There’s nothing more frustrating than getting a lumber delivery only to find warped, split, or unusable boards. It’s a reality that costs Bay Area builders real time and money. The main reason why some lumber is warped or unusable when it arrives is due to moisture changes, but it's often a mix of milling, handling, and poor storage. These issues cause wood to twist, bow, or cup long before it reaches your job site.

The High Cost of Bad Lumber on Bay Area Projects

For contractors in Berkeley, Oakland, and across the Bay, a bad load of lumber isn't just a headache—it's a direct hit to the bottom line. The frustration is real: a bad delivery can derail a project or cost hundreds in culling and replacements. Many builders report cull rates as high as 60% from some suppliers, turning profitable jobs into losing ones.

Too often, buyers assume all lumberyards follow the same quality standards or they skip inspecting materials upon delivery. This common misstep can lead to rework, structural issues, and costly callbacks. With material prices always fluctuating, every board counts now more than ever.

Understanding Common Lumber Defects

A bad load of lumber can usually be traced back to one of these common culprits.

| Cause | What's Happening | Where It Happens |

|---|---|---|

| Moisture Content | Wood absorbs or releases moisture, causing it to swell, shrink, and warp. | From the mill to your job site. |

| Drying Method | Improper or rushed kiln-drying "case hardens" wood, locking in stress. | At the lumber mill. |

| Species & Grade | Lower-grade lumber has more defects; some species are just less stable. | During the milling and grading process. |

| Handling & Storage | Poor stacking or exposure to rain at the yard compromises quality. | At the supplier's lumberyard. |

| Shipping Damage | Boards get broken, scraped, or damaged by forklifts during transit. | On the truck, on the way to you. |

The Importance of a Reliable Supplier

In today's market, quality-conscious builders know that a supplier's reliability is everything. Inconsistent output from the mills and shaky supply chains have made it essential to partner with someone you trust to manage quality control. Getting it right the first time means your project stays on schedule and, more importantly, on budget.

This is why a dependable construction materials delivery service is so critical. It’s not just about getting materials to your site, but getting usable materials there.

At Truitt & White, we get it. Your project's success starts with the quality of the materials you use. Our team is trained to spot and flag defects before they ever leave our Berkeley lumberyard, which cuts down on waste and makes sure you get the quality you paid for.

Choosing a supplier that lets you hand-pick boards or that pre-sorts for quality is one of the best moves you can make. It protects your investment and avoids the common headaches of warped and unusable lumber.

