment solution. This technique allows for better penetration and results in a lighter, more natural wood color that’s easier to stain.

Why The Type Of Preservative Matters

The specific preservative used has practical implications for your project. For example, MCA-treated wood is generally less corrosive to fasteners than ACQ. Using the wrong fasteners can lead to corrosion that weakens the structure, so it's essential to use hot-dip galvanized or stainless steel screws with any modern treated wood.

Choosing the right preservative is about balancing performance, appearance, and the specific needs of your project. MCA’s less aggressive nature and lighter color have made it a popular choice for highly visible projects like decks and fences.

Copper-based preservatives now dominate the market for good reason. According to industry data, copper azole-treated wood can last 20 to 40 years, depending on its use. This shift ensures modern building practices are both durable and responsible.

Choosing The Right Treatment Level For Your Bay Area Project

Using a piece of lumber meant for a fence panel where it's going to be buried in the ground is a recipe for premature failure. To avoid this, the industry developed a straightforward rating system to match the wood to its intended use.

This system, known as the Use Category (UC) system from the American Wood Protection Association (AWPA), classifies treated wood based on the level of exposure it can handle. Understanding these categories is key to ensuring your project lasts for decades and meets local Bay Area building codes.

Understanding The Use Category System

Think of Use Categories like SPF ratings for sunscreen. Each level offers a specific degree of protection for a particular situation. A lower UC number is for milder conditions, while a higher number means the wood is tough enough for harsh environments.

Here’s a quick rundown of the common categories you'll see on projects in Berkeley, Oakland, and across the region:

- UC1 & UC2 (Interior Use): For interior work only, in areas that are kept dry. You won't use these for outdoor projects.

- UC3B (Exterior Above-Ground): This is your go-to for most exterior projects that do not touch the ground. It’s perfect for deck boards, railings, and fence pickets.

- UC4A (Ground-Contact): This is a non-negotiable category for any wood that will be in direct contact with the ground or fresh water. Use this for fence posts and deck support posts.

- UC4B (Heavy-Duty Ground-Contact): When conditions are tough, this category provides a higher preservative level for critical structural pieces like foundation posts.

To make this even clearer, we've put together a simple guide.

A Simple Guide To Wood Use Categories

This table offers a clear comparison of AWPA Use Categories, helping you select the correct lumber for your project's specific needs and exposure levels.

| Use Category | Common Environment | Typical Bay Area Projects |

|---|---|---|

| UC3B | Above ground, exposed to weather, easily sheds water | Decking, railings, fence pickets, fascia, trim, trellises, pergolas |

| UC4A | In the ground, in fresh water, or in other critical applications | Deck posts, fence posts, retaining walls, garden bed frames |

| UC4B | In the ground in very harsh conditions (high moisture, decay risk) | Permanent wood foundations, utility poles, critical structural posts |

Knowing these distinctions is what separates a project that lasts from one that needs repairs in a few years.

Matching The Wood To The Job

Let's apply this to a real-world Bay Area project. Imagine you're building a new deck overlooking the San Francisco Bay. The beautiful redwood or composite deck boards you'll walk on only need a UC3B-rated substructure because they're elevated with good airflow.

But the support posts holding that deck up? Those must be rated UC4A for ground contact, period. Those posts are buried in damp soil and are prime targets for rot if not properly treated. Using a lower-rated wood here would compromise the safety of the entire deck, a detail covered in our deck planning guide.

The rule is simple: if the wood touches the ground or is critical to the structure's stability, you must use a ground-contact rated product (UC4A or higher). Cutting corners here is never worth the risk.

Common Uses for Pressure Treated Wood in Construction

From backyard decks in the East Bay hills to the foundational elements of a new home, pressure treated wood is the workhorse of outdoor construction. Its ability to stand up to moisture and insects is why builders rely on it. This is about building structures that are safe, stable, and durable for years to come.

The purpose of pressure treated wood is longevity where it counts. The global treated wood market continues to grow, reflecting its importance in modern construction.

Decks And Fences

Walk onto almost any deck, and you're standing on a pressure treated substructure. For a properly built deck, the entire substructure—joists, beams, and support posts—should be made from ground-contact rated (UC4A) treated wood. The parts you walk on, like the decking and railings, can use an above-ground rating (UC3B).

