You can think of R-value a lot like the SPF rating on sunscreen—the higher the number, the better the protection. In construction, R-value measures how well insulation can resist the flow of heat.

Whether you're tackling a San Francisco remodel or new construction in Berkeley, a higher R-value means the insulation is working harder to keep your building comfortable. It's the key to lower energy bills and a stable indoor environment, no matter the season.

Why R-Value Is Critical for Bay Area Construction Projects

Alt text: Rolls of pink fiberglass insulation ready for installation in a new construction project.

For builders and remodelers in the Bay Area, understanding R-value is essential. It's the standard we use to measure an insulation material's ability to create a thermal barrier.

This barrier is what keeps a home cozy during a damp Oakland winter and cool during a summer heatwave. A higher R-value simply means greater thermal resistance, making the material better at stopping heat transfer.

The Core Benefits of High R-Value Insulation

Choosing the right insulation does more than just control temperature. It brings several benefits that are crucial for any modern building project in Berkeley, Oakland, and beyond.

- Enhanced Energy Efficiency: A well-insulated building gives the HVAC system a break. According to ENERGY STAR, homeowners can cut heating and cooling costs by an average of 15% by air sealing and adding proper insulation.

- Improved Indoor Comfort: Good insulation eliminates drafts and hot spots. This creates a consistently pleasant environment for the people living or working inside.

- Compliance with California's Title 24: California's Title 24 energy code requires specific minimum R-values for different parts of a building. Following these rules ensures all new construction and major renovations are built for long-term efficiency.

A Standardized Measurement for Performance

R-value is a scientifically grounded measurement, not just a marketing term. ASTM International formalized the testing standards, giving us the reliable system we use today to compare different materials.

This standardization allows architects and builders to design systems that perform as expected. Remember that insulation is more than just what's in the walls and attic; things like garage doors also make a big difference, as explained in the benefits of insulated garage doors. You can find similar strategies in our guide to weatherproofing windows and doors.

How Insulation R-Value Is Calculated

The number on insulation packaging is a starting point, but knowing how R-value is calculated for a real-world wall or ceiling assembly is key. The R-value is a direct measure of an insulation material's thickness and its ability to resist heat flow.

At its core, R-value measures thermal resistance. A higher number means a material is better at stopping heat. If you stack two R-15 batts, you get a total of R-30.

More Than Just Insulation: R-Values in a Wall Assembly

A common mistake is thinking the insulation's R-value is the R-value of the entire wall. In reality, a wall is a layered system, and every layer contributes to the total R-value.

From the inside out, a typical wall assembly in a Berkeley or Oakland home has multiple materials working together.

- Interior Gypsum Board (Drywall): Offers a small amount of thermal resistance.

- Insulation Layer: Provides the bulk of the thermal performance.

- Exterior Sheathing (like OSB or Plywood): Adds structural integrity and another layer of resistance.

- Air Films: Even thin layers of still air on the interior and exterior surfaces contribute to the total R-value.

To get the total R-value of an assembly, you add up the R-value of each component. This approach is essential for architects designing energy-efficient buildings and for green building certifications, a topic we cover in our guide to LEED certification for Bay Area builders.

