For most home projects in the Bay Area, there's a clear winner for the best plywood for subflooring: CDX tongue-and-groove (T&G) panels. The "CDX" grade offers the strength and moisture resistance you need. The T&G design locks the panels together, creating a solid floor that helps prevent squeaks.

Why Quality Subflooring Matters in the Bay Area

Think of your subfloor as the foundation for your floors. It’s the strong, flat layer that supports everything from hardwood to tile. For anyone building or remodeling in Berkeley, Oakland, or San Francisco, getting the subfloor right is critical.

Our Bay Area climate, with its fog and humidity, puts stress on a home’s structure. A weak subfloor can lead to major problems down the road.

Cutting corners on subflooring can cause future headaches. Common issues include:

- Squeaks and creaks as boards shift and rub together.

- Floors that sag or feel uneven underfoot.

- Moisture damage, like rot, that can harm the home's structure.

- A shorter lifespan for expensive flooring like hardwood or tile.

Choosing the right subfloor material is an investment in your home’s long-term health. According to Allied Market Research, the global plywood market was valued at $54.2 billion in 2022, and it continues to grow as a key building material.

| Key Subfloor Functions | Impact on Bay Area Homes |

|---|---|

| Structural Support | Adds needed stiffness between floor joists, important for seismic stability. |

| Moisture Barrier | Resists dampness from fog and rain common during construction phases. |

| Level Surface | Creates a smooth, flat base for a professional flooring installation. |

By choosing the best plywood, you build a reliable foundation that protects your floors for years. For more tips on building materials, see our guide to quality lumber in the East Bay.

How to Read Plywood Grades for Subfloors

When choosing plywood, the letters stamped on the panel tell you its quality. For builders and homeowners in Berkeley, understanding these grades ensures you get the right product. This leads to a solid, quiet floor that lasts.

The most common letters are A, B, C, and D. They grade the wood veneer on the front and back. Think of it like a report card: 'A' is the best and smooth, while 'D' allows for more knots and flaws.

Understanding Veneer Grades

A subfloor gets covered, so you don't need a perfect 'A' grade finish. That's why 'C' and 'D' grades are the standard for structural work like subfloors.

Here’s a quick guide to what the letters mean:

- A-Grade: Smooth and paintable. Not needed for a subfloor.

- B-Grade: Solid surface with minor splits or tight knots.

- C-Grade: Your typical subfloor face. It can have knots up to 1.5 inches and some discoloration.

- D-Grade: Often the back side. It can have larger knots and knotholes up to 2.5 inches.

A panel stamped "CD" has a C-grade face and a D-grade back. It’s a practical choice that provides strength without paying for looks that will be hidden.

What Does CDX Plywood Mean?

For Bay Area subflooring, CDX is the term you'll hear most. We know "CD" refers to the veneer grades, but the "X" is also very important. It stands for exposure, meaning the panel is bonded with a water-resistant adhesive.

This is a big deal during construction in Oakland or San Francisco, where fog or rain can get materials damp. The 'X' means the panel can handle some moisture without delaminating, or falling apart.

Key Takeaway: The "X" in CDX does not mean the plywood is waterproof. It is water-resistant for temporary exposure during construction. Always let it dry completely before installing finished flooring.

Contractors should also know the difference between standard panels and tongue-and-groove (T&G) panels. T&G panels interlock, creating a much stiffer floor that is less likely to squeak. Understanding these features, much like knowing different framing lumber grades, is key to quality construction.

Comparing Plywood Options for Your Subfloor

Choosing the right subfloor plywood is a key decision that impacts a home for years. It’s about creating a solid, quiet, and durable base. For builders in the Bay Area, the choice often comes down to a few proven options.

Let's compare the main contenders: CDX, Tongue-and-Groove (T&G), and BC-Grade plywood. We’ll look at what matters most on a local job site, from moisture resistance to stability.

Moisture Resistance and Durability

Those foggy Berkeley and Oakland mornings can expose a subfloor to a lot of damp air. Moisture resistance is a top priority.

- CDX Plywood: This is the workhorse for subflooring. The "X" in CDX means it has an exterior-grade adhesive. It can resist delamination if it gets wet during construction and dries out well.

- BC-Grade Plywood: This plywood usually has interior glue. It's not a good choice for a subfloor that might get exposed to weather.