It’s the same story with fences. The posts must be rated for ground contact because the most common point of failure is where the post meets the soil. Get that part right, and the fence pickets and rails can be built with above-ground rated lumber.

Retaining Walls And Landscaping

Any project where wood will be in constant contact with the soil demands the strength of treated lumber.

- Retaining Walls: To hold back soil, you need timbers that can handle constant moisture pressure. That's a job for treated wood.

- Garden Beds: Raised garden beds built with modern, copper-based treated wood are safe for growing vegetables and will outlast untreated lumber by years.

- Playground Equipment: When it comes to swing sets and play structures, safety is everything. Treated wood is the standard for a reason.

The rule of thumb is simple: if the wood touches the ground or will be constantly wet, it has to be pressure treated.

Structural And Foundational Uses

Treated wood also plays a vital, often unseen, role in a home's structural health. The sill plates—the first piece of lumber that sits on top of a concrete foundation—must be pressure treated.

This creates a crucial barrier, preventing moisture from wicking up from the concrete and rotting the home’s framing from the bottom up. It’s a small detail that protects the entire house.

How to Safely Work With Pressure-Treated Wood

Whether you're a seasoned contractor or a weekend DIYer, handling pressure-treated wood correctly is crucial for safety. While modern preservatives are far safer than their predecessors, you should still take proper precautions.

Following a few simple guidelines will keep everyone on the job site protected.

Personal Protective Equipment (PPE)

When cutting, sanding, or drilling pressure-treated wood, you need to wear the right personal protective equipment (PPE). The sawdust can carry chemical residue, and you don't want to breathe it in or get it in your eyes.

Your essential safety kit should include:

- Gloves: Heavy-duty work gloves protect your hands from splinters and minimize skin contact with preservatives.

- Safety Glasses: Shield your eyes from flying debris and sawdust at all times.

- Dust Mask: A NIOSH-approved respirator or quality dust mask is critical to prevent inhaling treated sawdust particles.

Critical Handling and Disposal Rules

Beyond PPE, a couple of rules are absolute. First, never burn pressure-treated wood scraps. Burning this wood releases preservative chemicals into the air as toxic fumes. Always dispose of scraps with your regular construction debris, following local Berkeley and Alameda County regulations.

Second, you must use the right fasteners. The high copper content in modern treated wood will corrode standard steel screws and nails. You must use hot-dip galvanized or stainless steel fasteners to prevent structural failure.

It's always smart to assess potential chemical exposure when working with treated materials. For a bigger-picture view, a thorough construction safety checklist can help keep your entire Bay Area project secure.

Frequently Asked Questions About Pressure Treated Wood

Here are straightforward answers to the most common questions we hear from builders, contractors, and DIYers around the Bay Area.

When Can I Paint Or Stain New Pressure Treated Wood?

You must wait for the wood to dry out completely before applying any paint or stain. This can take anywhere from a few weeks to several months, depending on our Bay Area weather. A simple trick is to sprinkle a few drops of water on the surface; if the water soaks in, you're good to go.

Is Pressure Treated Wood Safe For A Garden Bed?

Yes, the pressure treated wood you'll find today is safe for garden beds. Modern preservatives, like Micronized Copper Azole (MCA), are approved by the EPA for residential use and don't contain arsenic. You can add a plastic liner to the inside of the bed for extra peace of mind.

How Long Will My Pressure Treated Wood Deck Last?

In our local climate, a well-built deck using the right lumber can easily last 40 years or more. The two biggest factors are proper installation and using ground-contact rated wood (UC4A) for any posts or joists that touch the soil. Regular cleaning and sealing will also extend its life.

What Kind Of Screws Should I Use With Treated Wood?

This is critical: always use hot-dip galvanized or stainless steel fasteners. The high copper content in today's treated wood is corrosive and will destroy standard steel screws and nails. Using the right hardware is non-negotiable for the long-term safety of your structure.

Why Does New Treated Lumber Sometimes Look Warped Or Wet?

It's normal for a fresh batch of pressure treated lumber to feel damp and heavy. The treatment process forces a water-based preservative deep into the wood's fibers. As this moisture evaporates, the wood naturally shrinks, which can sometimes cause minor warping or small surface cracks known as "checking."

At Truitt & White, we don’t just sell lumber; we provide the high-quality materials and expert advice that ensure your Bay Area project stands the test of time. Visit our Berkeley showroom or connect with our team for personalized guidance on your next build.