Have you ever wished you could handle framing, sheathing, and insulation all in one step? That’s the core idea behind Structural Insulated Panels, or SIPs.

Imagine a huge, strong sandwich. A thick core of rigid foam insulation is bonded between two structural boards, usually oriented strand board (OSB). This process creates a single, powerful building component that simplifies construction.

What Exactly Are Structural Insulated Panels?

For builders in the Bay Area, SIPs offer a smart way to construct walls, roofs, and floors. They help us meet strict energy codes and manage high labor costs.

Image Caption: A diagram showing the layered construction of a Structural Insulated Panel (SIP), highlighting the OSB facings and the inner foam core.

Unlike traditional stick-framing, SIPs arrive at your Berkeley or Oakland job site as large, pre-made panels. This all-in-one system speeds up construction time dramatically.

The real benefit is the design. SIPs create an airtight building envelope that is incredibly strong and energy-efficient. The solid, continuous insulation eliminates "thermal bridging," where heat escapes through wood studs, making it easier to meet California's Title 24 energy standards.

The Anatomy of a SIP: What’s Inside?

To understand SIPs, let’s look at what they’re made of. Each layer has a specific job, and together, they create a superior building component.

Here's a quick breakdown of a SIP’s key parts.

SIP Components at a Glance

| Component | Material | Primary Function |

|---|---|---|

| Structural Facings | Oriented Strand Board (OSB) | Provides the panel's strength and acts like sheathing. |

| Insulating Core | Expanded Polystyrene (EPS) or Extruded Polystyrene (XPS) | Delivers continuous, high-R-value insulation and stops thermal bridging. |

| Adhesive | High-strength structural adhesive | Bonds the core and facings together to create a unified panel. |

These three parts work together to deliver impressive performance.

- Structural Facings: The outer skins are usually OSB, a durable and moisture-resistant material. These facings carry the structural load. To learn more, read our guide on what is engineered wood.

- Insulating Foam Core: The center of the panel is a solid block of rigid foam. This core provides an unbroken thermal barrier and a high R-value.

- Adhesive: A powerful, industrial-grade glue fuses the foam core to the facings. This bond turns the three layers into a single structural element.

The Core Benefits of Building with SIPs in the Bay Area

For builders in Berkeley, Oakland, and across the Bay Area, choosing the right materials is about performance and efficiency. SIPs offer major advantages that address the biggest challenges of building in Northern California.

Think of SIPs as a smarter way to build. The benefits start the day they arrive on-site and last for the life of the building.

Unmatched Energy Efficiency

California has some of the toughest energy codes in the nation. Hitting Title 24 requirements is always a top priority for Bay Area builders.

SIPs make this easy. The solid foam core eliminates thermal bridging, the heat transfer that occurs through wood studs in a traditional wall. This creates an incredibly airtight and well-insulated building.

A home built with SIPs requires less energy to heat and cool, which is a huge plus for Bay Area homeowners. The superior insulation of SIPs is essential for maximizing HVAC energy savings. According to the Structural Insulated Panel Association (SIPA), homes built with SIPs can reduce energy costs by up to 60%.

Faster Construction Timelines

For any contractor, time is money. SIPs shine here because they are prefabricated and arrive ready to install.

A small, well-trained crew can make a structure weather-tight in days, not weeks. This speed provides key advantages:

- Reduced Labor Costs: With installation up to 55% faster than traditional methods, you save on labor.

- Fewer Weather Delays: Enclosing the structure quickly protects the project from unpredictable Bay Area weather.

- Quicker Project Turnover: Finishing jobs faster lets you move on to the next one sooner.

Superior Structural Strength

We build in earthquake country, so structural integrity is non-negotiable. SIPs provide incredible strength.

The way the OSB skins are bonded to the foam core creates a structure that acts like a steel I-beam. Lab tests show SIPs can handle immense loads, making them a great choice for standing up to seismic forces.

Healthier Indoor Air Quality

Homeowners are more aware of indoor air quality, especially with wildfire smoke and allergens in our region. A SIP structure is so airtight that you gain precise control over the indoor environment.

- Reduced Air Leaks: The tight envelope keeps dust and allergens out.

- Controlled Ventilation: A tight shell allows for a high-efficiency ventilation system that provides fresh, filtered air.

- No Wall Cavities: The solid foam core means no empty spaces for mold or pests to thrive.

How SIPs Outperform Traditional Stick Framing

When choosing a construction method in the Bay Area, you weigh speed, performance, and cost. While stick framing is familiar, SIPs offer clear advantages for a modern job site.