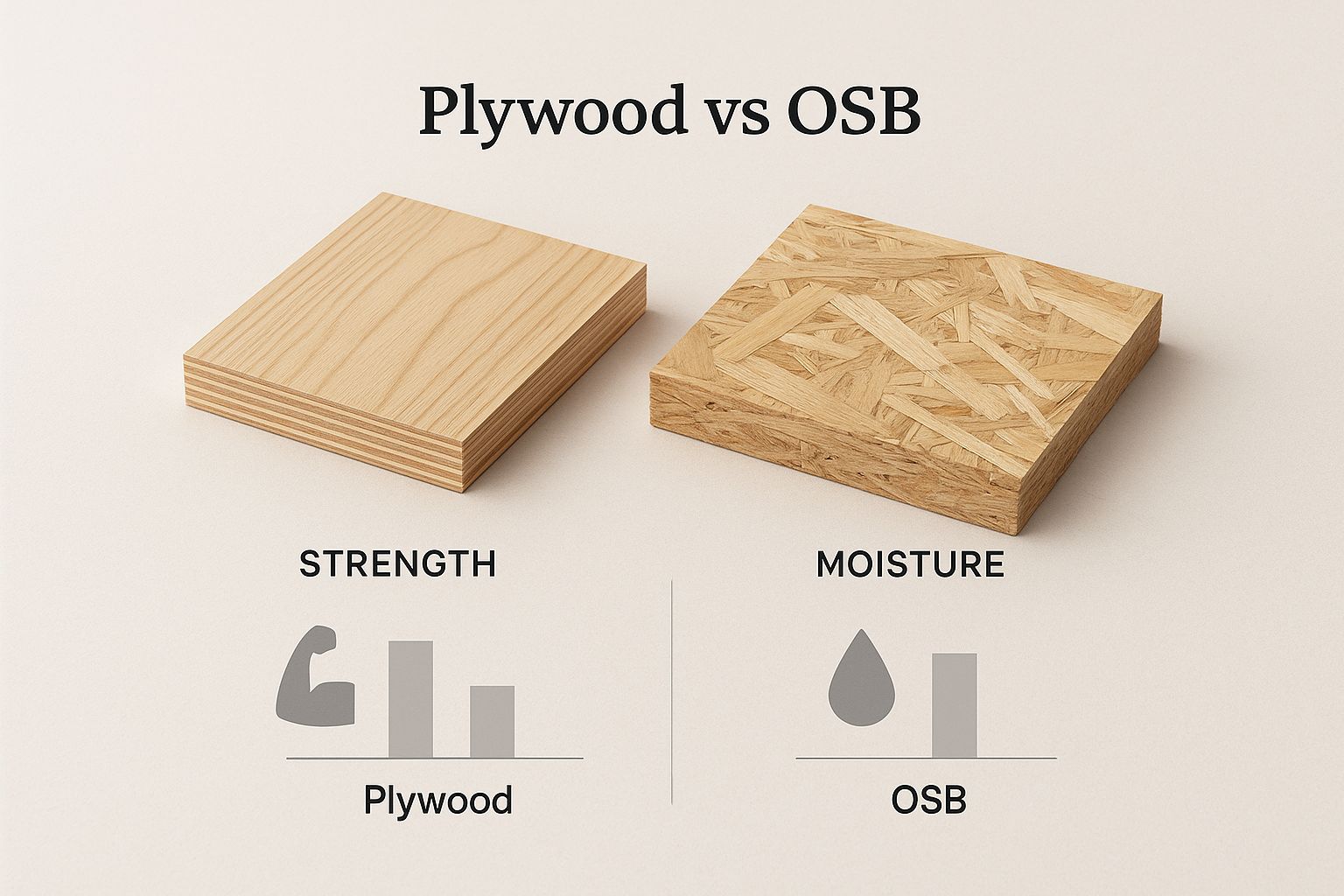

The image below shows how plywood compares to another common material, OSB, when dealing with moisture.

Plywood’s layered design gives it an advantage in strength and handling moisture. This is why it remains the top choice for professionals building a lasting subfloor.

Structural Stability and Installation

A subfloor’s main job is to be a flat, stable foundation. The way panels connect is a huge factor.

This is where Tongue-and-Groove (T&G) plywood stands out. The interlocking edges force the panels to act as one solid surface. This distributes weight evenly and greatly reduces the chance of squeaks.

Expert Insight: For projects with wider joist spacing or in high-traffic areas, T&G is a must. The interlocking system helps eliminate the panel movement that causes floor squeaks.

Standard CDX panels have square edges. They are faster to install, but you need to add support blocking along seams that don't land on a joist. If you want to learn more about advanced materials, our guide on what engineered wood is is a great place to start.

Cost-Effectiveness and Final Recommendation

So, which plywood is best for your project? It depends on your budget and goals.

Subflooring Plywood Comparison for Bay Area Projects

This table gives a quick overview of how the top choices perform in the Bay Area.

| Evaluation Criteria | CDX Plywood | Tongue & Groove (T&G) Plywood | BC-Grade Plywood |

|---|---|---|---|

| Moisture Resistance | Good (Exterior Glue) | Excellent (Exterior Glue) | Poor (Interior Glue) |

| Structural Stability | Good | Excellent (Interlocking) | Good |

| Squeak Prevention | Fair | Excellent | Fair |

| Best Use Case | Budget-conscious standard builds | High-performance, squeak-free floors | Interior projects (not subfloors) |

| Cost | $ | $$ | $$ |

For most projects in the Bay Area, T&G plywood is our top recommendation. Its strength and squeak prevention offer the best long-term value. Standard CDX is still a solid choice for projects where budget is the main concern.

Selecting The Right Plywood Thickness

Choosing the right subfloor plywood is not just about the grade. The panel’s thickness is key for stiffness and performance. Using the wrong thickness can lead to a bouncy or sagging floor.

