A proper building materials list template is so much more than a simple checklist. When you treat it like the dynamic tool it is, it becomes the command center for your entire build, preventing budget overruns, simplifying procurement, and keeping your project right on schedule. It transforms a basic list into one of your most powerful project management assets.

Why a Smarter Materials List is Crucial for Bay Area Projects

Let's be real—a poorly managed materials list is a fast track to job site chaos. We’ve all seen it. Countless contractors in the Bay Area have dealt with the frustration of a project grinding to a halt because a critical item was missed, leading to costly delays and unhappy clients.

The key is to reframe how you see your materials list. Stop thinking of it as a static document and start treating it as your project's command center. This shift in mindset is vital in the high-stakes Bay Area market where efficiency and accuracy directly impact your bottom line.

Control Costs and Prevent Waste

One of the biggest money pits on any project is over-ordering and waste. A well-structured template is your best defense. By tracking every board, screw, and fixture with precision, you reduce waste and keep your budget from spiraling.

This level of detail also helps you create transparent, rock-solid quotes. When a client in Berkeley or Oakland sees a professionally organized list, it builds instant trust and confidence in your process.

Streamline Procurement and Scheduling

Your list isn't just about what you need; it's about when you need it. By noting lead times for specialty items—like custom windows from Marvin or specific grades of lumber—you can dodge schedule-killing supply chain gaps. It empowers you to coordinate with suppliers and ensure everything arrives on-site exactly when needed.

Having a smarter list gives you a crystal-clear view of your project's demands, which helps you build stronger partnerships with local suppliers. For a reliable source, exploring a full inventory of building materials in the San Francisco Bay Area can be a game-changer for keeping your jobs well-stocked.

Building Your Template for Maximum Utility

Ready to build a building materials list template that actually works for you? Let's get beyond a simple checklist and create a document that pulls its weight on every job. We're talking about a go-to template in Google Sheets or Microsoft Excel that you can adapt for anything from a Berkeley remodel to a new build in Oakland.

A truly useful template hinges on well-thought-out columns that do more than just list items. Forget generic headers; think about the specific information you need to keep a project on track. This simple shift turns a basic list into a powerful command center for your budget and procurement.

Essential Columns for Clarity

The first step toward a clean, functional list is sorting everything by category. It seems simple, but it’s a game-changer. For instance, if you're tackling a deck project, you'll be dealing with framing lumber, decking, hardware, and finishes.

Grouping these materials helps you see the big picture and makes placing supplier orders much cleaner. For some ideas on how to break down a project, take a look at our deck planning guide and materials list.

Key Fields for Your Building Materials Template

| Column Name | Purpose & Example | Why It Matters |

|---|---|---|

| Item & SKU | Be painfully specific. Not "lumber," but "Redwood 2×6 Decking – SKU: RW2612." | Precision is everything. This eliminates costly ordering mistakes and ensures you get the exact material you specified. |

| Category | Assign each item a clear group: Framing, Electrical, Decking, Exterior Finishes. | This lets you sort your list to see costs per phase, consolidate supplier orders, and track progress more effectively. |

| Quantity Required | The exact count you need for the job—e.g., 150 boards, 5 boxes of screws. | This is the foundation of your budget. An accurate quantity is non-negotiable for cost control. |

| Unit Cost | The price per board, box, or linear foot. | This field, combined with quantity, drives your total cost calculations. It’s essential for real-time budget tracking. |

| Total Cost | A simple formula: Quantity Required * Unit Cost. | This is your at-a-glance budget. The formula updates automatically, so you always know where your numbers stand. |

| Supplier | Note where the material is coming from, like Truitt & White. | When you’re juggling multiple suppliers for a Bay Area project, this column is critical for coordinating orders and deliveries. |

| Status | A dropdown menu with options like To Order, Ordered, Delivered, On Site. | This gives you a live look at your procurement pipeline. You can see what’s been handled and what needs immediate attention. |

With these columns in place, your template becomes more than a list—it's a living document that gives you complete control over your materials from bid to final installation.