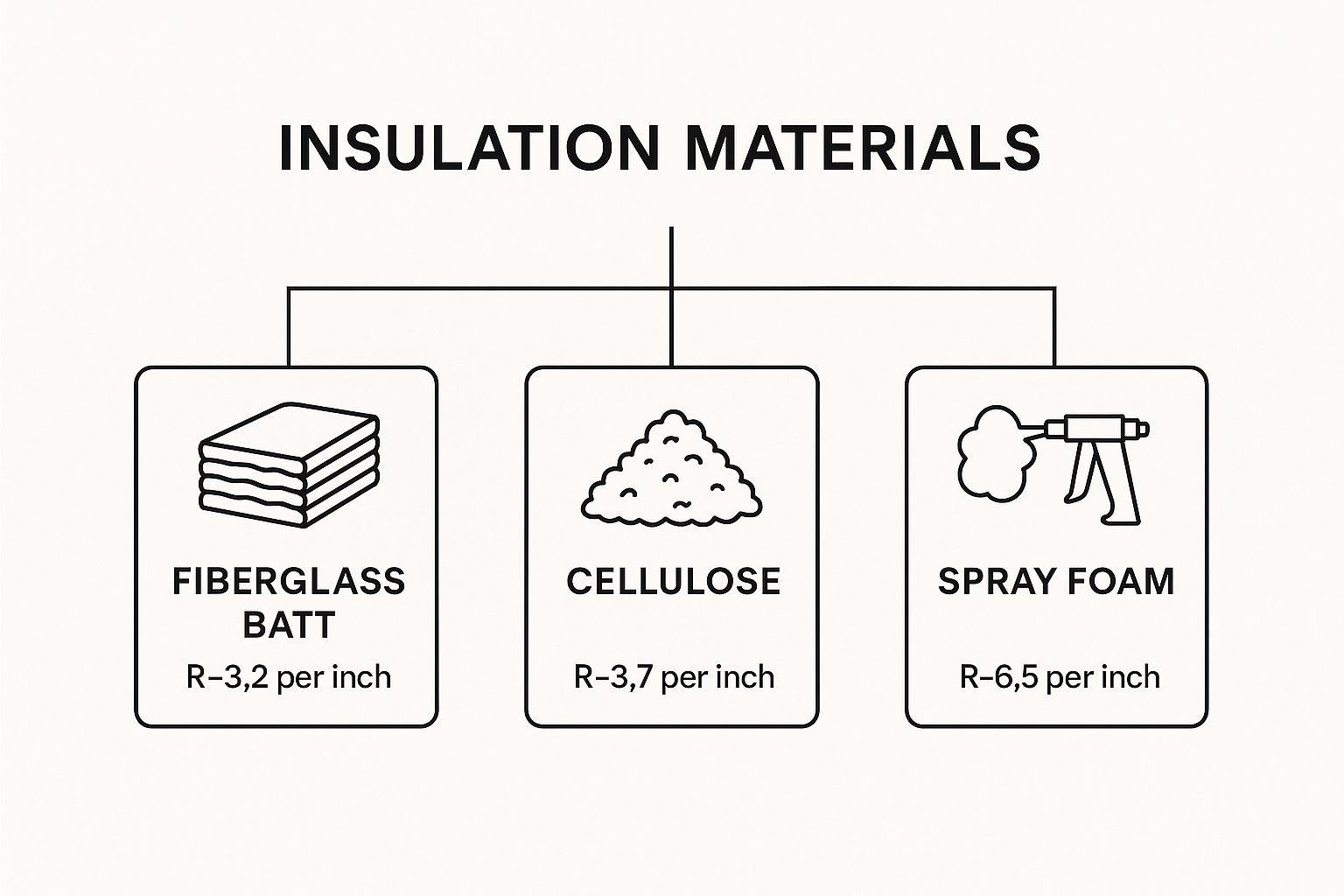

The infographic below shows the R-value per inch for common insulation materials you might find at a Berkeley building materials supplier like Truitt & White.

Alt text: Infographic comparing the R-value per inch for different insulation types like fiberglass, spray foam, and rigid foam.

As you can see, different materials provide varying levels of thermal resistance per inch. Spray foam, for instance, offers nearly double the performance of fiberglass in the same amount of space.

Comparing Common Insulation Materials

Here’s a quick-reference table comparing common insulation types and their best uses in Bay Area construction projects.

| Insulation Material | Typical R-Value (per inch) | Best Bay Area Use Case | Pros and Cons |

|---|---|---|---|

| Fiberglass Batts | R-3.1 to R-4.3 | Standard wood-framed walls and attics. A go-to for cost-effective projects. | Pro: Widely available and affordable. Con: Can lose R-value if compressed or wet. |

| Spray Foam (Closed-Cell) | R-6.0 to R-7.0 | Sealing air leaks in older homes, rim joists, and where space is tight. | Pro: Excellent air barrier and high R-value. Con: Higher upfront cost. |

| Rigid Foam Board (XPS/Polyiso) | R-4.0 to R-6.5 | Exterior continuous insulation, basement walls, and below-grade applications. | Pro: Moisture resistant and structurally stable. Con: Seams must be carefully sealed. |

| Cellulose (Blown-in) | R-3.2 to R-3.8 | Retrofitting existing wall cavities and dense-packing attics. | Pro: Made from recycled materials. Con: Can settle over time if not installed correctly. |

This table shows that the "best" material depends on the specific application and performance goals of your project.

Understanding the Inverse: U-Value for Windows and Doors

While R-value is perfect for walls and roofs, windows and doors are different. For these, we use U-value (or U-factor), which is the inverse of R-value.

U-value measures how easily heat flows through an object. Because it’s the opposite of R-value, a lower U-value is always better, indicating a more effective insulating product.

This is especially critical for Bay Area projects where large windows are used to capture views of San Francisco. A window with a low U-value prevents heat loss on a chilly morning and keeps cool air inside during a summer heatwave.

Navigating Bay Area R-Value and Title 24 Energy Codes

For builders and architects in California, you can't talk about R-value without talking about the state's energy code. Title 24 sets the rules for creating energy-efficient buildings. Understanding these regulations is about delivering the quality your Bay Area clients demand.

