In the busy world of Bay Area construction, safety is the foundation of every good project. This is true for big projects in San Francisco and home builds in Berkeley. For builders and contractors, a construction safety checklist is the best tool for managing risks on the job site. It turns complex rules from OSHA and California into a simple, daily routine.

A good checklist helps your team find dangers before they cause accidents. It protects your workers, your most important asset. It also protects your business from expensive delays and legal trouble. According to the U.S. Bureau of Labor Statistics, construction has one of the highest injury rates, so safety rules are a must.

This guide gives you a detailed construction safety checklist made for Bay Area job sites. We will cover seven key areas of on-site safety with clear steps. This will help you build a safer and more efficient project from the ground up.

1. Personal Protective Equipment (PPE) Compliance

Personal Protective Equipment (PPE) is your first line of defense against injuries. A PPE check ensures every worker has the right safety gear before starting work. This is a key part of any construction safety checklist and a rule from the Occupational Safety and Health Administration (OSHA).

This means more than just having gear nearby. It means checking daily that everyone is wearing the correct equipment for their job. Properly worn PPE prevents accidents and makes any that do happen less serious.

Why PPE Compliance is Essential

Good PPE programs create a strong safety culture. They protect your workers and your business. Enforcing PPE rules shows everyone that safety is the top priority, which reduces accidents and project delays.

A simple "no PPE, no work" rule is very effective. It makes it clear that safety rules are not optional.

For example, Turner Construction started using a digital system to track PPE. This led to 40% fewer safety incidents. This shows that checking for PPE leads to better safety.

Actionable Tips for Enforcing PPE Compliance

Making sure everyone wears PPE takes clear communication and daily effort. The goal is to make wearing PPE a habit for everyone on site.

- Hold Daily Toolbox Talks: Start each day with a short meeting. Talk about the PPE needed for the day’s tasks and check that everyone is wearing it.

- Use Visual Checklists: Post simple checklists with pictures at site entrances. This helps supervisors do quick checks during the day.

- Offer Choices: Provide a few approved options for gear like gloves or safety glasses. People are more likely to wear gear they find comfortable.

- Lead by Example: All managers and visitors must follow the same PPE rules. When leaders follow the rules, the whole crew will too.

2. Fall Protection Systems Verification

Checking fall protection systems is a must for any work done at heights of 6 feet or more. This means checking guardrails, safety nets, and personal fall harnesses. Falls are the top cause of death in construction, so this part of your construction safety checklist needs daily attention.

This check is more than a quick look. It's a careful inspection to make sure all gear is installed right, has no damage, and meets OSHA standards. Good fall protection saves lives and prevents big project delays.

Why Fall Protection Verification is Crucial

A strong fall protection program makes the worksite feel secure. It directly addresses the biggest risk in the industry. When every harness and guardrail is checked, the chance of a serious accident is much lower.

Always "trust but verify" your fall protection. Never assume gear is safe just because it was used yesterday. Daily checks make this a habit.

For instance, Mortenson Construction started a new fall protection training program. It led to a 75% drop in fall-related accidents. This shows that focusing on equipment checks and training makes job sites much safer.

Actionable Tips for Verifying Fall Protection Systems

A good fall protection program needs careful planning and clear rules. The goal is to make sure every piece of equipment is ready before a worker is at risk of falling.

- Assign a Competent Person: Choose a team member who is trained to inspect fall protection gear. This person should lead daily checks and approve all systems.

- Document Weekly Inspections: In addition to daily checks, do a more detailed inspection of all fall gear once a week. Keep a record to track wear and tear over time.

- Create a Rescue Plan: Before work starts at a high level, make a clear rescue plan. Make sure the crew knows what to do if someone falls.

- Enforce a 100% Tie-Off Rule: Require any worker using a fall arrest system to always be connected to an anchor point. This prevents falls when moving between anchors.

3. Electrical Safety and Lockout/Tagout (LOTO)

Electrical dangers on a construction site can be deadly. A Lockout/Tagout (LOTO) procedure is a way to control dangerous energy. This vital part of your construction safety checklist makes sure electrical equipment is turned off and cannot be turned back on during repair work.

LOTO is more than flipping a switch. It involves putting a lock and tag on the power source. This tells others that the equipment is being serviced and should not be used. OSHA data shows that electrocution is a leading cause of death in construction.