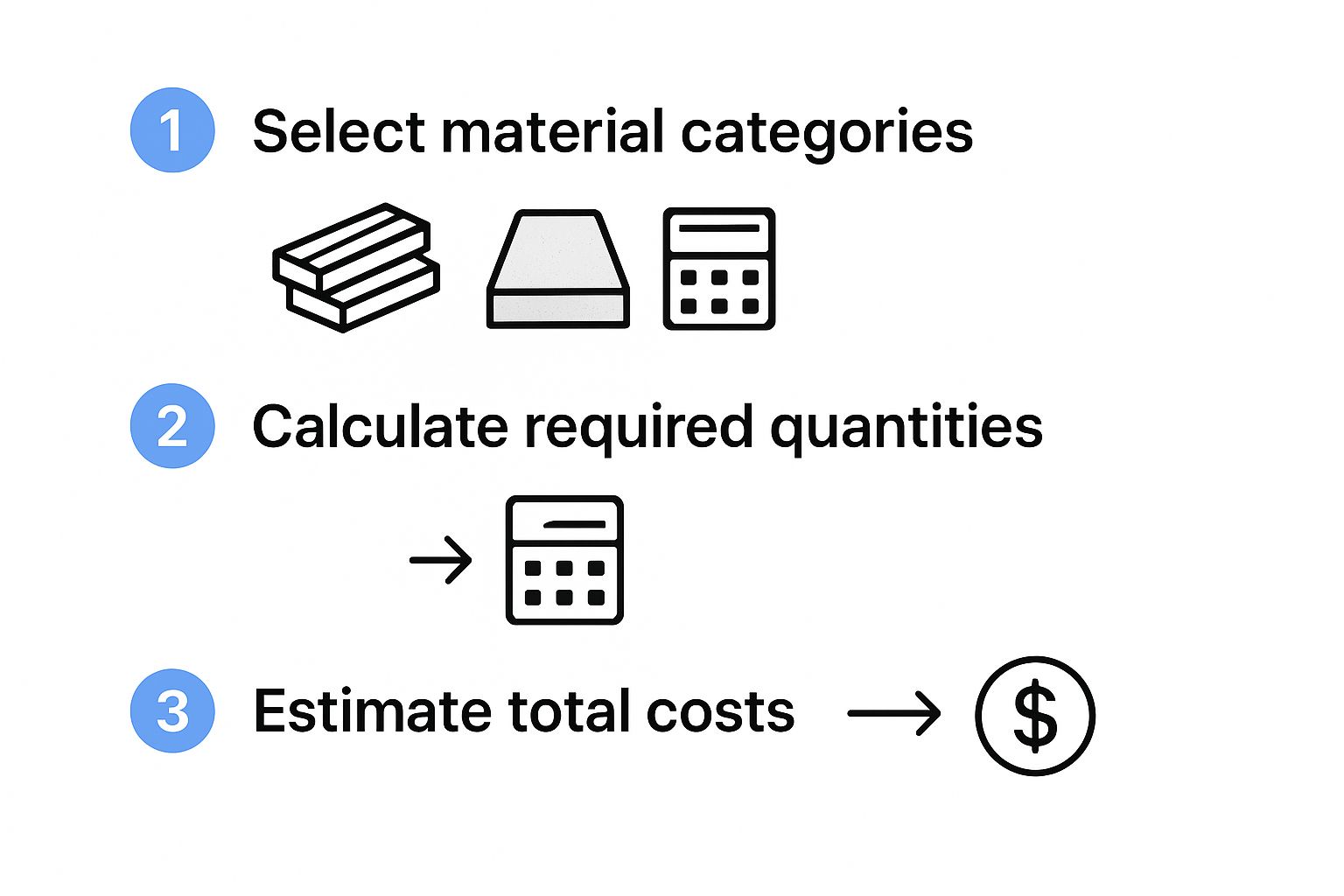

This visual shows how that organized thinking flows directly from broad categories into hard budget numbers.

As you can see, the process is logical: start with big-picture phases, drill down into specific materials, and then calculate your costs. This structured approach is fundamental to keeping your project’s finances in check, especially in the competitive Bay Area construction market.

Turning Your List into a Financial Command Center

Alright, you've got your material list structured. Now it's time for the real magic: turning that checklist into a financial dashboard that gives you total control over your project's budget. This is where a good list separates the pros from the amateurs.

The first move is simple but critical. Add two new columns to your spreadsheet: ‘Estimated Total’ and ‘Actual Cost.’ This small change is the foundation for keeping a close eye on your budget's health from start to finish.

Automating Your Cost Calculations

You don’t need to be a spreadsheet wizard for this part. In your 'Estimated Total' column, a basic formula is all it takes. For example, if your 'Quantity' is in column C and 'Unit Cost' is in column D, use =PRODUCT(C2,D2) to instantly get a cost estimate for that line item.

As you start getting invoices from suppliers in Berkeley or Oakland, plug those final numbers into the 'Actual Cost' column. Having these figures side-by-side gives you an immediate, clear picture of where you are over or under budget. It’s one of the most practical construction cost management strategies you can implement.

Creating a Master Budget Summary

To finish off your command center, carve out a small section at the top of your worksheet. This is where you’ll track the big picture with three essential numbers:

- Total Estimated Budget: Use a

=SUM()formula to add up every number in your 'Estimated Total' column. - Total Spent to Date: Do the same for your 'Actual Cost' column with another

=SUM()formula. - Budget Remaining: This is just a simple subtraction: your 'Total Estimated Budget' minus your 'Total Spent to Date.'

This dynamic summary is your project's pulse. It lets you make smart, informed decisions on the fly and clearly shows the financial benefits of certain decisions, like investing in upgrades covered in our guide on home improvements for energy conservation.