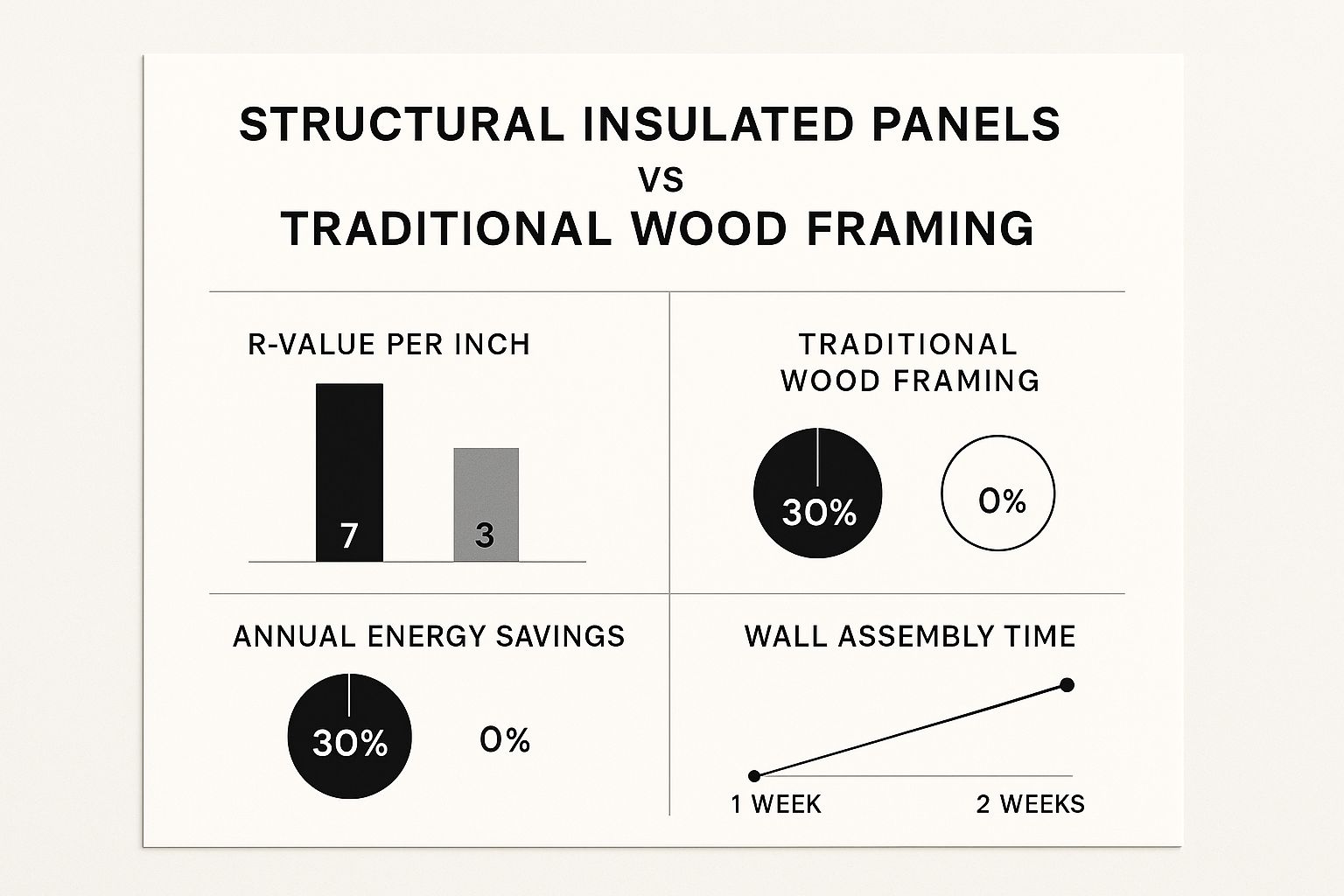

This image shows the key performance differences between SIPs and traditional framing.

Image Caption: A chart comparing the performance metrics of SIPs versus traditional stick framing, focusing on R-value, energy savings, and construction speed.

The numbers show that SIPs deliver much higher insulation value and can cut assembly time in half. This leads to major long-term energy savings.

SIPs vs. Stick Framing: A Head-to-Head Comparison

This table offers a quick look at how each method stacks up.

| Feature | Structural Insulated Panels (SIPs) | Traditional Stick Framing |

|---|---|---|

| Construction Speed | Up to 55% faster. Prefabricated panels cover large areas quickly. | Slower, piece-by-piece assembly on-site. |

| Energy Performance | Superior. Continuous insulation eliminates thermal bridging. | Good, but reduced by thermal bridging through wood studs. |

| Airtightness | Excellent. Fewer joints and factory precision create a tight seal. | Relies on tapes and wraps, with many potential leak points. |

| On-Site Waste | Minimal. Panels are cut to spec in the factory. | High waste from cutting studs, sheathing, and insulation. |

| Labor Needs | Fewer trades. Framing, sheathing, and insulation are one step. | Requires separate crews for framing, sheathing, and insulation. |

Eliminating Thermal Bridging

One of the biggest energy drains in a stick-built home is thermal bridging. Heat finds the easiest path out, which is often through the wood studs.

SIPs solve this problem. The insulation is a solid, continuous core with no studs to interrupt the thermal barrier. This is a huge reason SIP-built homes can cut energy use so dramatically.

Drastically Reduced Construction Time

The prefabricated nature of SIPs makes the building process much faster.

