Lumber from big-box stores is often warped because their business model focuses on volume over quality. They typically stock lower-grade wood from fast-growth trees and use rushed kiln-drying processes that leave too much moisture. This, combined with less-than-ideal storage, creates the warped boards that frustrate builders.

The Pro's Dilemma: Why You Can't Find Straight Lumber at a Chain Store

If you’ve ever spent half a day digging through twisted 2x4s at a big-box store, you’re not alone. Builders and serious DIYers in Berkeley and Oakland want to know: why is it so hard to find decent lumber?

Many people assume all lumber is the same, but that’s a common misstep. Mass-market retailers are in the business of moving a high volume of #2 and #3 grade lumber, which is known for its inconsistency.

The time you spend sorting through warped boards isn't just an inconvenience. It's a direct hit to your labor budget and project timeline, turning a simple material run into a costly delay.

The True Cost of "Cheaper" Wood

That low price you see at a chain store is often misleading. The real cost shows up in other, more painful ways:

- Wasted Time: You can burn hours sorting a huge stack just to find a handful of straight, usable boards.

- Material Waste: You have to toss out the unusable pieces you already paid for.

- Project Callbacks: Warped framing can cause drywall cracks and uneven floors, hurting your reputation long after the job is done.

A huge part of the problem is how the lumber is treated before it hits the shelf. Poor handling is common, and understanding proper lumber storage practices highlights these shortfalls. For professionals who know time is money, sourcing from a dedicated builders supply store in Oakland is a smart business strategy.

Big-Box Lumber vs. Professional-Grade Lumber

This table breaks down what you can expect from a mass retailer versus a professional lumberyard like Truitt & White.

| Characteristic | Big-Box Store Lumber | Truitt & White Professional Grade Lumber |

|---|---|---|

| Wood Grade | Typically #2 or #3 grade; more knots and defects. | Select Structural and #1 grade available; consistent quality. |

| Moisture Content | Often higher due to rushed kiln-drying. | Carefully kiln-dried to an optimal 19% or less moisture content. |

| Sourcing | Sourced from fast-growth trees, leading to less density. | Sourced from slower-growth, denser wood for better stability. |

| Storage | Stored in open-air conditions or high-traffic retail floors. | Stored in controlled environments to protect from Bay Area weather. |

| Selection Process | Self-service; you spend your time sorting through stacks. | Expert yard staff helps select and pull quality materials for you. |

| Intended Customer | Geared toward the average DIYer and price-conscious shopper. | Geared toward professional contractors who demand quality. |

While the price tag might be lower at a big-box store, the trade-off in quality, time, and final results is something every pro needs to weigh carefully.