Joist spacing is the biggest factor in deciding thickness. Wider joist spacing requires thicker plywood to carry the load without bending.

Common Thickness Standards For Joist Spacing

Here’s a quick reference for common residential joist layouts:

| Joist Spacing | Minimum Thickness | Preferred Upgrade |

|---|---|---|

| 16 inches on center | 19/32-inch (5/8-inch) plywood | 23/32-inch (3/4-inch) |

| 24 inches on center | 23/32-inch (3/4-inch) plywood | – |

A slightly thicker panel provides better rigidity, especially under heavy materials like tile.

Pro Tip for Bay Area Contractors: In seismic zones like ours, consider using 23/32-inch panels even at 16-inch spacing. The extra stiffness helps the entire floor system resist movement.

The Strength Of Softwood Plywood

Structural subfloors are almost always made of softwood plywood from trees like Douglas fir or pine. These woods offer a great strength-to-weight ratio.

According to Allied Market Research, softwood plywood made up over 74% of the global plywood market in 2022. For more details on this trend, see the report on the dominance of softwood plywood in construction.

Matching the right grade (CDX with T&G) and thickness creates a subfloor that feels solid and protects your finished floors.

Installation Tips for a Squeak-Free Subfloor

Even the best plywood can fail if not installed correctly. A proper installation creates a stiff, quiet, and long-lasting floor. For builders in the Bay Area, a few key steps make all the difference.

First, give the panels room to breathe. Wood expands and contracts with humidity changes. Always leave a 1/8-inch gap between panel edges and a 1/4-inch gap at the walls to prevent buckling.

Proper Fastening and Adhesion

Securing the panels correctly is just as important as spacing. Combining construction adhesive with the right fasteners creates a super-strong bond.

- Apply Construction Adhesive: Before laying a panel, run a continuous bead of subfloor adhesive along the top of each joist. This glues the plywood to the frame and stops the small movements that cause squeaks.

- Follow a Fastening Schedule: Use the correct screw or nail size for your panel thickness. Place fasteners every 6 inches along panel edges and every 12 inches in the middle of the panel.

Expert Insight: For the best results, always glue and screw the subfloor. Screws have better holding power than nails and won't back out over time, keeping your floor tight and silent.

For homeowners, addressing subfloor integrity during comprehensive floor restoration is essential for a successful project. A solid subfloor ensures your new floors look great and last long.

Acclimate Your Materials

Finally, let your materials adjust to the site. Allow your plywood panels to sit in the room where they will be installed for at least 48-72 hours. This lets the wood's moisture content match the home's environment, reducing the risk of swelling or shrinking later.

Using quality materials with careful installation and proper fasteners builds a foundation that lasts. To finish the job right, check out fastening solutions from Sure Drive USA, available in Berkeley.

Your Bay Area Subflooring Partner

Once you know which plywood you need, the next step is finding the right materials. At Truitt & White, we stock high-quality subflooring products, from standard CDX panels to premium tongue-and-groove options.

What We Offer

Our inventory focuses on what pros trust and use on the job.

- CDX Plywood: A reliable choice for its strength and moisture resistance.

- Tongue-and-Groove Panels: The best option for a solid, squeak-free floor.

- BC-Grade Options: Great for interior projects needing a cleaner finish.

Our team has experience with all types of Bay Area projects. Whether you're remodeling a classic Berkeley home or building new in Oakland, we can help you choose the right materials. We know local building codes and what works best in our climate.

If you need help finding a professional for your project, our guide on how to choose a contractor is a great resource to get started.

Frequently Asked Questions (FAQs)

What is the best plywood for a subfloor?

For most residential projects, 23/32-inch (commonly called 3/4-inch) tongue-and-groove CDX plywood is the best choice. It offers excellent strength, moisture resistance, and the interlocking edges help prevent squeaks. This makes it ideal for the demands of Bay Area construction.

Should I use OSB or plywood for a subfloor?

While OSB is often cheaper, plywood is generally stronger and handles moisture better. Plywood is less likely to swell at the edges if it gets wet during construction. For the humid Bay Area climate, plywood’s durability makes it the more reliable option.

What does the 'X' in CDX plywood mean?

The 'X' in CDX stands for "exposure." It means the plywood was made with an exterior-grade, water-resistant glue. This allows it to handle temporary exposure to rain or fog during construction without falling apart, though it is not fully waterproof.

Do I really need tongue and groove plywood?

We highly recommend it. Tongue and groove (T&G) panels interlock to create a single, solid surface that distributes weight evenly. This design is the most effective way to prevent the panel movement that causes annoying floor squeaks later on.

What thickness plywood should I use for a subfloor?

The right thickness depends on your floor joist spacing. For joists spaced 16 inches apart, 19/32-inch plywood is the minimum, but 23/32-inch is better. If your joists are 24 inches apart, you should always use 23/32-inch (3/4-inch) plywood for proper support.

For expert advice and to find the best plywood for subflooring for your Bay Area project, trust the team at Truitt & White. Visit our Berkeley showroom or contact us today for quality materials and professional guidance.