- Faster Framing: A trained crew can erect the walls and roof in days, not weeks.

- Fewer Trades on Site: You handle framing, sheathing, and insulating in one step.

- Less On-Site Waste: Panels arrive manufactured to your project's specs, reducing disposal fees.

Our guide on how to frame a wall shows just how different this process is from traditional methods.

Planning Your First SIP Project

A successful SIP project starts with careful, upfront planning. Every panel is precision-cut in the factory, so decisions must be made early.

This front-loaded approach reduces guesswork and costly changes later on. For Bay Area architects and contractors, it means a more predictable project.

Image Caption: An architectural rendering of a modern home design, demonstrating the clean lines and open spaces achievable with SIP construction.

Key Design Considerations

The design phase is where the real work happens. Every detail must be final before the SIPs are made.

- Mechanical, Electrical, and Plumbing (MEP): You must plan the routes for all ducts, pipes, and wires. Small channels, or chases, are pre-cut into the foam core.

- Window and Door Openings: All rough openings are cut at the factory, so you need final specs early.

- Structural Details: Work with an engineer to confirm all load-bearing points, roof pitches, and connection details.

- Panel Layout: A detailed shop drawing shows exactly where each numbered panel goes.

A Different Workflow for a Better Result

Working with SIPs requires a shift in mindset. You are designing a complete, integrated building system.

This detailed planning also makes the permitting process smoother. Meticulous plans make it easier to show compliance with California’s tough building codes. Our Building Permit Checklist is an excellent resource for local requirements.

The time you invest in planning translates directly to savings in labor and materials on the job site. Using tools for accurate construction cost estimates per square foot can also help with budgeting.

Why SIPs Are a Smart Choice for Sustainable Construction

The construction industry is moving toward smarter, more sustainable methods. SIPs are at the forefront of this movement.

In California, where green building is a requirement, SIPs offer a direct path to high-performance, eco-friendly buildings. They represent a change from wasteful, piece-by-piece framing to efficient, factory-built systems.

Meeting High-Performance Building Standards

Builders and architects in the Bay Area are often asked to meet green building certifications like LEED and Passive House. SIP construction is a perfect match for these standards.

- Superior Airtightness: SIPs create a very tight building envelope, a key requirement for Passive House certification.

- Continuous Insulation: By eliminating thermal bridging, SIPs provide the high-R-value insulation needed for LEED and Passive House.

- Reduced Material Waste: Factory-cut panels mean far less on-site waste, which earns points toward LEED certification.

A Smaller Carbon Footprint

The OSB facings in SIPs are made from fast-growing, renewable wood resources. The manufacturing process itself is highly efficient.

More importantly, the energy performance of a SIP home means it uses far less energy over its lifetime. According to the California Energy Commission, this helps reduce the state's overall energy consumption. You can learn more in our article on what is sustainable building.

Your Bay Area Partner for SIP Construction

Using SIPs is much simpler when you have the right partner. At Truitt & White, we are your go-to resource for high-performance building in the Bay Area.

Image Caption: The Truitt & White lumberyard in Berkeley, showcasing a wide selection of high-quality building materials available to Bay Area contractors.

Our team is here to help you navigate every stage of your SIP build. From sourcing materials to offering technical advice, we have the expertise to make your project a success.

Local Expertise You Can Count On

Whether you are an architect designing your first SIP home or a contractor looking to speed up your schedule, our team can help.

- Source the Right Materials: We connect you with top-tier SIP manufacturers.

- Navigate Local Codes: We understand Bay Area building requirements.

- Provide Technical Support: Our staff can answer your questions on installation and best practices.

Ready to see how SIPs can improve your next project? Visit our Berkeley showroom or contact our team for a consultation to get started.

Frequently Asked Questions About SIPs

1. Are SIPs more expensive than traditional wood framing?

While the initial material cost for SIPs can be higher, the total project cost is often competitive. You save money through reduced labor costs, minimal on-site waste, and the ability to use smaller, less expensive HVAC systems.

2. How do SIPs perform in an earthquake?

SIPs are incredibly strong and perform very well in seismic events. The solid, composite structure is more rigid and resilient than conventional stick framing, providing excellent resistance to the forces common in Bay Area earthquakes.

3. Can you remodel a home built with SIPs?

Yes, but it requires careful planning. Since the panels are structural, you must consult a structural engineer before cutting new openings for windows or doors to ensure the building’s integrity is maintained.

4. How do SIPs handle moisture and pests?

SIPs are very resistant to moisture and pests. The solid foam core offers no food for termites or insects, and the lack of wall cavities prevents moisture from getting trapped, which reduces the risk of mold.

5. What kinds of exterior siding can be used on SIPs?

You can apply almost any exterior finish to SIPs. The continuous OSB surface provides a solid nailing base for siding, stucco, brick veneer, or metal panels, giving you complete design flexibility.

At Truitt & White, we're committed to supplying Bay Area builders with the high-performance materials and expertise needed to build for the future.

Visit our Berkeley showroom for expert advice on your next project.