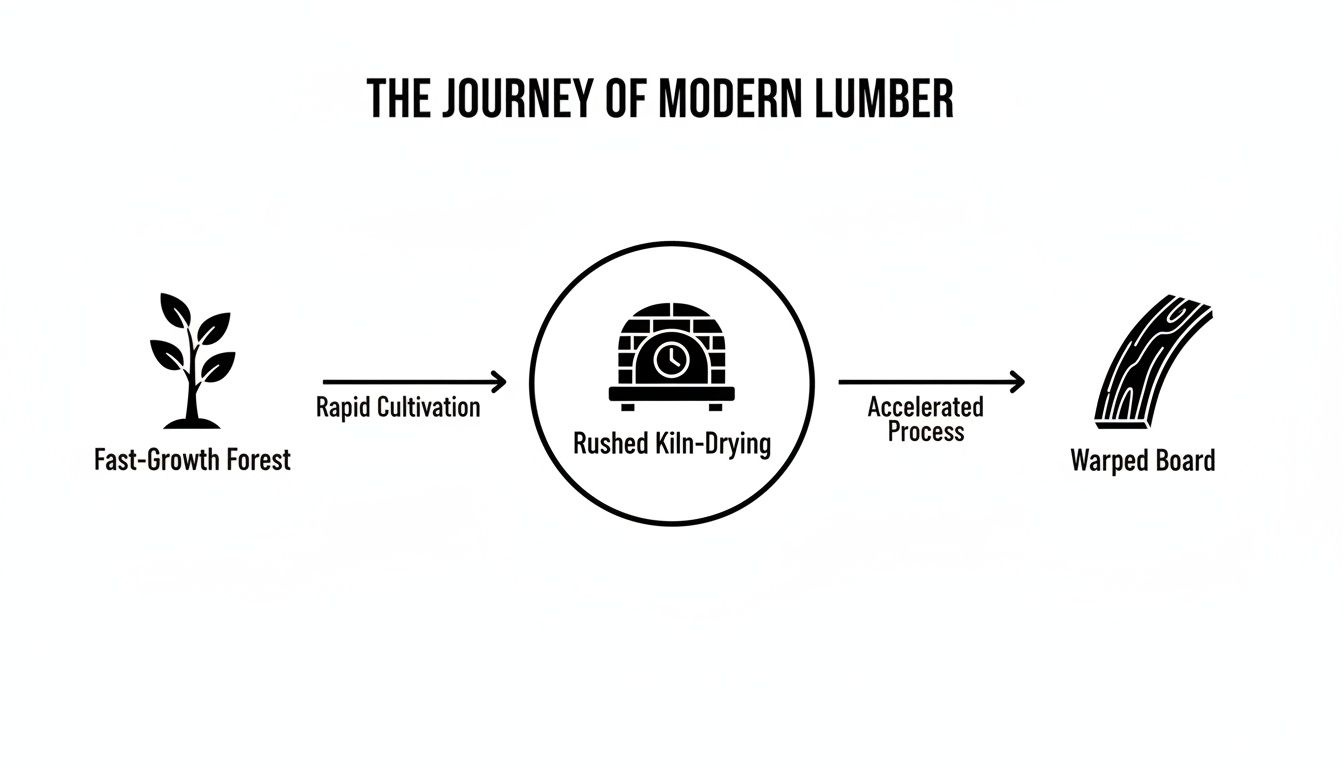

The Journey of Modern Lumber: From Fast-Growth Forest to Warped Board

To understand why that 2×4 looks more like a hockey stick, you have to know its origin story. Today’s lumber comes from massive tree farms where speed is the top priority.

In the past, lumber was harvested from old-growth forests where trees grew slowly. This created dense, tight growth rings, which meant the wood was naturally stable and strong.

Rushed from Forest to Kiln

Modern forests are engineered for rapid harvesting. Trees like pine and fir are often cut down in as little as 20 to 30 years. This "juvenile wood" has wider, less stable growth rings and is more prone to warping.

After harvesting, the lumber goes to a kiln to be dried. Green lumber is full of water, which must be removed in a controlled way. But just like in the forest, speed often wins out over quality.

Big-box suppliers often rush the kiln-drying process to get lumber to stores faster. When wood is dried too quickly or unevenly, it creates internal stress that causes it to warp, cup, or bow on your job site.

The Problem with High Moisture Content

Proper kiln-drying brings the wood's moisture content down to a stable level, typically below 19%. However, lumber destined for mass-market retailers often leaves the mill sitting at this maximum allowed limit.

This creates a headache for builders in Berkeley, Oakland, and the Bay Area. When this damp wood arrives at a job site, it releases its excess moisture into the drier air. This process causes the wood to change shape, leading directly to twisted and bowed boards.

How a Board Is Cut Determines Its Stability

Why do some boards stay straight while others twist? The answer often lies in how they were cut from the log.

Go into any big-box store, and you'll find that nearly every board is flat-sawn. This method is the fastest and cheapest way to get the most boards out of a log. The log is simply passed through the saw in parallel cuts.

As you can see, the entire process is built for speed. Unfortunately, this sets the stage for the instability that frustrates builders in the Bay Area.

