In the competitive and complex Bay Area construction market, success hinges on more than just quality materials and skilled labor. From navigating Berkeley's stringent building codes to managing tight timelines on a San Francisco remodel, effective project management is the critical framework holding everything together. Mismanaged projects often lead to budget overruns and schedule delays—issues that Bay Area contractors, architects, and builders cannot afford. In fact, a study by KPMG found that only 31% of construction projects come within 10% of their budget.

This guide provides eight essential construction project management tips tailored for the unique challenges of building in our region. These actionable strategies will help you streamline workflows, enhance communication, and deliver projects that exceed client expectations, on time and within budget. To truly build success in the Bay Area, it's crucial to understand the unique demands and landscape of the broader construction industry. Whether you're overseeing a multi-unit development in Oakland or a custom home build, these insights will fortify your process from the ground up.

1. Implement Robust Project Planning and Scheduling

A construction project without a detailed plan is like building a house without a blueprint. Robust project planning and scheduling form the non-negotiable foundation for success, transforming a complex vision into a manageable, step-by-step process. This involves a comprehensive strategy that guides every decision from pre-construction to final handover.

Effective planning, a cornerstone of construction project management tips, involves several critical layers. It starts with a detailed Work Breakdown Structure (WBS) that deconstructs the project into smaller tasks. From there, you establish realistic timelines, identify critical path activities, and develop contingency plans to address challenges.

Why It's a Foundational Tip

A well-structured plan is a dynamic roadmap for your entire team. It ensures every trade, from framers to electricians, is perfectly synchronized, minimizing costly downtime. In the Bay Area, this proactive approach is essential for navigating local challenges, such as seismic retrofitting requirements or complex permitting processes in cities like Berkeley and San Francisco. For a deeper look into these local nuances, you can learn more about the San Francisco Bay Area construction process to better inform your planning.

Actionable Tips for Implementation

- Involve All Stakeholders: Bring subcontractors, suppliers, and key team members into the planning process early. Their insights are invaluable for creating a realistic schedule.

- Use Professional Software: Leverage industry-standard software like Primavera P6 or Microsoft Project to create, manage, and update your schedule.

- Build in Buffer Time: A common rule of thumb is to add a 10-15% time buffer to your schedule. This contingency accounts for unforeseen delays like weather, material shortages, or inspection issues.

- Communicate and Update Constantly: A schedule is a living document. Hold weekly meetings to review progress, update the schedule, and immediately communicate changes to all parties.