Why LOTO Procedures Are Essential

A strict LOTO program is the only way to be sure there is no electrical power before work starts. It makes safety a certainty, not a guess. This protects workers from surprise startups or shocks.

Always test to confirm the power is off before touching a circuit. This leaves no room for mistakes.

For example, PCL Construction uses a digital LOTO system. This helps track every lockout, which reduces human error. Making LOTO a firm rule helps prevent terrible accidents.

Actionable Tips for Enforcing Electrical Safety

Creating a culture of electrical safety requires clear rules and good training. The goal is to make these life-saving steps a habit for everyone.

- Use Formal LOTO Training: Only trained and authorized workers should perform LOTO. Make sure this training is recorded and updated each year.

- Test All GFCIs: All temporary power outlets should use a Ground Fault Circuit Interrupter (GFCI). Test them every month to make sure they work.

- Keep a Safe Distance: Keep workers and equipment at least 10 feet away from overhead power lines. Use signs and spotters to prevent contact.

- Use Group Lockout for Team Jobs: When many workers are on one piece of equipment, use a group lockout box. The power cannot be turned on until every worker has removed their lock.

4. Heavy Equipment and Vehicle Safety

Safety rules for heavy equipment are needed to manage big hazards on a job site. This means having a clear plan for using and checking all machinery, like excavators and cranes. These checks are a key part of your construction safety checklist and help prevent "struck-by" accidents, a top cause of death in construction.

Good management requires daily equipment checks and clear communication. It also means setting up safe work zones. By having a safety process for every machine, you lower the risk for everyone on site.

Why Heavy Equipment Safety is Essential

A mistake with heavy equipment can cause serious harm right away. Strict rules protect workers and prevent expensive equipment damage. When everyone knows and follows the rules for machines, the job site is much safer.

A clear traffic plan for vehicles and people is not a suggestion. It's a system for preventing accidents.

For example, many sites now use new technology to reduce human error. Caterpillar's Command system uses autonomous trucks to make hauling safer. This shows how strict procedures and technology can make equipment operation safer.

Actionable Tips for Enforcing Equipment Safety

A strong equipment safety program needs clear rules and constant attention. The goal is to make safe operation a habit for everyone.

- Do Daily Circle Checks: Before starting a machine, operators must walk around it to inspect it. Following detailed pre-trip inspection procedures is a key step to keeping the site safe.

- Set Up Safe Zones: Use barriers and cones to mark "no-go" zones around equipment. Train all workers to keep a safe distance and make eye contact with the operator before getting close.

- Use Standard Signals: Have a single set of hand signals and radio rules for all operators and spotters. This prevents confusion in noisy areas.

- Use Lockout/Tagout (LOTO) for Repairs: During maintenance, all equipment must be turned off and locked out. This prevents it from starting by accident and hurting mechanics.