Why Flat-Sawn Boards Warp Easily

While flat-sawing is efficient, it creates the least stable boards. The growth rings run almost parallel to the wide face, making the board very sensitive to humidity changes.

As the board absorbs and releases moisture, it expands and contracts unevenly. This movement is why flat-sawn boards are known for cupping—curving across the face into a U-shape. This is all related to the critical role of wood moisture in stability.

More Stable (But Harder to Find) Cuts

For projects where stability is critical, other sawing methods are far better. You’ll almost never find them at a big-box store because they cost more to produce.

- Quarter-Sawn: The log is cut into quarters, then each quarter is sawn to create boards with straight grain lines. These are very stable and resist cupping.

- Rift-Sawn: This is the most stable and most expensive way to cut a log. Boards are milled radially from the center, creating a perfectly straight grain prized for high-end work.

According to the National Association of Home Builders (NAHB), callback costs due to material failures are a significant concern for builders. Using unstable lumber is a leading cause of these expensive repairs.

How Truitt & White Delivers Straighter, Better Lumber

When your reputation is on the line, you can't afford to gamble on materials. At Truitt & White, we understand that professional builders in Berkeley and Oakland need clean, straight, and reliable lumber every single time.

Unlike big-box stores, we are selective. We carefully source our lumber from reputable mills known for slower-growth trees and proper kiln-drying techniques. This first step ensures our wood starts out with better stability.

What to Expect from a Professional Berkeley Lumberyard

Once lumber reaches our Berkeley facility, our commitment to quality continues. Our materials are stored properly to prevent moisture absorption that leads to warping.

Our hands-on approach is what truly sets us apart:

- Rigorous Inspection: Our yard staff personally inspects materials to ensure they meet the high standards our professional clients expect.

- Hand-Picking Welcome: We believe you should see what you're buying. We let pros or homeowners pick their own boards for their project.

- Expert Guidance: Our team can help you find the right grade and species for the job, including sustainably sourced and engineered options that offer superior strength.

You don't have time for the lumber lottery. Partnering with a supplier that grades, stores, and stands behind its materials saves you hours on the job site and protects your bottom line.

Your Trusted Local Supplier for Bay Area Projects

If you’re building in Berkeley, Oakland, or the East Bay, skip the frustration at chain stores. Come see why Truitt & White is the trusted local supplier for clean, straight, builder-grade lumber that’s ready to work as hard as you do.

Frequently Asked Questions About Lumber Quality

Here are answers to common questions we hear from builders around the Bay Area.

How do I check a board for straightness at the lumberyard?

The best method is to "sight" the board. Hold one end at eye level and look down the edge and face. This is the fastest way to spot a crown (a bow along the edge), a cup (a U-shape across the face), or a twist.

Can I use a slightly warped board?

It depends. For non-structural uses like fire blocking, a board with a slight curve might be fine. For critical parts of a build like framing walls or setting joists, you should always use the straightest, most stable boards you can find.

Does storing lumber correctly on my Bay Area job site matter?

Yes, it matters a lot. You can buy the best lumber, but if you store it poorly on-site, it can still warp. Keep lumber stacked neatly off the ground on a flat surface and use "stickers" (small pieces of scrap wood) between layers to let air circulate.

Is engineered lumber a better choice to avoid warping?

For absolute stability, engineered lumber is the answer. Products like Laminated Veneer Lumber (LVL) are manufactured to be incredibly strong, straight, and stable. They are an excellent choice for headers, beams, and long-span floor joists.

What is the best lumber for framing in the Bay Area?

For most framing projects in Berkeley, Oakland, or San Francisco, Douglas Fir is the top choice. It offers an excellent combination of strength, stability, and workability, making it ideal for the region's building codes and climate. We carry high-quality, straight Douglas Fir for reliable results.

For clean, straight, builder-grade lumber for your next project in Berkeley, Oakland, or the greater Bay Area, trust the experts. Visit Truitt & White to see the difference quality materials and expert service can make.

Connect with us today for a quote or expert advice.