Title 24 is updated every three years to improve efficiency. Homes built in the 1970s often had minimal R-13 in walls and R-22 in ceilings. Today's codes are much stricter and can reduce heat loss by over 50% compared to older homes.

Alt text: A chart showing the increasing insulation R-value requirements in California's Title 24 energy code over the decades.

Decoding Bay Area Climate Zones and Requirements

California has 16 climate zones, and the Bay Area includes several. Title 24 requirements change based on the local climate. A project in San Francisco (Climate Zone 3) will have different R-value minimums than one in Livermore (Climate Zone 12).

Here’s a breakdown of the key zones in our area:

- Climate Zone 3 (Coastal): This covers San Francisco, Berkeley, and Oakland, with moderate year-round temperatures.

- Climate Zone 2 (Inland/Cooler): Includes parts of Marin and Sonoma counties, which can have cooler winters.

- Climate Zone 12 (Inland/Warmer): Includes inland areas of Alameda and Contra Costa counties that experience more summer heat.

Knowing your project's climate zone is always the first step.

Title 24 R-Value Minimums for the Building Envelope

Title 24 outlines R-value minimums for every part of a building’s envelope. The exact numbers depend on the climate zone and construction type.

Let's look at typical requirements for different parts of a home in common Bay Area zones.

- Attics and Ceilings: Heat rises, making the attic a key area for energy loss. Title 24 often demands R-38 or R-49 to keep heated air inside during winter.

- Exterior Walls: Wall insulation is your first line of defense. Wood-framed walls typically need R-20 batts in the cavity or a combination of cavity and continuous exterior insulation (e.g., R-13 + R-5).

- Floors Over Unconditioned Spaces: Floors above a crawl space or uninsulated garage need protection. You'll often see requirements for R-19 or R-30 insulation to prevent cold floors.

These standards are part of a larger system. You can explore related strategies in our guide to home improvements for energy conservation.

Proper Installation is a Code Requirement

Title 24 doesn't just specify the R-value; it demands a quality installation. Simply stuffing R-20 batts into a wall cavity won’t pass inspection if the job is sloppy.

Inspectors look for common flaws that reduce performance:

- Compression: When insulation is squashed, its R-value drops. Batts must be cut to fit snugly around pipes and wires.

- Gaps and Voids: Even small gaps become thermal bridges for heat to escape. The entire cavity must be filled.

- Air Sealing: Insulation works best with proper air sealing. Without it, drafts can make even the best insulation less effective.

Our team at Truitt & White can help you select the right materials and ensure your projects exceed Title 24 standards.

Common Issues That Reduce Insulation Performance

The R-value on the package is a best-case scenario. In a real-world Bay Area project, its actual performance can drop if common issues are overlooked.

Understanding what can go wrong helps you make sure the thermal envelope you designed becomes a reality.

The Hidden Energy Thief: Thermal Bridging

One of the biggest performance killers is thermal bridging. This happens when heat travels around the insulation through framing members like wood or steel studs.

Wood has an R-value of about R-1 per inch—much lower than the R-15 or R-21 insulation between the studs. On a chilly San Francisco day, heat will flow out through every stud, bypassing your insulation.

A standard wood-framed wall might have R-21 insulation, but the overall R-value of the wall could drop to R-14 once you factor in thermal bridging.

How to Combat Thermal Bridging

The best way to beat thermal bridging is with a layer of continuous exterior insulation. This usually means adding rigid foam board over the sheathing before the siding goes on.

- It creates an unbroken thermal blanket: This layer covers all framing members, isolating them from outside temperatures.

- It raises the whole-wall R-value: This dramatically boosts the assembly's real-world performance.

- It helps manage moisture: Certain types of rigid foam also act as a weather-resistive barrier.

This strategy is a key part of high-performance building in Berkeley, Oakland, and across the Bay Area.

Common Installation Mistakes That Sabotage R-Value

Beyond thermal bridging, simple installation errors can hurt an insulation's performance. Title 24 inspectors are trained to spot these mistakes.

- Compression: Insulation works by trapping air. When you compress a batt, you crush those air pockets, and its R-value drops.

- Gaps and Voids: Unfilled gaps create a direct path for heat to escape. Every cavity must be completely and uniformly filled.

- Air Leakage: Insulation stops heat conduction but not air movement. Unsealed gaps around windows and pipes allow drafts. Other factors, like unsealed ductwork, can also undermine energy efficiency. Exploring effective ductwork sealing can complement your insulation efforts.

- Moisture Intrusion: Wet insulation is useless. Proper weather barriers and vapor control layers are essential for keeping insulation dry.