The Main Cause of Warped Lumber: Moisture

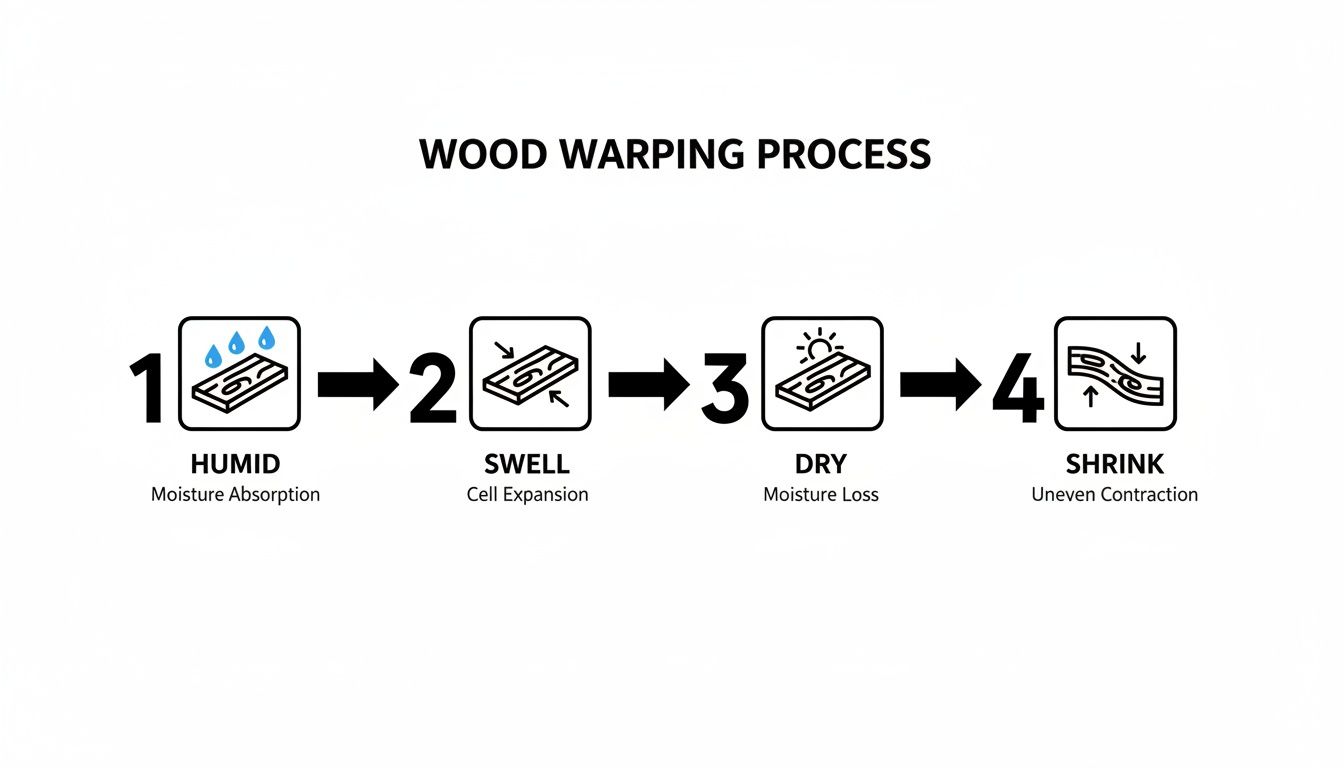

The number one reason a straight board turns into a twisted mess is moisture. Wood is a natural material made of tiny fibers that act like straws. They soak up moisture from the air and release it, causing the wood to constantly swell and shrink.

When the air is damp—like a classic San Francisco foggy morning—the wood fibers drink in moisture and swell. When the air is dry and warm, like an East Bay summer day, they release that moisture and shrink. This endless cycle is what causes lumber to cup, bow, twist, and warp.

Equilibrium Moisture Content (EMC) in the Bay Area

Wood is always trying to match its internal moisture level with the humidity of the air around it. This balance is called Equilibrium Moisture Content (EMC). A board milled and dried in a different climate, like Oregon, will immediately start adjusting to the unique humidity of Berkeley or Oakland upon arrival.

This adjustment period is where the trouble starts. If one side of a board is exposed to the sun and dries out faster than the other, it will shrink unevenly, causing it to cup or bow. This is a huge reason why some lumber arrives already warped; it’s been fighting a losing battle against moisture changes during shipping and storage.

Common Types of Warping to Look For

The way a board deforms depends on what part of the log it was cut from and how it gains or loses moisture. Here are the main culprits you’ll encounter:

- Cup: The board bends up at the edges, creating a "U" shape across its width. This often happens with flat-sawn boards when one face dries out faster than the other.

- Bow: The whole board curves along its length, looking like a banana.

- Twist: The ends of the board twist in opposite directions, like a propeller. This one is a real pain to work with.

- Crook: The board bends along its narrow edge. You might also hear this called an "edge bend."

If you want to dig deeper into how moisture specifically affects wood, this guide to understanding the causes of cupping in wood is a great resource. Ultimately, managing moisture is critical, and you can learn more in our guide on what vapor barrier insulation is and how it protects the building envelope.

The Lumber Journey: From Forest to Foundation

The quality of a board is decided long before it lands on your Bay Area job site. To understand why some lumber arrives warped, you have to look at its journey from the forest to the mill and finally to the yard. These early stages either lock in a board’s stability or compromise it.

The Critical Role of Milling and Drying

It all starts with the tree. Different species have different characteristics. Douglas Fir, for instance, is a local workhorse known for its strength and stability, making it a reliable choice for framing jobs all over Berkeley and Oakland.

After a log is milled into boards, it's saturated with water and must be dried. The best method is kiln-drying, which uses a controlled oven to bring the moisture content down. If this process is rushed, it can lock immense stress inside the wood, creating a board that looks straight on the pallet but is waiting for a humidity change to twist and warp.

Understanding Lumber Grades

Once dry, lumber is inspected and sorted by quality. Every board gets a grade stamp that tells you its strength, appearance, and intended use. Knowing how to read these grades is key to getting the right material.

- Select Structural, #1, and #2: These are your primary grades for framing. #1 has smaller, tighter knots than #2, making it stronger and straighter.

- Stud Grade: This lumber is meant for vertical use in walls, with grading rules tailored for that purpose.

- Economy: This is the lowest grade, often full of defects and not suitable for structural use.

A reliable supplier is your last line of defense in this journey. Smart construction supply chain management isn't just about moving materials; it’s about protecting their quality every step of the way.

How Your Supplier's Storage Practices Affect Quality

The lumberyard is the final guardian of quality before a board hits your Bay Area job site. A supplier's storage and handling can either preserve the stability achieved at the mill or ruin it completely. Improper storage is a primary reason why some lumber arrives warped and unusable. Stacks left uncovered and exposed to Berkeley’s fog or Oakland’s direct sun will quickly change moisture content unevenly, causing defects.

Best Practices for Lumber Storage

A professional supplier knows that protecting their inventory means protecting your project. Here are the key storage practices to look for:

- Indoor or Covered Storage: Keeping lumber out of the elements is non-negotiable. This prevents direct rain saturation and shields boards from the sun, which helps stabilize their moisture content.