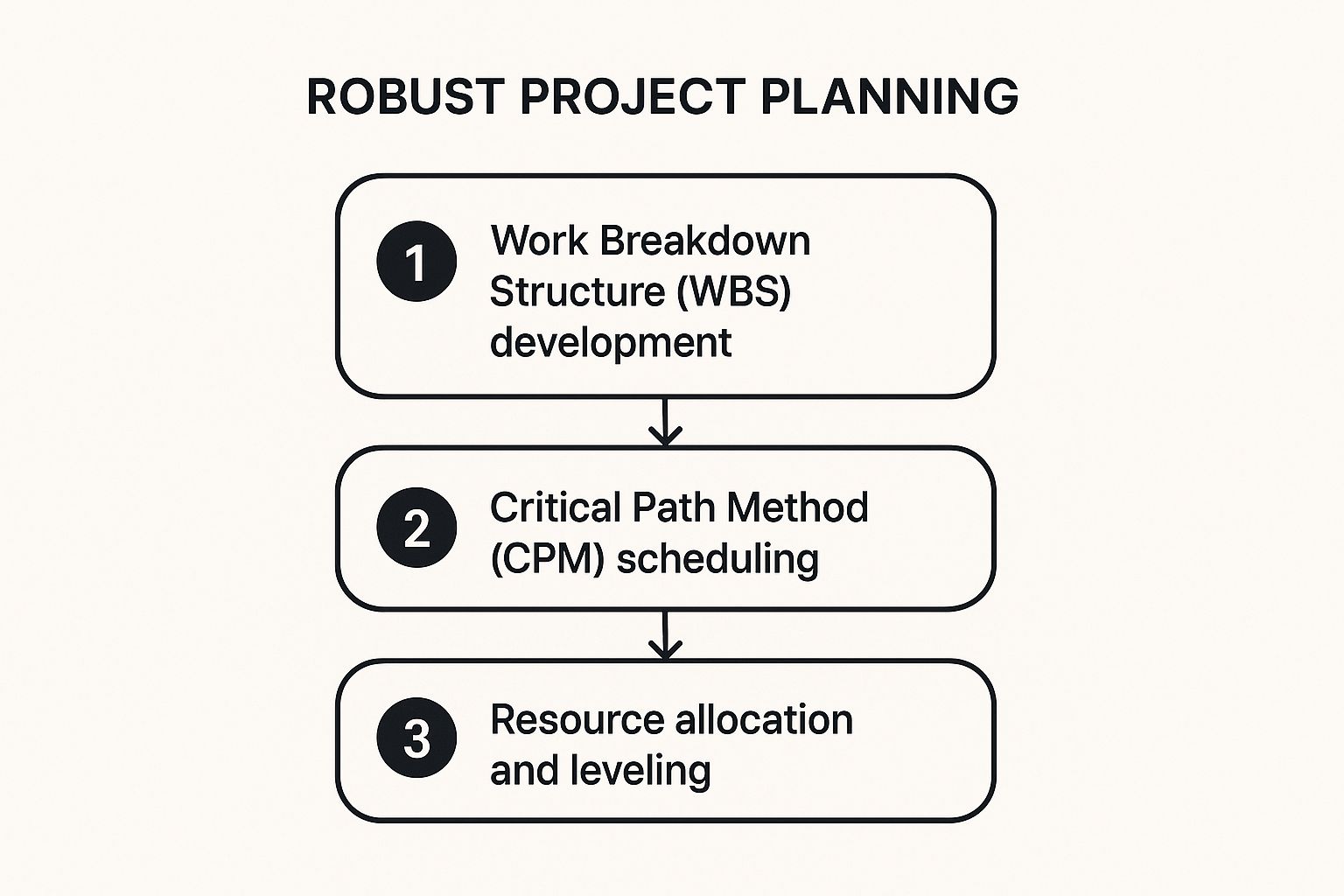

This simple workflow visualizes the core sequence for developing a structured project plan, moving from a high-level breakdown to detailed scheduling and resource management.

Following this logical progression ensures that no task is overlooked and that resources are assigned efficiently based on the most critical activities.

2. Establish Clear Communication Protocols

In construction, a breakdown in communication can be as catastrophic as a structural failure. With dozens of trades, suppliers, and stakeholders involved, clear communication protocols are the nervous system of a successful project. This involves creating a formal system for how, when, and what information is shared.

This strategic approach to information exchange, a vital construction project management tip, prevents misunderstandings, reduces errors, and keeps the project on schedule. It ensures that information flows accurately and efficiently from the office to the job site and back again.

Why It's a Foundational Tip

A defined communication plan eliminates confusion and creates a single source of truth. It ensures that a change order approved in the morning reaches the relevant subcontractor before they begin incorrect work. This is particularly crucial when coordinating complex installations or managing client expectations. By ensuring every decision is documented and accessible, you build a culture of accountability that is central to delivering exceptional results. To learn more about how this aligns with client relationships, you can explore the principles of customer service excellence for professional builders.

Actionable Tips for Implementation

- Use a Centralized Platform: Adopt a cloud-based construction management tool like Procore or PlanGrid. This gives everyone real-time access to the latest plans and RFIs.

- Hold Daily Stand-Up Meetings: For active project phases, conduct brief, 15-minute daily meetings on-site to discuss progress, tasks, and roadblocks.

- Establish Single Points of Contact: Designate one primary contact person for each trade partner, supplier, and the client to avoid mixed messages.