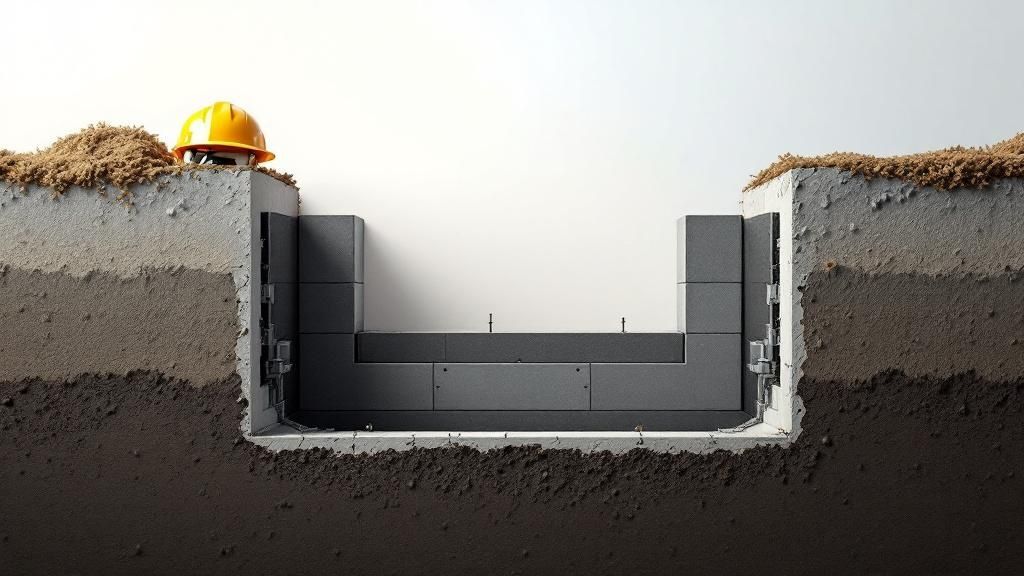

5. Excavation and Trenching Safety

Digging trenches is one of the most dangerous jobs in construction because they can collapse suddenly. A good safety plan is a vital part of any construction safety checklist. It focuses on protecting workers before they go into a trench. This means checking the soil and using protective systems like trench boxes.

This process is more than just digging. It needs a "competent person" to check excavations every day. This person looks for dangers and makes sure protective gear is used correctly. Good trenching safety prevents collapses, which can happen in seconds.

Why Excavation Safety is Essential

One cubic yard of soil can weigh as much as a car, making an unprotected trench a death trap. Strict safety rules save lives and prevent big project delays and fines. A well-managed dig site shows that a company is professional and cares about safety.

The most dangerous trench is often the one that looks safe. Soil can become unstable quickly, which is why protective systems are required by law.

For example, companies that use modern trench boxes or shoring systems greatly reduce the risk of a collapse. These engineered solutions provide reliable protection and keep workers safe.

Actionable Tips for Enforcing Excavation Safety

A good excavation safety plan has clear rules that are always followed. The goal is to remove the risks of working underground through careful planning.

- Never Enter Unprotected Trenches: No worker should ever enter a trench deeper than five feet without a protective system. This includes shoring, shielding, or sloping the trench walls.

- Keep Soil Piles Away: Keep dug-up soil and other materials at least two feet from the edge of a trench. This stops it from falling back on workers.

- Provide Safe Ways In and Out: Use ladders or ramps every 25 feet in trenches that are four feet or deeper.

- Inspect Daily: A competent person must check trenches every day and after any event like a rainstorm. They look for signs of a possible collapse.

6. Hazardous Materials Handling and Storage

Properly managing hazardous materials is a key part of any construction safety checklist. This means correctly identifying, handling, and storing dangerous substances like fuels and chemicals. Good hazmat management is required by the EPA and OSHA to prevent fires, toxic exposure, and pollution.

A good hazmat plan makes sure every chemical on site is accounted for. It also ensures every worker knows how to handle it safely. This includes making sure containers are labeled right and having spill kits ready.

Why Hazmat Management is Essential

A good plan for hazardous materials protects your team and your business. When hazmat rules are followed, the risk of accidents that can cause serious injuries or costly cleanups is much lower. This is key for keeping projects on schedule.

Treat every chemical container with respect, from a spray can to a fuel drum. Proper storage is not optional.

For example, top chemical companies like Dow have created strict site rules that are now used across the industry. By using clear labels and training, they greatly reduce chemical-related accidents.

Actionable Tips for Enforcing Hazmat Compliance

A successful hazmat program needs clear communication and strict rules. The goal is to make safe handling a normal part of daily work.

- Keep Safety Data Sheets (SDS) Updated: Have a file of the SDS for every hazardous substance on site. Make sure workers know where to find it and how to read it.

- Use Secondary Containment: Store liquid chemicals in areas with spill pallets or barriers. This will catch any leaks and stop them from spreading.

- Provide Specific Training: Train workers on the specific dangers of the chemicals they use. This should cover proper handling and what to do in an emergency.

- Check Inventory Regularly: Do regular checks of all stored materials. Look for damaged containers and make sure everything is labeled correctly.

7. Scaffolding and Temporary Structure Safety

Checking scaffolding and other temporary structures is key to keeping elevated work areas safe. These structures are common in construction but can lead to falls and collapses if not built right. A strict inspection plan is a must-have on any construction safety checklist for work done at a height.

This process requires daily checks by a competent person. They look for problems like loose parts or missing guardrails before they cause an accident. Proper scaffolding safety protects everyone on the job site.

Why Scaffolding Integrity is Critical

Unsafe scaffolding is a huge risk to workers on the platform and below. Following strict assembly and inspection rules is key to preventing falls. A secure platform helps workers feel confident and keeps the project moving.