- Proper Stacking: Lumber should always be stacked flat on level ground with small pieces of wood (stickers) placed between layers. This promotes even airflow around every board, allowing the stack to acclimate uniformly.

These practices ensure the lumber you receive is as straight and stable as the day it left the mill. For a deeper dive into specialized wood, check out our guide on what treated lumber is.

The Truitt & White Quality-First Promise

A supplier's commitment to quality also extends to how lumber is handled during transport. Using advanced equipment like automated pallet wrapping machines for consistent load security can prevent shifting loads and damage during transit. It's a small detail that makes a big difference.

At Truitt & White, every order is backed by a quality-first promise. Our lumber is stored indoors or protected from weather, and staff will pre-sort or let contractors hand-pick boards.

Our experienced team flags defects before they reach your site, reducing waste and callbacks. Our goal is to ensure that the lumber arriving at your project is ready to perform.

Your On-Site Lumber Inspection Checklist

Knowing how to spot and refuse a bad load of lumber on the spot protects your timeline and budget. Always inspect your delivery before the truck is unloaded. This simple habit can save you countless hours and hundreds of dollars.

One of the biggest mistakes is accepting a delivery without checking it, only to find warped studs later. Don't fall for low quotes that result in culling half the load. A few minutes of inspection protects you from these costly headaches.

What to Look for During Inspection

You don't need fancy tools to spot common defects. Grab a few boards from different parts of the stack and give them a quick once-over.

Here’s what you’re looking for:

- Warping (Bow, Cup, Twist, Crook): "Sight" the board by holding one end up to your eye and looking down its length and edge. Any curves or twists will be obvious.

- Knots: Small, tight knots are usually fine. Watch out for large, loose knots—anything over a third of the board's width—as they create weak points.

- Splits and Checks: Look for long cracks running with the grain, especially near the ends. These cracks compromise the wood’s structural integrity.

Beyond individual boards, assess the entire delivery. A quality supplier in the Bay Area will deliver lumber that looks fresh from the mill. This process is a cornerstone of any successful project, as outlined in our construction quality control checklist.

How to Choose a Reliable Lumber Supplier

Finding the right lumber supplier is about more than just price; it’s about building a reliable partnership. A great supplier is your first line of defense against the warped boards that lead to frustrating callbacks and wasted material. Their job is to ensure you get high-quality, usable lumber every time.

Key Questions for Your Supplier

Before placing an order, ask a few smart questions to gauge their commitment to quality. A professional, trustworthy yard will be proud to show you how they operate.

- How do you store your lumber? The answer should be "indoors" or "covered and stickered." Lumber sitting outside exposed to Bay Area weather is a major red flag.

- Can I inspect or hand-pick my order? A supplier who says "yes" is confident in their inventory and committed to your satisfaction.

- What is your return policy for unusable boards? A good partner stands behind their product with a clear, hassle-free process for swapping out defective material.

The Truitt & White Difference

At Truitt & White, we have built our reputation on quality. Serving Berkeley, Oakland, and the greater Bay Area, we are the trusted local partner for reliable lumber. All our lumber is stored indoors, shielded from the elements to keep it stable and straight.

We welcome contractors to hand-pick orders, but our experienced yard crew already culls bad boards before they are loaded for delivery. This proactive approach dramatically reduces your cull rate, saving you time and money. Stop by our Hearst Avenue yard to see our quality standards in action—or contact us for help sourcing the right lumber for your job.

Frequently Asked Questions (FAQs)

What is the fastest way to check a board for warp?

The fastest way is to "sight" it. Hold one end of the board up to your eye and look down its length and edges. Any bow, cup, crook, or twist will be immediately visible.

Should I let my lumber acclimate on the job site?

Yes, absolutely. For interior materials like trim, flooring, or cabinets, allow the lumber to sit in the room where it will be installed for several days. This lets its moisture content stabilize to the home's environment, preventing shrinking or swelling later.

Can I still use a slightly warped board?

It depends on the application. A framing stud with a slight bow can often be straightened during installation. However, severely cupped, twisted, or bowed boards should be culled, as forcing them into place can cause structural or finish problems.

Why is kiln-dried lumber better than green lumber?

Green lumber has a very high moisture content and will shrink and move significantly as it dries. Kiln-dried (KD) lumber has been dried to a stable moisture level, making it far more predictable and suitable for construction in the Bay Area.

What does the stamp on lumber actually tell me?

The grade stamp is the board's resume. It identifies the mill, the wood species (e.g., DF for Douglas Fir), the grade (#1, #2, etc.), and its moisture content when milled (e.g., KD for kiln-dried).

When you need lumber that’s straight, reliable, and ready for work, you can trust the team at Truitt & White. We make sure every board that leaves our yard meets our standards, so you can minimize waste and keep your project moving. Stop by our Berkeley showroom for some expert advice.