- Document Everything in Writing: Follow up every important phone call or conversation with an email or formal entry in your project management software.

3. Prioritize Safety Management and Compliance

In construction, safety is the bedrock of a successful and ethical project. Prioritizing safety management and compliance means creating a culture where every worker is protected and risks are proactively managed. This involves more than just hard hats; it's a comprehensive system of planning, training, and continuous oversight.

Effective safety management, a critical component of construction project management tips, moves beyond reactive measures. It involves developing site-specific safety plans and fostering an environment where every individual feels empowered to report hazards.

Why It's a Foundational Tip

A robust safety program directly impacts your project's bottom line by preventing costly accidents, reducing insurance premiums, and avoiding steep OSHA fines. It also enhances worker morale, as a safe team is a focused and efficient team. In the Bay Area, safety practices often intersect with green building standards, requiring careful material handling and waste management. You can learn more about green building best practices to integrate safety and sustainability on your next project.

Actionable Tips for Implementation

- Conduct Daily Safety Briefings: Start each day with a "toolbox talk" to discuss the day’s tasks, identify potential hazards, and reinforce safety protocols.

- Implement a Near-Miss Reporting System: Encourage workers to report near-misses without penalty. Analyzing these incidents provides invaluable data to prevent future accidents.

- Leverage Safety Management Software: Use digital tools to track incidents, manage safety training records, conduct inspections, and generate compliance reports.

- Establish a Safety Incentive Program: Reward teams or individuals who consistently demonstrate outstanding safety practices to reinforce a proactive safety culture.

4. Implement Effective Budget and Cost Control

A project’s financial health is just as critical as its structural integrity. Effective budget and cost control are the financial guardrails that prevent a project from spiraling into unprofitability. This involves establishing a detailed budget, continuously monitoring expenditures, and forecasting final costs.

This core component of construction project management tips is about more than just tracking receipts; it's a proactive strategy. It begins with creating a cost baseline and then diligently tracking every dollar spent. By implementing robust controls, project managers can identify budget variances early and make informed decisions.

Why It's a Foundational Tip

Vigilant cost control is what separates profitable projects from financial disasters. It ensures there is enough capital to complete the work and pay subcontractors on time. In a high-cost environment like the Bay Area, where material and labor prices are at a premium, this financial discipline is non-negotiable. Continuous financial health also requires robust cash flow management. Explore additional strategies to manage cash flow effectively to ensure your project maintains liquidity.

Actionable Tips for Implementation

- Use Job Costing Software: Implement construction-specific accounting software like Foundation Software or Viewpoint Vista to integrate accounting with project management.

- Conduct Weekly Cost Reviews: Hold mandatory weekly meetings with your project team to review actual costs against the budget to catch overruns early.

- Establish Clear Approval Thresholds: Define who can authorize expenditures and set clear limits to prevent unauthorized costs.

- Create a Contingency Plan: Allocate a contingency budget, typically 5-10% of the total project cost, specifically for unforeseen risks like design errors or material price fluctuations.

5. Leverage Construction Technology and Digital Tools

In today’s fast-paced construction environment, relying on analog methods is a direct path to inefficiency. Leveraging construction technology and digital tools is a core component of modern project management. This involves adopting integrated platforms to enhance accuracy, streamline collaboration, and provide real-time visibility.

From Building Information Modeling (BIM) and cloud-based software to drones and IoT sensors, these technologies create a connected digital ecosystem. These tools automate manual processes, improve data-driven decision-making, and are essential construction project management tips for staying competitive.

Why It's a Foundational Tip

Digital tools provide a single source of truth, eliminating the information silos that cause delays and rework. By centralizing project data, every stakeholder works from the most current set of plans. This is especially valuable for managing complex financial records; for efficient expense tracking, exploring the best invoice OCR software solutions can significantly reduce manual effort.

Actionable Tips for Implementation

- Start with Pilot Projects: Introduce new technology on a smaller, controlled project first. This allows your team to learn the system before a full-scale rollout.