A scaffold is only as safe as its last inspection. Treat it like a permanent structure that needs daily checks.

Companies like Safway Group make advanced scaffold systems with built-in safety features. But these are only effective if they are put together correctly. Following the manufacturer's rules and OSHA standards makes these structures a safe place to work.

Actionable Tips for Safe Scaffolding

A good scaffolding plan includes proper building, regular checks, and safe use rules.

- Inspect Before Every Shift: A competent person must check scaffolds for any damage before each work shift.

- Ensure a Solid Foundation: Scaffolds must be built on stable, level ground. Use base plates to spread the load, especially on soil or asphalt.

- Verify Fall Protection: OSHA requires guardrails on any scaffold 10 feet or higher. Make sure top rails, mid-rails, and toeboards are installed correctly.

- Maintain Proper Access: Provide safe access to all scaffold platforms, like ladders or stairs. Do not let workers climb on the cross-braces.

From Checklist to Culture: Making Safety Your Competitive Advantage

A good construction safety checklist shows that true safety is more than just a document. It is an active commitment that is part of every project. Going beyond just following rules from agencies like OSHA and building a real safety culture is what makes a great contractor. This checklist gives you the framework to do that.

When your team makes these safety rules a habit, the checklist becomes a tool that empowers them. Checking fall protection, using LOTO procedures, and watching heavy equipment become normal habits that protect your people. This change improves morale, reduces delays, and builds your reputation in the competitive Bay Area market.

Key Takeaways for Building a Safer Job Site

Using a construction safety checklist is about building a strong and respected business. Here are the main ideas to remember:

- Consistency is Critical: Daily safety checks and constant rule enforcement create a safe and predictable job site.

- Be Proactive, Not Reactive: Find and fix dangers before they can cause harm.

- Training is an Investment: A well-trained crew is your best defense against accidents.

Actionable Next Steps: Turning Knowledge into Practice

Understanding the checklist is the first step. Using it is what makes a difference. Here is how to put these ideas into action:

- Digitize Your Checklist: Use a digital app to create a custom construction safety checklist for your project, whether it's a remodel in Berkeley or a build in Oakland.

- Start a "Safety Huddle" Program: Begin each day with a short meeting to talk about the day's tasks and any potential dangers.

- Invest in Modern Training: Consider using new training methods to build a stronger safety culture. Some companies use virtual reality to simulate dangerous situations safely. According to AIDAR Solutions, these Virtual Reality Training Solutions That Drive Results can help workers remember and use safety knowledge on the job.

- Conduct Surprise Audits: Have a supervisor do surprise walk-throughs using the checklist. This makes sure safety standards are followed all the time.

By using these practices, your construction safety checklist becomes a tool for getting better every day. It becomes the foundation of a culture where everyone feels responsible for site safety. This protects your crew and builds trust with clients, architects, and the community.

A safe job site starts with reliable materials and expert support. For nearly 80 years, Truitt and White has been the Bay Area's trusted partner for high-quality lumber, tools, and building supplies that meet the industry's highest safety and performance standards. Visit our Berkeley showroom for expert advice. You can connect with us here.

Frequently Asked Questions (FAQs)

1. What is the most important item on a construction safety checklist?

While all items are critical, verifying fall protection systems is often considered the most important. This is because falls are consistently the leading cause of fatalities in the construction industry, according to OSHA.

2. How often should I conduct safety checks on a Bay Area job site?

Key safety checks, like inspecting PPE, scaffolding, and excavations, should be done daily before work begins. More detailed inspections of equipment should happen weekly, and all checks should be documented.

3. Who is responsible for enforcing the safety checklist on site?

The site supervisor or project manager is ultimately responsible. However, a strong safety culture makes every crew member feel responsible for their own safety and for watching out for their coworkers.

4. Can a single checklist be used for all types of construction projects?

A general checklist is a good starting point, but it should be customized for each project. A home remodel in Oakland will have different specific risks than a commercial build in San Francisco, so the checklist should reflect that.

5. How does a safety checklist help with Cal/OSHA compliance?

A well-maintained checklist provides documented proof that you are actively identifying and correcting hazards. This is a core requirement of Cal/OSHA and can be crucial during an inspection or after an incident.