Adapting Your Template for Bay Area Green Building Standards

In the Bay Area, sustainable construction isn't just a trend—it's a core requirement for many clients and municipalities. Proving compliance with standards like CalGreen or earning a LEED certification is a huge part of the job for forward-thinking builders in Berkeley, Oakland, and beyond.

Your building materials list template can be one of your most powerful tools for this. With a few tweaks, it becomes the perfect way to track and document every sustainable material you choose. This level of detail is a serious competitive advantage in the local market.

Adding Green Building Metrics to Your List

To prepare your template for green projects, just add a few custom columns for clear documentation.

- Sustainability Certification: Note credentials like FSC Certified for lumber, GreenGuard Gold for interior finishes, or Cradle to Cradle for various products.

- Recycled Content %: A simple column to track the percentage of post-consumer or post-industrial recycled materials, a key metric for many green building programs.

- VOC Levels (g/L): Document the Volatile Organic Compound levels for all your paints, sealants, and adhesives to prove you're meeting indoor air quality standards.

This growing demand for materials like reclaimed wood, low-VOC paints, and high-performance insulation is a global shift. According to Grand View Research, the green building materials market is projected to grow significantly, reflecting where consumer and regulatory focus is headed.

At Truitt & White, we can help you source the right products for any project, big or small. Learn more about our commitment to green building materials and see how we support sustainable construction across the Bay Area.

Pro Tips for an Advanced Building Materials List

Once you've got a functional building materials list template, it's time to add a few pro-level tweaks. These are the small changes that seasoned Bay Area project managers use to turn a simple list into a powerful project dashboard.

You can start by using conditional formatting in your spreadsheet program. This feature automatically color-codes cells based on their content, giving you critical information at a glance. For instance, set a rule so a row turns green when you mark the status "Delivered" or red if it’s "Delayed," so you know exactly where to focus.

Streamlining Data and Organization

Another great way to tighten things up is by using drop-down menus for specific columns. This works perfectly for fields like 'Supplier,' 'Status,' or 'Category' (e.g., Framing, Finishes). It drastically cuts down on typos and keeps the terminology consistent, especially when multiple people are updating the list.

Here's another trick: organize your workbook with separate tabs. Instead of wrestling with one gigantic list, create dedicated tabs for different project phases—like 'Foundation,' 'Framing,' or 'Electrical'—or even for individual purchase orders. This keeps your main list manageable on a complex Berkeley remodel or a new build in Oakland.

These aren't just fussy habits; they’re about creating a responsive system that actively helps you manage a project. This idea of using clear systems is something we see in broader industry goals from partners like Build It Green, who promote healthier, more efficient building practices.

Your Building Materials List Questions Answered

Over the years, we've heard just about every question from builders, contractors, and remodelers about how to wrestle their materials lists into submission. Here are some of the most common ones we tackle, along with some practical advice to help you fine-tune your own process.

How Do I Account for Material Waste in My Template?

This is a classic—and crucial—question. The best practice is to add a dedicated ‘Waste Factor’ percentage column right into your building materials list template. For materials like framing lumber or drywall, a 10-15% waste factor is a standard starting point in the industry.

For something like intricate tile where complex cuts are inevitable, you might need to bump that up. Your 'Total Quantity Needed' column should then automatically calculate this buffer, ensuring you have enough on hand for mistakes and off-cuts.

What Is the Best Software for a Materials List?

Honestly, for the vast majority of residential projects—from a small kitchen remodel in San Francisco to a new build out in Oakland—you don't need to overcomplicate things. Google Sheets or Microsoft Excel are perfect. They give you all the flexibility and collaborative features you need without a steep learning curve.

If you're running massive commercial jobs with multiple teams, you might look into dedicated construction management software like Procore. But for most local contractors, a well-built spreadsheet is more than capable.

How Often Should I Update the Materials List?

Think of your materials list as a living document, not a set-it-and-forget-it tool. It must be updated in real-time as quotes come in, orders are placed, and materials arrive on the job site.

A quick daily check-in, or at the very least a weekly review, is essential. An outdated list is one of the fastest ways to lose control of your costs and project timeline.

Can I Use This Template to Track Lead Times?

Absolutely, and you definitely should. It’s a simple but powerful addition. Just add a ‘Lead Time (Days)’ column and an ‘Expected Delivery Date’ column to your template.

This small change transforms your list into a scheduling powerhouse. It helps you plan procurement so that crucial materials—like custom Bay Area windows and doors—arrive exactly when you need them.

How Can I Manage Multiple Suppliers on One List?

This is where a good spreadsheet really shines. Create a dedicated 'Supplier' column, then use the built-in 'Filter' or 'Sort' functions.

With one click, you can instantly see all the materials you're getting from a specific vendor, like Truitt & White. This makes it incredibly easy to consolidate purchase orders, check on an order's status, and manage all your supplier relationships without juggling multiple documents.

Ready to start sourcing materials for your next project? The team at Truitt & White has the deep inventory and decades of expertise to support builders, architects, and homeowners across the Bay Area. Visit our Berkeley showroom for expert advice and let's get your project started on the right foot.