- Invest in Comprehensive Training: Technology is only as good as the people using it. Provide thorough, ongoing training to ensure your entire team can use new tools. For a closer look at what equipment can make a difference, you can learn more about top-tier project equipment.

- Prioritize Interoperability: Select software platforms that can integrate with each other. A seamless flow of data between your scheduling, budgeting, and modeling tools is critical.

- Establish Strong Data Security Protocols: With increased digital adoption comes the need for robust cybersecurity. Implement strict protocols for data backup, access control, and protection.

- Regularly Evaluate ROI: Continuously assess the return on investment for your technology stack. Measure metrics like time saved and reduction in errors to justify the investment.

6. Develop Strong Quality Assurance and Control Processes

In construction, quality is the result of deliberate, systematic effort. Developing strong Quality Assurance (QA) and Quality Control (QC) processes ensures every component meets or exceeds specifications. QA is the proactive strategy of planning for quality, while QC involves reactive inspections and tests.

This two-pronged approach is a fundamental construction project management tip that prevents costly rework and protects your professional reputation. By embedding quality checks into every phase, you transform project standards from a vague goal into a measurable outcome.

Why It's a Foundational Tip

A robust quality management system catches defects before they can cause major problems. It ensures the finished product is compliant with building codes and aligns with client expectations. In areas with specific demands like the seismic requirements in the Bay Area, a documented quality process is non-negotiable for proving compliance and ensuring long-term structural integrity.

Actionable Tips for Implementation

- Create Project-Specific Quality Plans: Develop a detailed quality plan tailored to the project’s unique materials, methods, and performance requirements.

- Leverage Digital Inspection Tools: Use software and mobile apps for quality control inspections to allow for real-time photo documentation and instant report generation.

- Establish Key Quality Metrics (KPIs): Define and track specific Key Performance Indicators (KPIs) to measure quality, such as the number of failed inspections or the cost of rework.

- Implement Quality Training Programs: Ensure all team members and subcontractors understand the project’s quality standards through kickoff meetings and regular training.

7. Master Risk Management and Contingency Planning

In construction, uncertainty is the only certainty. Mastering risk management and contingency planning is how successful project managers turn potential disasters into manageable challenges. It’s a proactive process of identifying, assessing, and mitigating threats that could derail your project.

This essential discipline, a key among modern construction project management tips, involves creating a formal system to handle everything from weather delays to supply chain disruptions. Effective risk management isn't about eliminating all risk; it's about understanding it so well that you have a plan ready before it materializes.

Why It's a Foundational Tip

A robust risk management strategy protects your project's profitability and your company's reputation. By anticipating potential setbacks, you can allocate resources for contingency plans. In the Bay Area, this is especially important for mitigating risks related to seismic activity, local regulations, and potential supply chain issues for specialized building materials.

Actionable Tips for Implementation

- Conduct Risk Workshops: Bring together all stakeholders to brainstorm potential risks at each project phase. Diverse perspectives will uncover risks you might otherwise miss.

- Create a Risk Register: Document every identified risk in a formal register. Assign a probability score, an impact score, and a designated "risk owner."

- Use Historical Data: Analyze past projects to inform your risk assessments. If a particular supplier consistently caused delays, that data should increase the probability score for supply chain risks.

- Establish Clear Response Protocols: Develop specific, pre-approved action plans for high-probability, high-impact risks to ensure a swift response.

- Update and Review Regularly: Your risk register is a living document. Review it during weekly project meetings to update statuses and identify new threats.

8. Optimize Supply Chain and Resource Management

A construction project's momentum depends entirely on the timely arrival of materials and resources. Optimizing your supply chain is one of the most critical construction project management tips for preventing costly delays. It involves a strategic approach to procurement, logistics, and vendor management.

Effective supply chain management moves beyond simply placing orders; it's about building a resilient and efficient flow of goods. This requires coordinating delivery schedules with on-site activities and managing inventory to avoid shortages.