Choosing the Right Insulation for Your Bay Area Project

Knowing what R-value is on paper is one thing. Picking the right insulation for a real-world job is where experience matters.

The ideal insulation for a project in foggy San Francisco is different from what you need for a home in the sunny Oakland hills. Each material offers a unique mix of thermal performance and moisture resistance.

Alt text: A contractor installing mineral wool insulation batts between wood studs in a wall assembly.

Profiling Top Insulation Materials

When you visit a professional lumberyard near Oakland like Truitt & White, you'll find a range of high-performance insulation.

Here are the go-to options for Bay Area construction:

- Fiberglass Batts: The cost-effective workhorse of the industry. It’s a solid choice for standard wood-framed walls, attics, and floors, providing R-3.1 to R-4.3 per inch.

- Mineral Wool (Rock Wool): Valued for its fire resistance and sound-dampening abilities. It has a slightly higher R-value than fiberglass and naturally resists moisture.

- Spray Foam Insulation: If you need the highest R-value and an unbeatable air seal, choose closed-cell spray foam. It expands to fill every crack, with an R-value of R-6.0 to R-7.0 per inch.

- Rigid Foam Boards (XPS & Polyiso): These dense boards are for jobs that need structural integrity and moisture resistance. They are the go-to for continuous exterior insulation and foundations.

Bay Area Insulation Project Application Guide

Here’s a quick guide matching common Bay Area building challenges with the right insulation solution.

| Project Area | Primary Challenge | Recommended Insulation | Why It's the Right Choice |

|---|---|---|---|

| A Damp Berkeley Crawl Space | Ground moisture and cool air create a risk of mold and heat loss. | Rigid Foam Board (XPS) | Its closed-cell structure is waterproof, so it won't absorb moisture or lose its R-value. |

| A Vaulted Ceiling Remodel (San Francisco Victorian) | Limited rafter depth makes it hard to meet Title 24 R-value requirements. | Closed-Cell Spray Foam | The high R-value per inch hits code in a shallow space and acts as an air barrier. |

| An Oakland Hills Home (Wildfire Risk) | Building in a Wildland-Urban Interface (WUI) zone demands fire-resistant materials. | Mineral Wool Insulation | Mineral wool is non-combustible and can handle temperatures over 2,000°F. |

| Soundproofing a Shared Wall (Duplex in Albany) | Noise transfer between units is a common complaint. | Mineral Wool Insulation | The dense fiber structure is excellent at absorbing sound waves. |

This problem-solving approach is how professionals select materials.

Beyond the Building Envelope

While insulation is key, other components like windows and doors also play a big role. The materials used in their construction are just as important for efficiency. For a deeper dive, see our guide on the types of wood for doors and windows.

Ultimately, the right choice comes back to a solid understanding of R-value insulation and your project's needs. By working with a knowledgeable supplier, you can be confident you have the right materials.

Frequently Asked Questions About R-Value Insulation

Here are answers to common questions we hear from builders, contractors, and homeowners across the Bay Area.

1. Is a higher R-value always better for Bay Area homes?

Mostly, yes—but you’ll reach a point of diminishing returns. The main goal is to meet or exceed California's Title 24 code requirements for your climate zone. Going far beyond the code, like from R-49 to R-60 in an attic, adds little benefit for the cost.

2. Can I add new insulation over my old attic insulation?

Yes, laying new insulation over the old is a cost-effective way to boost your total R-value. Before you add anything, make sure the old insulation is dry and free of mold or pests. Never place a new vapor barrier on top of the old layer, as this can trap moisture.

3. What is the difference between R-value and U-value?

R-value and U-value measure thermal performance in opposite ways. R-value measures thermal resistance (how well a material blocks heat), so a higher number is better. U-value measures thermal transmittance (how easily heat passes through), so a lower number is better. U-value is used for windows and doors, which you can learn more about by choosing energy-efficient windows.

4. Does a wall's R-value include the wood studs?

No, the R-value on insulation packaging is only for the insulation itself. The real-world "whole-wall" R-value is always lower because wood studs let heat pass through easily, an effect called thermal bridging. A 2×6 wood stud only has an R-value of about R-5.5, which is why continuous exterior insulation is becoming more common.

5. Why do attics require a much higher R-value than walls?

Attics and ceilings need more insulation because heat rises. In winter, a large amount of a home's heat is lost through the roof. To combat this, Title 24 calls for a much higher R-value in the attic—often R-38 to R-49—to trap heated air inside.

At Truitt & White, we're more than a supplier; we're your partner in building excellence. Whether you're navigating Title 24 compliance or selecting materials for a custom build, our team is here to help. Visit our Berkeley showroom or connect with us to discuss your next project.