Why It's a Foundational Tip

A disorganized supply chain is a primary source of project friction, leading to idle crews and schedule slippage. In a competitive market like the Bay Area, where lead times for specialized materials can be long, a well-managed supply chain is a non-negotiable asset. Proactive resource planning allows you to secure high-quality materials, like specific lumber grades needed for framing. You can learn more about choosing the best lumber for your build to inform your procurement strategy.

Actionable Tips for Implementation

- Develop Strategic Supplier Partnerships: Build long-term relationships with trusted suppliers who understand your needs, offer reliable service, and provide expert advice.

- Use Supply Chain Management Software: Leverage technology to track orders, monitor inventory levels, and manage delivery schedules in real-time.

- Implement Vendor Performance Metrics: Establish clear criteria for evaluating suppliers on reliability, quality, and communication.

- Coordinate Deliveries with Site Activities: Work closely with your site superintendent to schedule deliveries to align with the construction timeline, minimizing on-site storage needs.

Frequently Asked Questions (FAQs)

1. What is the most critical construction project management tip for a Bay Area contractor?

Robust project planning is the most critical tip. The Bay Area's complex regulatory landscape, seismic requirements, and high costs demand a meticulously detailed plan to manage timelines, budgets, and compliance from day one.

2. How can I improve communication with my subcontractors and suppliers?

Use a centralized digital platform like Procore or PlanGrid to share updated documents in real-time. Also, hold brief, daily stand-up meetings on-site to align on immediate tasks and resolve issues quickly.

3. What's a simple way to start implementing better cost control?

Begin by holding weekly cost review meetings. This simple habit forces you and your team to regularly compare actual spending against the budget, catching overruns early when they are easier to manage.

4. How do I manage the risk of material delays in the Bay Area?

Build strong partnerships with reliable local suppliers like Truitt & White who have deep inventory and understand regional logistics. Also, order critical materials with long lead times well in advance and build buffer time into your schedule.

5. Which technology gives the best return on investment for a small to mid-sized builder?

Cloud-based project management software often provides the best ROI. It streamlines communication, document management, and scheduling for a relatively low monthly cost, significantly reducing administrative time and errors.

Partner with Experts for Seamless Project Execution

Mastering the art and science of construction project management is an ongoing journey. The tips detailed in this guide—from robust planning to mastering risk management—are the foundational pillars of success in the competitive Bay Area market. These are actionable frameworks that separate profitable contractors from those who constantly battle delays and budget overruns.

Applying these construction project management tips will empower you to navigate the complexities of any build, from a custom home in the Berkeley hills to a commercial remodel in downtown Oakland. The true value emerges when these practices become ingrained in your daily operations. By prioritizing these concepts, you build more than just structures; you build a reputation for reliability, excellence, and unwavering quality.

Actionable Next Steps to Elevate Your Projects

To truly integrate these principles, focus on implementing one or two key improvements on your next project.

- Review Your Communication Workflow: Could a daily huddle or a dedicated project management app eliminate common misunderstandings? Start there.

- Assess Your Supply Chain: Are your material suppliers true partners who understand your timelines and the unique demands of Bay Area building codes? A reliable supply chain, like the one offered by a lumberyard near Oakland, is an effective risk mitigation tool.

- Embrace One New Technology: You don't need to digitize everything at once. Introduce a single tool, like scheduling software or a drone for site mapping, and measure its impact.

The consistent application of these tips creates a powerful ripple effect. It leads to safer job sites, more accurate budgets, and higher-quality outcomes that homeowners, architects, and developers notice. Building with confidence starts with a solid plan and ends with the right partners by your side.

A crucial element of effective supply chain management is partnering with a supplier who acts as an extension of your team. For nearly 80 years, Truitt & White has provided Bay Area professionals with premium Berkeley building materials, expert advice, and logistical support designed to keep your projects on schedule and on budget. Visit our Berkeley showroom for expert advice or explore our site to learn how our deep industry knowledge can become your competitive advantage. Connect with us today.